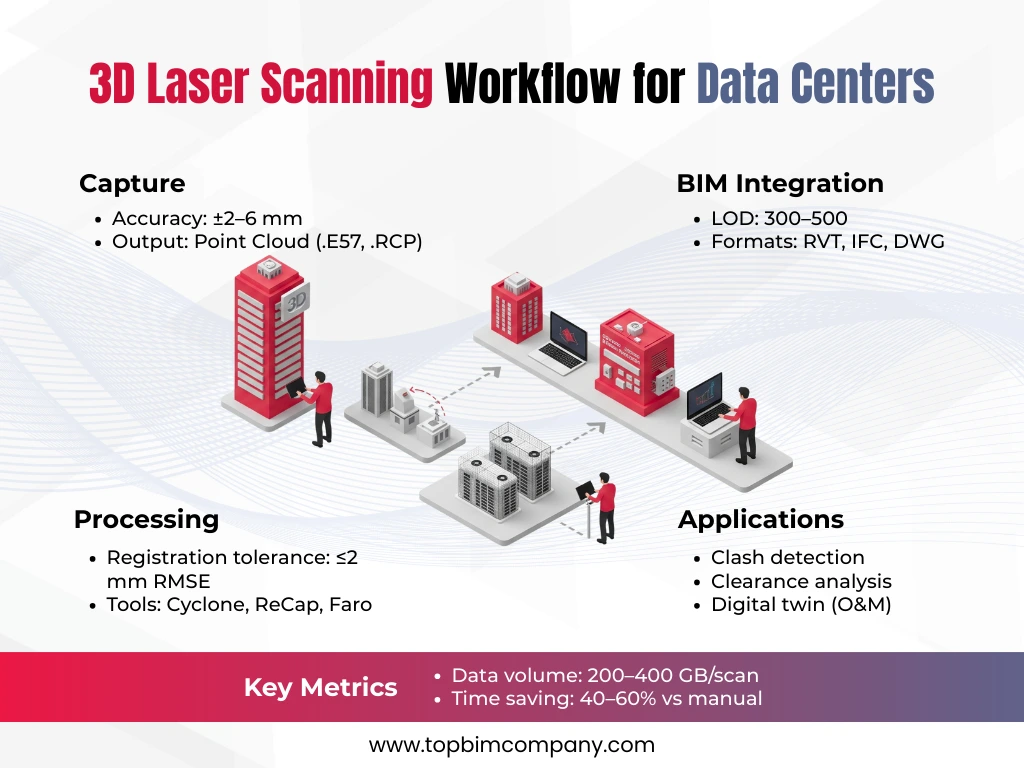

Laser scanning construction technology has reshaped how we handle data center projects with unmatched precision. This advanced technology captures detailed surface data quickly and creates highly accurate digital models that achieve 2-4mm precision in most cases. The technology uses lasers to measure objects and spaces, which helps us document existing conditions and plan new installations accurately.

Table of Contents

ToggleThe advantages of 3D laser scanning construction go well beyond precision alone.

Projects can see cost reductions up to 20%, while worker safety improves because measurements can be taken from secure locations.

The resulting point clouds give exact measurements between any two points, especially when you have data center environments where space usage and system integration matter most. The digital models from 3D laser scanning convert smoothly into 2D CAD drawings or 3D BIM models. These models are a great way to get insights for planning, construction, and ongoing management of complex data center facilities. This piece explores the complete workflow, tools, and real-world applications of this game-changing technology in data center environments.

