Conducting an as-built survey accurately isn’t optional in construction, it’s essential. These detailed measurements and documentation of your completed project capture every change, modification, and final detail that happened during construction.

Table of Contents

ToggleThis guide is for construction professionals, project managers, architects, and surveyors who need to document their projects correctly and choose the right survey tools and equipment for their specific needs. Whether you’re working on residential renovations or large commercial builds, getting your as-built survey right saves time, money, and headaches down the road.

We’ll walk you through the complete as-built survey process from start to finish. You’ll learn how to select the right survey tools and technology for your project type and budget, and discover practical techniques for recording and documenting as-built data that meets industry standards. We’ll also cover proven methods to ensure accuracy and compliance throughout your surveying work.

What is the Purpose of an As-Built Survey?

Before diving into tools and processes, it’s important to understand why as-built surveys matter. In construction, no project is ever built exactly as it was designed on paper. Field conditions, unforeseen challenges, and design modifications all introduce changes during execution. Without capturing these adjustments, project teams are left relying on outdated drawings that don’t reflect the final reality of the structure. That’s where as-built surveys come in, they bridge the gap between design intent and actual construction, creating a reliable record of the finished project.

Why businesses and projects need it

- As-built surveys serve as critical documentation for businesses and construction projects by providing an accurate, as-is blueprint that reflects how structures exist after completion.

- Unlike original design plans, these surveys capture the reality of construction, including unplanned changes that quickly make as-designed documents outdated during the building process.

- The as-built survey process delivers essential benefits by eliminating reliance on outdated blueprints and assumptions that can compromise project success.

- These comprehensive records detail final utility locations, precise measurements, and actual materials used, accompanied by visual documentation through drawings or models.

- This accurate project documentation becomes indispensable for future renovations, maintenance, compliance verification, and any subsequent construction work on the site.

Start building a sustainable future today. Get free 3D Laser Scanning consultation for your project.

What Tools and Equipment Are Used in As-Built Surveys?

Laser scanners, LiDAR, GPS, Total Stations.

Modern as-built surveys rely on advanced surveying equipment like laser scanners to deliver measurements that are often more accurate than traditional manual methods.

- These sophisticated survey tools and equipment enable construction professionals to conduct as-built surveys with unprecedented precision during or after project completion, ensuring verified and accurate measurements before final documentation.

- The selection of appropriate surveying technology depends on project requirements, site conditions, and accuracy specifications.

- Each tool offers distinct advantages for different aspects of building documentation and construction surveying, making it essential to understand their capabilities when planning your survey approach.

Equipment | Primary Function | Accuracy Range | Best Use Cases | Key Advantages |

Laser Scanners | 3D point cloud capture | Sub-millimeter to 2mm | Complex structures, detailed interiors | High-density data, rapid collection |

LiDAR | Aerial/mobile mapping | 5-15cm | Large sites, terrain mapping | Wide area coverage, penetrates vegetation |

GPS | Position determination | 1-5m (standard), sub-meter (RTK) | Site boundaries, reference points | Global coverage, real-time positioning |

Total Stations | Angle and distance measurement | 1-5mm + 1-3ppm | Precise point surveys, layout work | Versatile, proven accuracy, established workflows |

How to Conduct an As-Built Survey Step-by-Step?

An as-built survey isn’t just about taking measurements, it’s about creating a systematic record of reality. To ensure accuracy and consistency, the process should be approached methodically, starting with preparation and continuing through fieldwork, documentation, and final review.

Below is a clear, structured workflow that outlines the essential steps and a practical checklist to guide your survey from start to finish.

Step 1: Define Scope and Requirements

- Establish the survey’s objectives: renovation, compliance, or facility management.

- Determine accuracy requirements based on project type.

- Identify deliverables (drawings, CAD files, BIM models).

Step 2: Gather Existing Documentation

- Collect original design drawings, previous surveys, and specifications.

- Highlight potential differences between design intent and current site conditions.

- Use this research to plan data capture effectively.

Step 3: Conduct Site Reconnaissance

- Walk through the facility to understand layout and conditions.

