Data centers use up a huge 200 terawatt-hours of electricity each year, which makes up about 1% of the world’s electricity usage.

Table of Contents

ToggleSmart BIM strategy has become crucial for these facilities as we just need more space to store and process data.

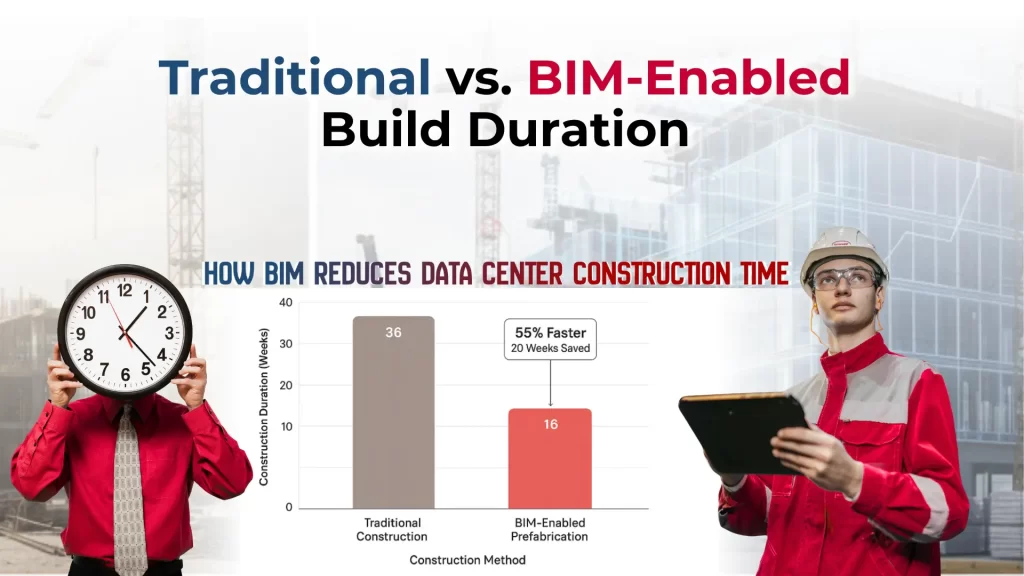

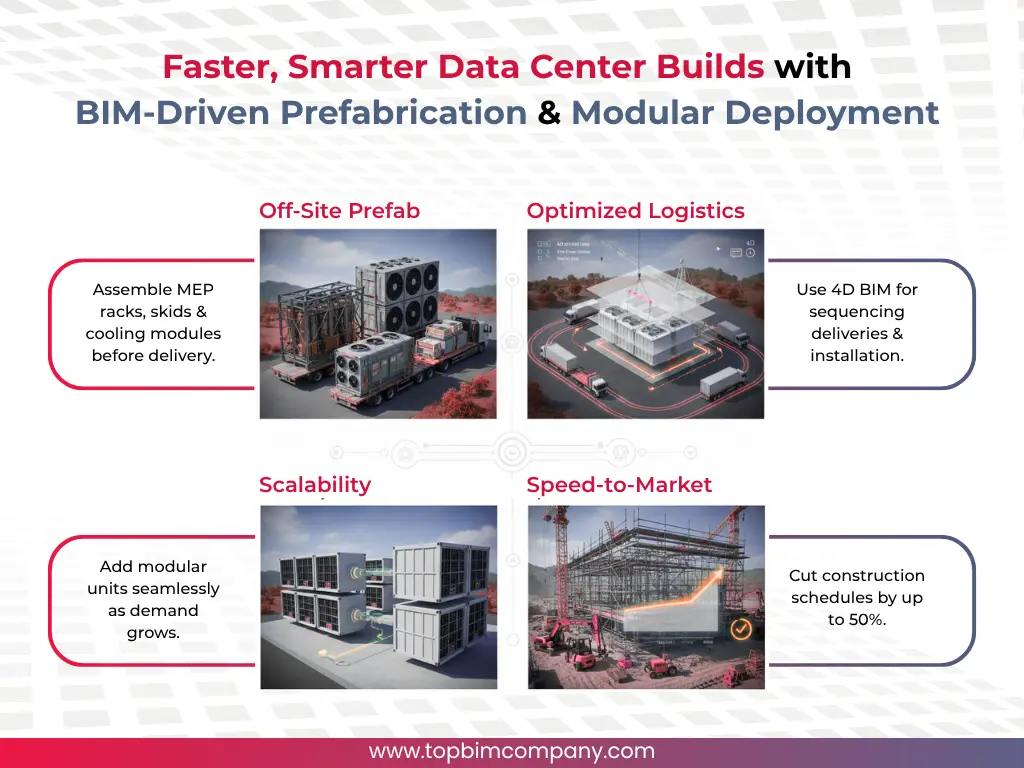

The modular data center market will grow from $23 billion in 2022 to $88.5 billion by 2030. This growth brings new challenges in designing and managing these complex facilities. BIM technologies are a great way to get better control over construction projects. This proves especially valuable for data center projects where every detail matters. BIM cuts down construction time by a lot – reducing on-site building from 36 weeks to just 16 weeks for prefabricated modular data centers.

BIM helps manage the resilient, redundant power systems that data centers need. The technology also lets teams plan heating and cooling systems better to cut down energy waste. On top of that, it gives facility managers useful data about energy usage over time, which leads to smarter operational choices.

This piece will get into how a detailed BIM strategy reshapes data center design, construction, and management. We’ll look at everything from clash detection to digital twins for operations. You’ll also learn how BIM coordination helps avoid those pricey chain reactions of mistakes that slow down work across different trades.

Data centers use up a huge 200 terawatt-hours of electricity each year, which makes up about 1% of the world’s electricity usage.

Smart BIM strategy has become crucial for these facilities as we just need more space to store and process data.

The modular data center market will grow from $23 billion in 2022 to $88.5 billion by 2030. This growth brings new challenges in designing and managing these complex facilities. BIM technologies are a great way to get better control over construction projects. This proves especially valuable for data center projects where every detail matters. BIM cuts down construction time by a lot – reducing on-site building from 36 weeks to just 16 weeks for prefabricated modular data centers.

BIM helps manage the resilient, redundant power systems that data centers need. The technology also lets teams plan heating and cooling systems better to cut down energy waste. On top of that, it gives facility managers useful data about energy usage over time, which leads to smarter operational choices.