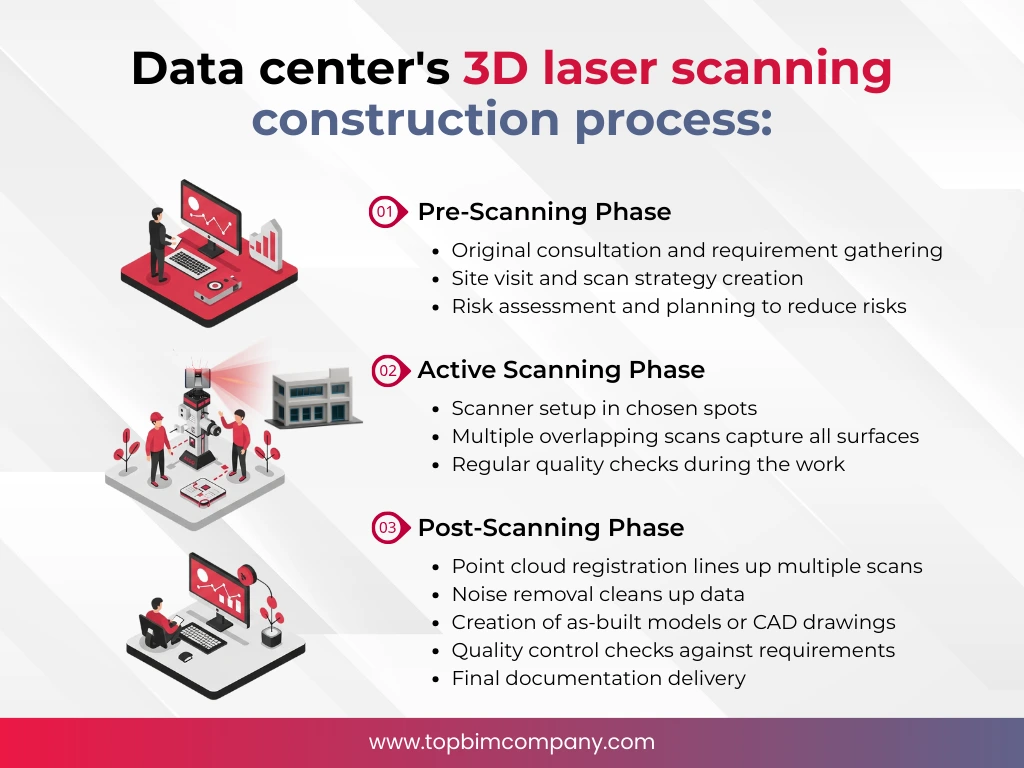

Step-by-Step Workflow for Data Center Laser Scanning

A successful laser scanning project in data centers needs a well-laid-out workflow. This will give a precise and efficient outcome. The process moves from careful preparation to final deliverables and quality checks.

Checklist

You need a complete pre-scan checklist before starting any laser scanning work in data center construction projects:

- Site assessment and planning: Review the data center space, spot possible obstacles, and pick the best scanner locations.

- Equipment preparation: Adjust all scanning hardware, check battery levels, and make sure there’s enough storage for point cloud data.

- Safety protocol review: Create safety steps for working near live equipment. Make sure team members know what to do in emergencies.

- Reference point establishment: Place survey control points across the facility. This helps line up multiple scans correctly.

- Stakeholder notification: Let data center staff know about scanning work and any access limits.

- Technical requirements confirmation: Check the needed detail level, accuracy specs, and file formats for deliverables.

This ensurese point cloud modeling meets technical needs and causes minimal disruption. The systematic approach helps data center updates and expansions. It forms the base for or accurate clash detection with 3D scanning and stops work from getting pricey during implementation.

Key Tools and Technologies Used

Picking the right hardware and software tools plays a huge role in making laser scanning construction projects successful in data centers. Today’s 3D laser scanners come with different capabilities that work well in various data center settings.

The Leica RTC360 terrestrial laser scanner captures two million data points every second with 2-6mm accuracy. It creates colorized point clouds and HDR imagery in just 2 minutes per scan location. The Trimble X9 3D laser scanner comes with auto-calibration and self-leveling features. These features help you maintain consistency in complex data center environments.

Handheld devices like the Leica BLK2GO let you scan from a first-person point of view. These work great when you need to move between server racks. On top of that, autonomous flying scanners help you capture hard-to-reach areas safely.

Evaluating Laser Scanning Technologies: Strengths and Limitations

Scanner Type | Pros | Cons |

Terrestrial Laser Scanners | • High accuracy and precision | • Limited mobility in tight spaces |

Mobile Scanners | • Excellent for confined spaces | • Typically lower accuracy |

Structured Light Scanners | • Can capture color information | • Don’t deal very well with shiny/dark surfaces |

So your choice between these technologies depends on your data center project’s specific needs. Terrestrial scanners give you better accuracy for large-scale documentation. Mobile solutions shine in update projects where space is tight.