- Note obstacles, utilities, and safety risks.

- Set up reference or control points.

Step 4: Measurement and Data Collection

- Capture precise measurements using tools such as laser scanners, total stations, LiDAR, or GPS.

- Record elevations, dimensions, and spatial relationships.

- Document MEP (Mechanical, Electrical, Plumbing) and structural systems.

Step 5: Photographic Documentation

- Take detailed photographs from multiple angles.

- Link images to measurement points for clarity.

- Use photos as visual evidence to support dimensional data.

Step 6: Data Processing

- Convert raw measurements into CAD drawings or BIM models.

- Ensure that all deviations from original plans are documented.

- Maintain data in standardized formats for easy reference.

Step 7: Verification and Quality Control

Cross-check as-built documentation with both field data and original design drawings to identify and resolve discrepancies early.

Validate measurements against defined accuracy tolerances, such as:

- Interiors: ±5–10 mm

- Site boundaries: ±2–3 cm

- Aerial/Mobile LiDAR: ±5–15 cm

Reference recognized standards like ISO 19650 (BIM information management), RICS measured survey guidance, or the USIBD Level of Accuracy (LOA) to ensure compliance. Where applicable, integrate clash detection in BIM models and perform peer reviews to strengthen quality assurance

Step 8: Deliverables and Stakeholder Review

Prepare final documentation in agreed formats, whether annotated 2D drawings, CAD files, BIM models, or reports.

- Share deliverables with stakeholders for review and approval

- Maintain audit trails and version control for transparency

- Collect licensed surveyor sign-offs for accountability

- Archive records securely in a cloud platform or CDE

Now that we have covered the essential steps for conducting an as-built survey, creating a comprehensive field checklist becomes crucial for maintaining accuracy throughout the process.

Field Checklist for Accuracy

- Define survey scope, objectives, and requirements

- Gather existing documentation (plans, surveys, specifications)

- Conduct site reconnaissance (walkthrough and layout notes)

- Capture precise measurements & elevations

- Document MEP and structural systems with locations and conditions

- Take detailed photographs from multiple angles

- Process raw data into CAD or BIM models

- Verify accuracy against design and field data

- Prepare final deliverables (drawings, models, reports)

- Share with stakeholders and resolve queries.

How to Record and Document As-Built Data Effectively?

Previously, conducting as-built surveys relied heavily on traditional manual methods that were time-consuming and labor-intensive, requiring hand measurements, camera-only change capture, and manual data sorting.

- Today’s advanced surveying technology has revolutionized the as-built survey process through digital solutions that significantly reduce effort and time requirements.

- Modern as-built survey tools now include advanced laser scanning and 3D capture technology that delivers superior accuracy compared to traditional approaches.

- Digital Twin platforms like Matterport’s offer quick and accurate 3D scans using various compatible cameras or smartphones, often requiring less time than conventional laser scanning methods while maintaining precision standards.

Documentation Templates

With advanced surveying technology in place, Digital Twin platforms provide comprehensive documentation features that enhance project documentation efficiency. These platforms include measurement modes that enable users to pull accurate dimensions and generate TruePlan sketches, making data accessible online for authorized team members and improving collaboration.

Modern scans maintain compatibility with various platforms and file formats, enabling flexible delivery options for different construction surveying needs. For instance, e57 files provide detailed point clouds that can be manipulated in software like Autodesk Revit, ensuring seamless integration with existing workflows and construction survey tools.

Using standardized templates ensures consistency across projects and makes as-built data more valuable for future use.

A good as-built documentation template typically includes:

- Standardized Deliverables: Pre-formatted layouts for floor plans, elevations, and section drawings.

- Metadata Fields: Sections to note materials, conditions, or deviations from design intent.

- Compliance & QA/QC Checklists: Built-in prompts to verify code requirements and accuracy.

- Collaboration Options: Cloud-based templates that allow comments, markups, and team access.

- Visual Integration: Space to embed photos, scan snapshots, or links to 3D models.

