Our MEPF engineering process ensures that the smallest carbon footprint is achieved, whether the design involves HVAC, lighting, plumbing, or fire protection.

At TopBIM Company, we offer top-notch MEPF (Mechanical, Electrical, Plumbing and Fire Protection) services to help our clients achieve maximum efficiency and productivity in their construction projects. Our team of experts is equipped with the latest BIM (Building Information Modeling) technology and tools to provide the most accurate and reliable MEP solutions.

We understand that MEP systems are critical to the success of any construction project, and that’s why we prioritize quality and efficiency in our services. Our MEP BIM drafting services are designed to help our clients save time and money by reducing errors, improving coordination, and enhancing overall project performance.

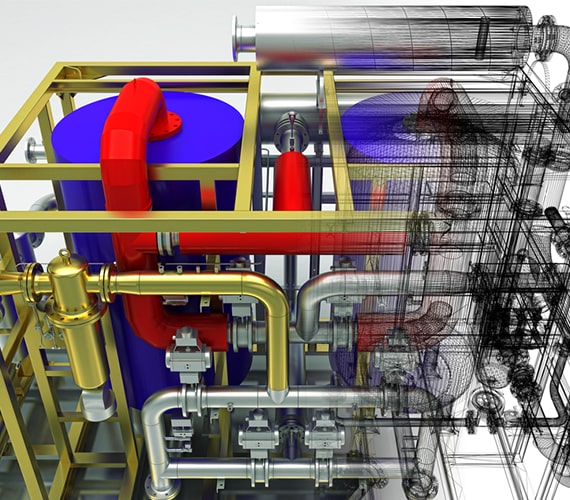

Through clash detection and coordination, BIM MEP clash detection services enable a clash-free BIM model for MEP construction to AEC clients, engineers, contractors and fabricators. The hassle-free installation of MEPF systems and their components in a building is made possible by identifying and resolving intra and interdisciplinary clashes. Using BIM, MEP engineers simultaneously plan and design the layout as opposed to the conventional method of designing just after routing and designing the full building plan.

Comprehensive designs and a methodical arrangement of MEP systems for installation in a building are shown in MEP design drawings created by an MEP business employing computer-aided design and building information modeling technologies. MEP drafting & drawing services accurately depict the component’s technical specifications as well.

Contrary to architects, structural engineers, MEP contractors and the O&M team have ongoing responsibilities for the smooth running of the facility. Drainage pipes, water distribution, sanitation, plumbing, building lighting, elevators, and HVAC system performance ratings all require periodic attention and maintenance. However, it becomes laborious to maintain numerous such minor parts throughout huge facilities like malls or airports. BIM models assist in change management and space planning by preserving the most recent updated information.

Get Accurate Revit MEPF Models as per Design and Fabrication Needs

MEPF coordination is frequently a time-consuming, difficult process that adds to project timeline delays. This is primarily due to information fragmentation and ineffective communication. There are several uses of the BIM modeling technology for MEP engineering services.

The use of MEP BIM in engineering projects boosts productivity by 58% and reduces costs by about 21% as per Autodesk. BIM’s contemporary design aids flawless building creation integrating MEP design.

Laser scanning data is exported and processed using BIM-based software.

Using Revit or other BIM software, the point cloud data is transformed into a data-rich MEP Building Information Model.

After it has been generated, the BIM model is audited for a number of things, including validity and clash detection.

After the audit, the inefficiencies are fixed, and a final product is produced and created for the client.

BIM makes it possible to relate MEPF coordination tasks like the smooth integration of MEPF systems into the architectural and structural envelope, creation of equipment matrices and supplier selection, scheduling of the installation and procurement of MEPF systems, tracking and formalization of submittal procedures, and the management of MEPF specialty contractors by the general contractor.

In essence, BIM addresses significant problems that MEP contractors frequently encounter during the planning stage.

MEP – a sophisticated system necessitates close coordination and attention to detail preventing errors, visualizing MEP workflow.

MEP designers manage several duties at once. Creating schematics for one component, while working on designs for another, extracting real-time information.

A one-stop solution for all needs related to BIM Consulting and Outsourcing Services

With the aid of BIM, necessary change orders during the design phase & alterations are executed virtually.

No need to repair damage after building component malfunction. Routine inspections & system modifications update MEP data in BIM. Keep track of MEP components, get accurate MEP estimation & plan for replacement in advance.

First, use the appropriate MEP BIM template. Activate MEP BIM Template before a new project. For each of the listed trades including mechanical, electrical and plumbing, the template should be based on the organization's standards.

Design that is interconnected and trans-disciplinary enables professional collaboration, data sharing, and control of interferences amongst the structural, architectural, and installation systems. Further, there is quick processing of project data and simple project editing.

There are several elements of MEP including pumps, chillers, fans, air handlers, motor control centres, distribution panels, transformers, and pipes, ductwork, and conduit used in distribution systems.

Building information modeling (BIM) is a sophisticated, 3D model-based method that aids MEP professionals in effective designing, detailing, documenting, and fabricating building systems. BIM helps project teams of MEP Company and MEP CAD services collaborate better, share data more quickly, and deliver projects more quickly from conception to completion.

Model-based Building Information Modeling (BIM) assists MEP professionals in designing, detailing, documenting, and fabricating building systems more efficiently.