This piece will get into how a detailed BIM strategy reshapes data center design, construction, and management. We’ll look at everything from clash detection to digital twins for operations. You’ll also learn how BIM coordination helps avoid those pricey chain reactions of mistakes that slow down work across different trades.

- Remote capture reduces exposure in hazardous zones

- Identify clearance issues before physical work begins

- Lower radiation exposure in nuclear facilities

- Minimize risks in high-temperature or pressurized areas

- Enhanced training with virtual walkthroughs

Key Challenges in Data Center Design & Construction

Modern data centers face complex technical obstacles that need smart BIM implementation strategies. These challenges require a deep understanding of their scope to make BIM work in construction project management.

Rising Energy Demand in Data Centers & BIM Optimization

- Data center designers face their biggest challenge in meeting soaring electricity needs. US data centers use more than 4% of the country’s total electricity.

- This number could jump to about 9% by 2030. A large facility needs as much electricity as 50,000 homes. The capacity might triple by the end of this decade.

- The efficiency numbers paint a concerning picture. Each watt that powers IT equipment needs another watt for overhead systems.

- Only about 45% of data center power actually runs the IT load. BIM technologies are a great way to get better energy distribution models and optimization.

Cooling Challenges in Data Centers and BIM-Enabled Solutions

- Thermal management eats up about 38% of a typical data center’s energy budget. Advanced computing equipment, especially for AI workloads, needs more cooling power.

- AI-focused facilities’ server racks can hit power densities of over 120kW per rack. This creates massive heat that needs quick removal.

- Money matters too. Modern liquid cooling systems can cost $2,000 per kilowatt of cooled power.

- Enterprise cooling infrastructure often costs more than $100,000. These numbers make cooling optimization through precise BIM in MEP coordination valuable.

Space Optimization in High-Density Data Centers with BIM

- Data center designers always try to pack maximum computing power into the smallest space possible. Blade servers save lots of space but create hot spots that need special cooling solutions.