By adopting structured templates, teams can reduce rework, maintain consistency, and make documentation more accessible for both current projects and future renovations.

How to Ensure Accuracy and Compliance in Your Survey?

Modern surveying technology drastically reduces the time and effort needed for as-built surveys while delivering accurate captures of existing buildings that meet survey requirements.

1. Quality Checks

Digital Twin platforms facilitate quick and accurate 3D scans using specialized equipment, offering features like measurement mode for precise dimensions that ensure survey accuracy throughout the documentation process.

- To further guarantee precision, surveyors often validate scan data against ground control points (GCPs), GPS benchmarks, or total station checks.

- Establishing defined tolerance thresholds, for example, ±5 mm for interiors or ±2 cm for site boundaries, ensures accuracy is not only claimed but measured against accepted limits.

- Additional practices such as peer review of data, clash detection when integrated into BIM, and real-time field validation reduce the risk of costly rework.

2. Industry Standards

- Digital solutions provide enhanced accessibility with models easily available online for authorized team members, ensuring compliance with industry documentation standards.

- These technologies integrate seamlessly with BIM and design software through compatible formats like e57 point cloud files, meeting professional surveying standards while enabling better resource allocation and more accurate predictions for construction projects.

- Compliance is further reinforced by aligning surveys with recognized frameworks such as ISO 19650 for BIM information management, RICS guidance on measured surveys, or the U.S. Institute of Building Documentation (USIBD) Level of Accuracy (LOA) specifications. Clear audit trails, sign-offs by licensed professionals, and version-controlled deliverables add another layer of accountability, giving stakeholders confidence that the documentation is both reliable and compliant.

How to Select the Right Tools and Technology for Your Project?

Guidance for decision-makers with ROI

Smart decision-makers approach as-built survey tool selection by calculating total cost of ownership against project benefits. High-end surveying technology like 3D laser scanners delivers faster data collection and superior accuracy, reducing field time by 60-80% compared to traditional methods. While initial investment appears substantial, the ROI becomes clear through reduced labor costs, fewer site visits, and minimized rework expenses.

- Construction survey tools selection depends on project complexity, timeline, and accuracy requirements.

- Small residential projects may justify basic equipment, while large commercial developments benefit from advanced surveying technology that captures comprehensive building documentation efficiently.

- Consider equipment rental for one-time projects versus purchase for ongoing survey operations to optimize your investment strategy.

Survey Tool Selection Checklist

- Assess project complexity (residential vs. commercial vs. infrastructure).

- Calculate ROI beyond purchase price (time savings, reduced rework, fewer site visits).

- Decide between renting or purchasing based on project frequency.

- Match tools to purpose:

- Laser scanners → detailed interiors & MEP.

- LiDAR → large terrains & infrastructure.

- GPS/GNSS → control points & georeferencing.

- Ensure interoperability with BIM and Digital Twin platforms.

- Plan for scalability and future-proofing (cloud integration, software upgrades).

- Consider ease of use and operator training needs.

- Account for hidden costs (maintenance, calibration, software, storage).

- Verify compliance with industry standards (ISO 19650, RICS, USIBD LOA).

Conclusion

As-built surveys are far more than just a technical formality, they are the foundation of accurate project documentation, informed decision-making, and long-term asset management. From choosing the right tools and technology to ensuring accuracy, compliance, and proper documentation, every step directly impacts project efficiency and ROI. Businesses that invest in structured survey processes not only avoid costly rework but also gain a reliable record that supports renovations, facility operations, and regulatory approvals.

In today’s construction landscape, where precision equals profitability, adopting best practices in as-built surveys is no longer optional, it’s a competitive necessity. By applying the right methods and leveraging modern digital solutions, project teams can bridge the gap between design intent and built reality, ensuring projects are delivered on time, on budget, and with complete confidence.

Frequently Asked Questions (FAQs):

Q1. What is the main purpose of an as-built survey?

The purpose of an as-built survey is to document the exact conditions of a completed project. It ensures that all design changes, modifications, and final construction details are recorded for compliance, renovations, and long-term facility management.

