Blog

Here you can read more about the latest building design technologies. We’ve been writing blogs and articles on several BIM technologies.

- Home

- Blog

BIM Adoption for Residential Construction

Is BIM Adoption Slow in Residential Architecture? Home Blog How come residential architectural projects have...

Read MoreBIM for Infrastructure: Future of Roads, Bridges, & Utilities

Building Information Modeling for Infrastructure : Comprehensive Guide Home Blog Infrastructure – the very arteries...

Read MoreComparison of BIM Modeling in Various Typologies

Comparison of BIM Modeling in Various Typologies Home Blog The Building Info Bonanza: How BIM...

Read MorePreserving History with BIM: Modern Approach to Heritage Protection

BIM for Heritage Preservation – Future of Protecting Our Past Home Blog Think of a...

Read MoreBIM for Sustainability and Energy Efficiency Modeling

BIM for Sustainability and Energy Efficiency Modeling Home Blog We’re diving deep into the world...

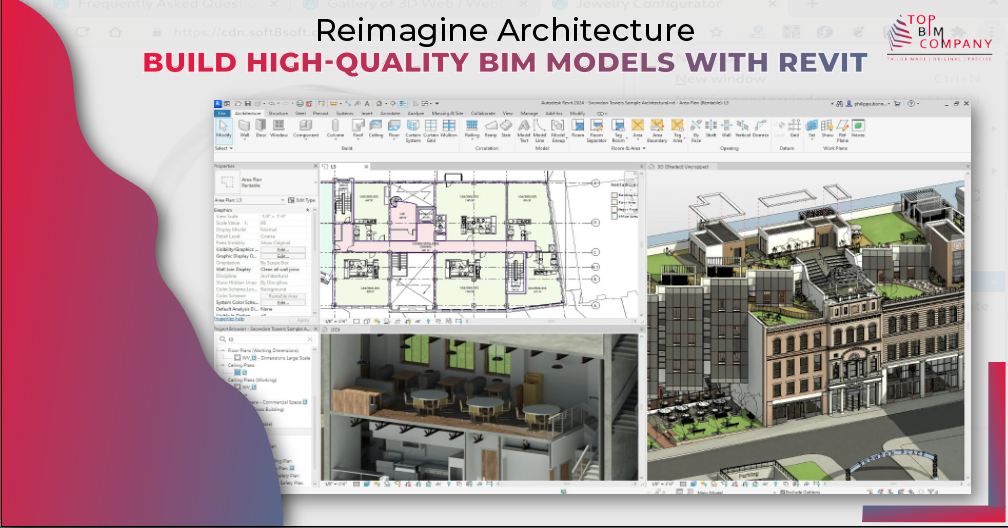

Read MoreCreating High-Quality Architectural BIM Models with Revit

Creating High-Quality Architectural BIM Models with Revit Home Blog Ever wondered how architects create...

Read MoreRole of GIS for Disaster Management Overview

GIS for disaster management Home Blog Scientific and technological advancements in particular provide a...

Read MoreGIS for Urban Planning | Application, Tools & Benefits

GIS for Urban Planning | Application, Tools & Benefits Home Blog What is Urban Planning? ...

Read MoreBIM in the USA: Transforming the Construction Industry

BIM in the USA: Transforming the Construction Industry Home Blog The construction industry in the...

Read MoreHow TopBIM Leverages Use of AutoCAD in BIM Era

How TopBIM leverages the use of AutoCAD in BIM’s era Home Blog With the...

Read MoreHow BIM Growing in Europe Construction Industry?

BIM Revolutionizing Construction in Europe: Comprehensive Guide Home Blog Significance of BIM in the European...

Read MoreHow is BIM growing in the Indian Construction Industry?

How is BIM growing in the Indian Construction Industry? Home Blog Building Information Modeling (BIM)...

Read More