The software that supports these scanners matters just as much. Platforms like Reality Cloud Studio make registration and meshing automatic. This cuts down the time needed for point cloud modeling in data centers.

Applications in Data Center Design, Maintenance, and Upgrades

3D laser scanning helps data centers through their entire lifecycle, from original design to regular maintenance. More data center owners now use this technology because it works well in many aspects of facility management.

Case examples

- Design and Expansion

Hyperscale Cloud Provider

During a hyperscale data center expansion in Ashburn, Virginia (Data Center Alley), engineers used 3D laser scanning and point cloud modeling to create a digital twin of the existing facility. This allowed them to map new electrical busways and cooling ducts without disrupting server operations. By simulating different design scenarios in BIM, they reduced potential clashes and accelerated approvals.

- Infrastructure Upgrades

Financial Services Data Center (New Jersey)

Before a major power upgrade, a financial institution commissioned a full 3D scan of its live data center. The scans revealed hidden cable trays behind overhead ducts that were missing from outdated 2D drawings. Detecting these early helped avoid weeks of rework and prevented downtime for mission-critical banking systems.

- Preventive Maintenance

Telecom Data Center (Dallas, TX)

A telecom provider uses quarterly 3D scanning to monitor structural shifts, rack alignment, and floor loading. Subtle settling of raised floors was detected within the first year, allowing them to reinforce support structures before it became a safety issue. The proactive scans saved millions by avoiding an unplanned shutdown.

- Retrofit and Expansion Projects

Colocation Provider (Chicago, IL)

When upgrading its colocation facility, the provider leveraged laser scanning and BIM integration to pre-plan installations of new CRAC (Computer Room Air Conditioning) units. Using millimeter-accurate models, contractors prefabricated piping and ductwork offsite, cutting installation time by 30% and avoiding on-site clashes.

- Compliance and Documentation

Government Data Center (Washington, D.C.)

For compliance with ISO 27001 and SOC 2, a government-run data center used 3D scanning to maintain a precise as-built record. The models supported both security audits and facility management, ensuring all modifications were properly documented for regulatory purposes.

Accuracy, Compliance, and Safety Considerations.

Laser scanning construction demands high precision to work effectively in data centers. Today’s 3D laser scanners achieve accuracy within ±2 millimeters.

- The environment and distance affect these measurements significantly. To name just one example, the Leica RTC360 provides 3D point accuracy of 1.9mm at 10m, 2.9mm at 20m, and 5.3mm at 40m.

- This scanner’s capabilities make it perfect for detailed as-built documentation with 3D scanning.

- Data center operations must follow strict regulatory standards. These facilities run under tight regulations that control information security and operational protocols.

- Data centers typically need to comply with standards like ISO 27001, SOC 2, PCI DSS, HIPAA, and GDPR. These requirements call for detailed documentation of scanning methods.

- Point cloud modeling in data centers demands unwavering attention to safety.

- The technology makes the workplace safer by limiting worker exposure to dangerous or confined spaces. In spite of that, eye protection is a vital requirement – particularly with Class 3R laser systems that need designated safety officers.

- The scanning process needs to factor in environmental elements like temperature changes, dust, and reflective surfaces.

- Teams should verify calibration regularly. Reference measurements taken at project start and end help maintain data quality throughout the scanning work.

Start building a sustainable future today. Get free 3D Laser Scanning consultation for your project.

Common Mistakes in Data Center Laser Scanning

Modern technology hasn’t eliminated avoidable mistakes in laser scanning construction projects. Data center scanning errors usually stem from poor preparation, not equipment limitations.

- Poor planning of scanner locations results in blocked views and missed critical areas. Teams often forget backup equipment. Missing spare batteries, memory cards, and tools can disrupt the whole scanning process.