Q2. Why are as-built surveys critical in construction projects?

As-built surveys prevent costly rework, reduce site revisits, ensure compliance with standards, and provide accurate data for future design or maintenance work. They help bridge the gap between design intent and built reality.

Q3. What tools are commonly used for as-built surveys?

Surveyors use tools like laser scanners, LiDAR, GPS, and total stations. Each serves different purposes-laser scanners capture detailed interiors, LiDAR maps large terrains, GPS ensures accurate positioning, and total stations provide high-precision measurements.

Q4. How do I decide which survey tools are right for my project?

Tool selection depends on project size, complexity, accuracy requirements, and budget. For example, laser scanners are ideal for detailed interiors, while LiDAR is better for large outdoor sites. Smaller projects may benefit from basic GPS and total station setups.

Q5. What is the step-by-step process for conducting an as-built survey?

The process includes:

Defining scope and accuracy requirements

Gathering existing documentation

Conducting site reconnaissance

Capturing measurements and photos

Processing data into CAD/BIM models

Verifying accuracy and compliance

Delivering final documentation for stakeholder review

Q6. How do modern digital tools improve as-built surveys?

Digital solutions like 3D laser scanning, Digital Twins, and BIM integration reduce manual effort, improve accuracy, and enable real-time collaboration. They also allow cloud-based storage and version control for better accessibility.

Q7. What standards ensure accuracy and compliance in as-built surveys?

Industry standards such as ISO 19650 (BIM information management), RICS measured survey guidelines, and USIBD Level of Accuracy (LOA) are commonly used. These frameworks ensure surveys meet professional, legal, and regulatory benchmarks.

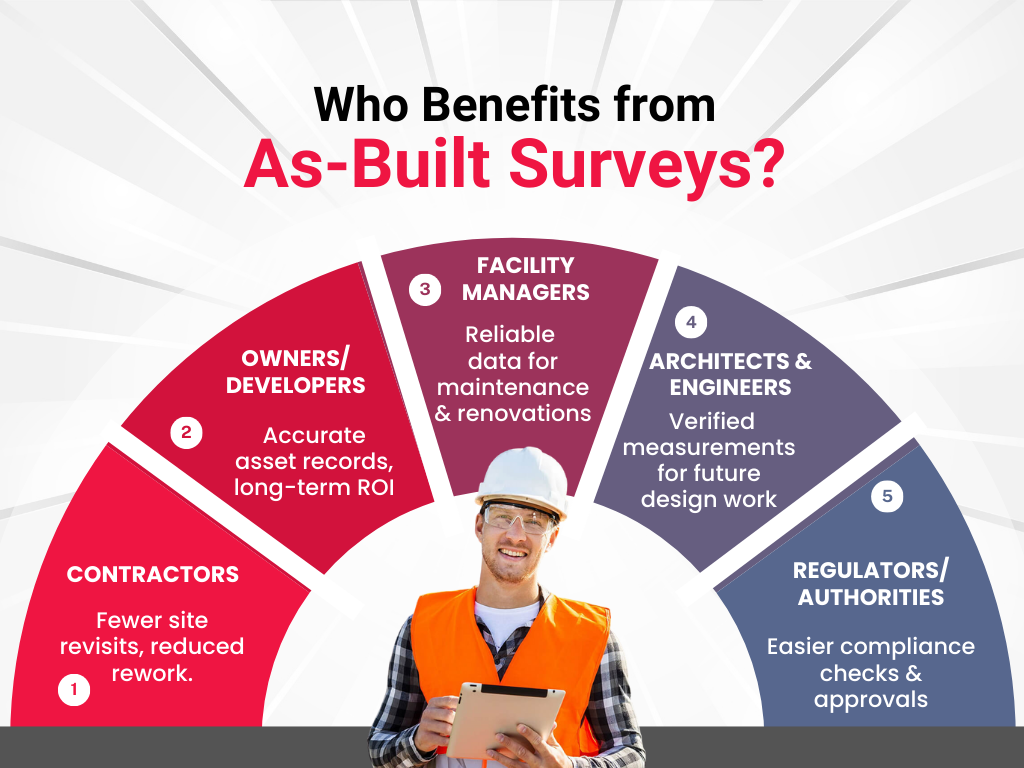

Q8. Who benefits most from as-built surveys?