- Zero-U hardware installations mount equipment outside standard racks in central locations to free up valuable rack space.

- BIM helps model these complex spatial relationships. Containerization with platforms like Kubernetes boosts server usage and rack density. This gives better BIM support for facility management throughout its life.

BIM Utility Modeling and Coordination for Wet Utilities in Data Centers – explore our project case study to see how seamless coordination drives efficiency and precision.

How BIM Improves Data Center Design

BIM creates a digital framework that reshapes the scene of data center design, visualization, and coordination. This digital approach solves many complex challenges in these sophisticated facilities.

- 3D BIM Visualization for Data Center Architecture & MEP Systems

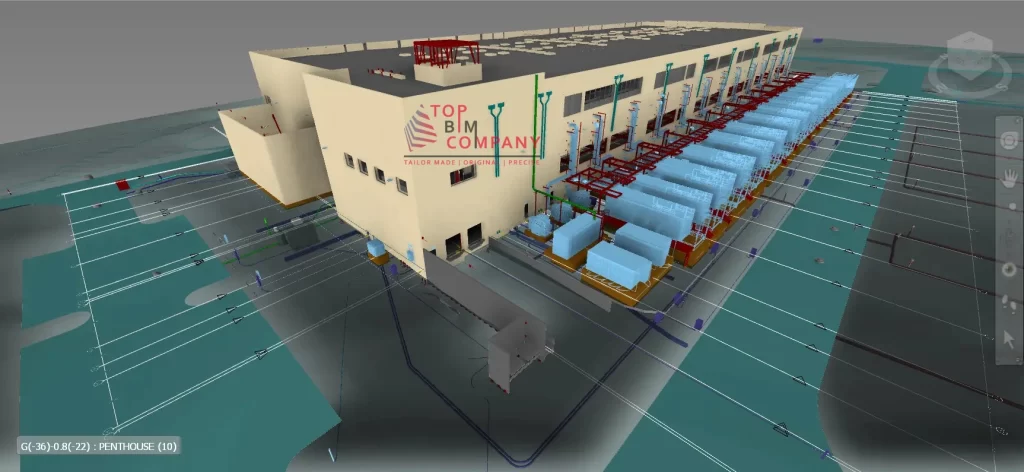

- BIM combines architectural, structural, and MEP systems into a single three-dimensional model that explains spatial relationships. Architects and engineers start by developing design intent drawings that outline simple layouts and system requirements.

- BIM specialists then create detailed, dimensionally accurate 3D models for each discipline. Teams can get into critical areas like cooling systems and power distribution with unprecedented clarity through this visualization level.

BIM simulations help stakeholders build virtual replicas to check spatial constraints, especially for dense MEP systems that compete for limited space in compact data center environments.

BIM Clash Detection for Data Center Design Efficiency

- BIM’s most valuable capability lets teams identify and resolve potential system conflicts before construction starts. Project teams use tools like Revit and Navisworks Clash Detective to create coordinated models that catch hundreds of conflicts early in design.

- These conflicts include ductwork crossing cable trays or piping conflicting with structural beams.

- Hard clashes happen when two components physically overlap, soft clashes involve clearance issues, and workflow clashes relate to scheduling conflicts. This proactive approach reduces cost, rework, and construction delays by a lot.

BIM-Driven MEP Integration in Data Centers

- Data centers feature exceptionally dense MEP systems that run side-by-side where ducts, conduits, pipes, and structural elements often compete for limited space.

- Teams use BIM to create detailed underfloor layouts that model all ducts, cabling trays, and power runs.

- The system supports precise coordination with structural elements such as pedestals to ensure zero spatial conflicts, which preserves airflow and structural integrity.

- Electrical engineers can transfer model data directly for advanced analysis, which enables load flow studies and ensures power systems remain balanced, reliable, and adaptable.

Future-proof your data center with sustainable, scalable, and efficient BIM strategies— Contact Our Experts

BIM for Energy Efficiency & Sustainable Data Center Design

Energy efficiency leads modern data center design challenges. BIM strategy implementation provides innovative solutions that reduce consumption and ensure peak performance.