- Wrong scanner positions create major problems. Bad angles and incorrect placement distort geometry and lose data. Gaps between scan stations leave “holes” in hidden areas like ceiling corners or behind obstacles.

- The surrounding environment changes the results. Shiny surfaces interfere with data by creating specular reflections. Changes in cooling system temperatures make measurements less accurate. Scanning teams should work with facility managers to pick the best scanning times.

Tips to avoid them

Quality and reliable point cloud modeling for data centers requires:

- Drawing a scan map helps track locations and provides reference points to arrange scans

- Opening doorways before scanning captures more data

- Removing people from scanner’s view improves results

- Keeping objects in fixed positions between scans matters

- Adding targets and control networks helps registration

- Setting up survey control before scanning connects data with project control

Good preparation remains the best way to reduce errors when documenting as-built conditions with 3D scanning.

Conclusion

The growing integration of 3D laser scanning in data centers is more than a technical upgrade it’s a strategic shift in how critical facilities are designed, operated, and sustained. By capturing reality with millimeter-level precision, teams aren’t just avoiding rework or clashes; they are building a digital foundation that supports resilience, compliance, and future scalability. This signals an industry moving toward proactive decision-making, where every retrofit, expansion, or maintenance activity is informed by reliable spatial intelligence.

In essence, 3D laser scanning is evolving from a support tool to a core enabler of data center competitiveness. As hyperscale and mission-critical environments demand ever-greater efficiency, safety, and uptime, the organizations that harness reality capture will set the benchmark for operational excellence and long-term cost savings. The inference is clear: in the race to build smarter, faster, and safer data centers, laser scanning isn’t optional it’s inevitable.

Frequently Asked Questions (FAQs):

Q1. What is 3D laser scanning in data centers?

It is a technology that uses lasers to capture millions of data points and create precise digital models of data center environments.

Q2. How accurate is 3D laser scanning for data centers?

Most modern scanners deliver ±2–6 mm accuracy, suitable for detailed as-built documentation and clash detection.

Q3. What are the main benefits of 3D laser scanning in data centers?

It reduces costs by up to 20%, speeds up project timelines, improves safety, and provides reliable documentation for upgrades and compliance.

Q4. What is the workflow of a typical 3D laser scanning project?

It includes pre-scanning (planning, safety, control points), active scanning (multiple scans, quality checks), and post-scanning (registration, noise removal, deliverables).

Q5. What deliverables are generated from laser scanning?

Deliverables include point clouds (.E57, .RCP), 2D CAD drawings, 3D BIM models (RVT, IFC, DWG), and digital twins.

Q6. Which laser scanners are best for data center projects?

High-precision terrestrial scanners (e.g., Leica RTC360, Trimble X9) for large spaces, and mobile/handheld scanners (e.g., Leica BLK2GO) for confined rack areas.

Q7. How does 3D laser scanning enhance safety in data centers?

It reduces worker exposure to hazardous or confined spaces and enforces laser safety protocols such as protective eyewear.

Q8. Can 3D laser scanning help with compliance?

Yes, it provides accurate as-built records that support audits and certifications like ISO 27001, SOC 2, HIPAA, PCI DSS, and GDPR.

Q9. What are common mistakes in data center scanning?

Poor scanner positioning, lack of backups, blocked views, and issues with reflective surfaces are the most frequent errors.

Q10. Why is 3D laser scanning becoming essential for data centers?

Because it ensures precision, reduces downtime, supports compliance, and provides a scalable digital foundation for future upgrades.

Further Reading

How to Process Laser Scan Data and Select the Right Scanning Provider or Technology?

Ultimate Guide to 3D Laser Scanning & LiDAR Scanning

Comprehensive Guide on As-Built Surveys

How to Conduct 3D Laser Scanning in Data Centers and Choose the Right Tools?

How to Use As-Built Surveys in Renovation Projects and Avoid Common Mistakes?

How to Conduct an As-Built Survey and Choose the Right Tools for Your Project?

Our Services

Latest Post

Get A Free Quote

BIM Construction is the Future

Building information modeling (BIM) is the future of building design and construction. Get in touch with our BIM Experts.