Contractors benefit from fewer revisits, owners gain reliable asset records, facility managers use data for maintenance, architects and engineers get verified measurements for future work, and regulators streamline compliance approvals.

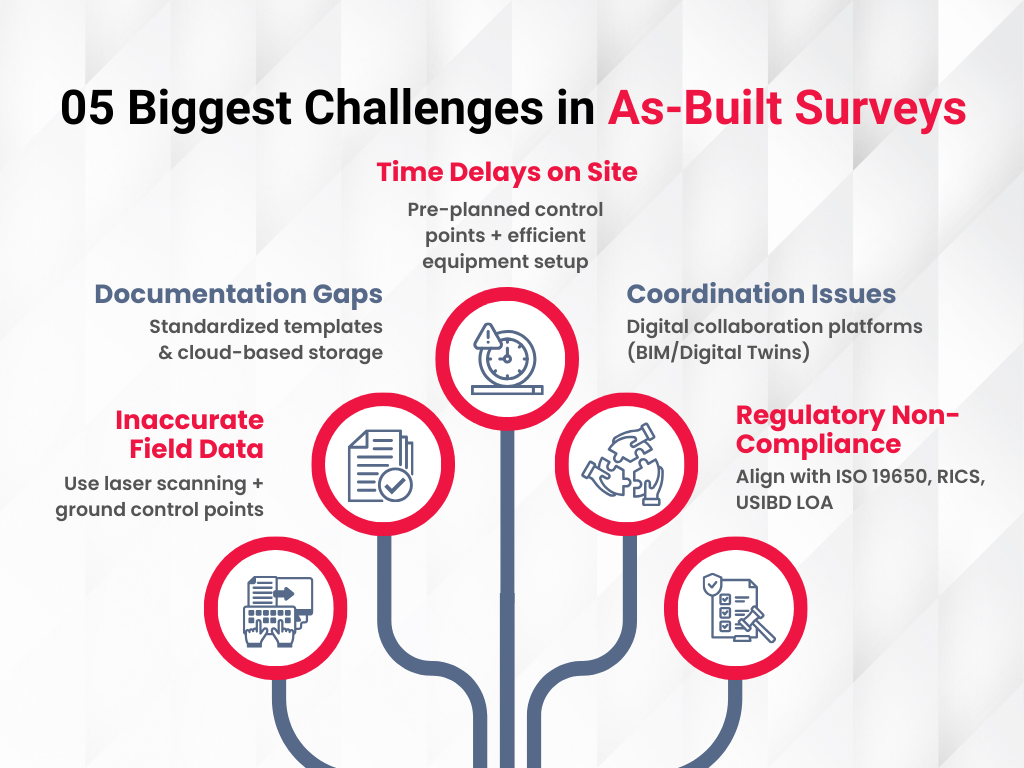

Q9. What are the biggest challenges in conducting as-built surveys?

Key challenges include inaccurate field data, documentation gaps, site delays, poor coordination, and regulatory non-compliance. These can be mitigated with digital tools, standardized templates, and structured workflows.

Q10. How do as-built surveys reduce overall project costs?

By preventing rework, minimizing errors, ensuring compliance, and streamlining future renovations, as-built surveys significantly cut costs and improve ROI across the project lifecycle.

Further Reading:

What is Laser Scanning in Surveying and How Can These Solutions Benefit Your Business?

BIM for Sustainability and Energy Efficiency Modeling

BIM for Heritage Preservation – Future of Protecting Our Past

Future-Proofing AEC Projects: The Role of BIM in Meeting Both ADA and OSHA Standards

Our Services

Latest Post

Get A Free Quote

BIM Construction is the Future

Building information modeling (BIM) is the future of building design and construction. Get in touch with our BIM Experts.