6D BIM Energy Modeling for Sustainable Data Centers

6D BIM adds sustainability dimensions to data center planning beyond standard 3D modeling. Engineers can simulate facility performance under different conditions by integrating energy analysis into the design process. Design teams test multiple scenarios and compare outcomes to find the best solutions through detailed energy modeling.

6D BIM’s strength comes from its ability to predict outcomes. Designers can take proactive steps and:

- Study thermal behaviors across seasons

- Evaluate equipment energy profiles

- Test cooling system performance

BIM for Power Usage Effectiveness (PUE) Optimization in Data Centers

PUE measures the ratio between total facility power and IT equipment power, which remains the industry standard for data center efficiency. Digital models created through BIM technology help achieve precise PUE optimization by tracking all energy-consuming systems.

BIM in MEP coordination lets engineers test different cooling methods, airflow strategies, and power distribution setups during the design phase. Facility managers use these models to track performance against design targets, which helps maintain ideal PUE ratios throughout the building’s life.

Lifecycle Management of Data Centers Using BIM

BIM creates substantial value throughout a data center’s operational lifecycle after the construction phase ends. Building information management practices create, maintain, and use data to handle operations and maintenance activities. Facility managers can extract value from improved data quality.

Digital Twin Technology for Data Center Operations with BIM

Digital twins turn BIM models into living virtual replicas of data centers that connect with IoT sensors and building management systems to provide up-to-the-minute operational data. These advanced twins help predict maintenance needs, optimize performance, and test scenarios without risking live operations. Facility managers use digital twins to:

- Monitor power and cooling efficiency

- Simulate different operational scenarios

- Detect anomalies proactively

- Predict equipment failures before they occur

Digital twins combined with artificial intelligence and machine learning capabilities boost these models and help facility owners troubleshoot issues proactively. Data-driven decision making has become crucial for survival in today’s ever-changing data center environment.

BIM As-Built Models for Facility Management in Data Centers

The BIM As-Built Model becomes the authoritative source and reference for the building after construction. This model contains material and equipment properties determined during construction that form the foundation for facility management.

Construction details may be removed during this transition while preserving key data for long-term planning. The BIM FM Model connects to facility management systems that track work orders, maintenance operations, and equipment replacement costs. Facility managers can explore buildings virtually, find equipment quickly, and plan future upgrades with complete visibility into spatial constraints.

BIM bridges the gap between design, construction, and operation that boosts maintenance efficiency and reduces expensive downtime.

Real-World Applications of BIM in Data Centers

Leading data center companies have achieved remarkable results with their BIM strategy implementation. Major industry players now employ comprehensive BIM technologies that solve complex design and operational challenges.

- Microsoft’s cloud infrastructure team has reduced construction schedules by up to 30% in their hyperscale facilities through BIM coordination strategies.

- Their BIM implementation strategy enables prefabrication of complex mechanical systems off-site by establishing clear workflows and standardized templates.

- This minimizes the time needed for on-site installation.

- Google’s data center projects take a similar approach to construction project management with BIM.

- They focus on creating reusable component libraries within their BIM framework.

- This allows them to scale quickly while keeping consistency in their facilities worldwide.

- BIM-based facility management gives colocation providers significant advantages. Equinix’s maintenance response times improved by about 45% because their equipment documentation became more accessible. They combined their BIM models with work order management to create efficient operational workflows.

- Facebook (Meta) led the way in using BIM for MEP coordination in their data centers. They developed custom plugins to analyze cooling efficiency in their BIM environment. Their engineers can now simulate airflow patterns and spot potential hotspots before construction starts.

These examples share a common element – a well-considered BIM strategy that meets specific operational needs and builds frameworks for future growth.

Conclusion :

The future of data centers won’t be defined only by how much power they can supply or how many racks they can hold, it will be defined by how intelligently they are planned, built, and managed. BIM is not just a design tool; it is the connective tissue that links compliance, prefabrication, energy efficiency, and lifecycle operations into one cohesive strategy. By embracing BIM, stakeholders can move beyond reactive problem-solving toward proactive innovation, delivering facilities that are safer, faster to build, easier to scale, and more sustainable to operate. In an industry where downtime costs millions and growth waits for no one, BIM is not optional, it is the competitive edge that future-ready data centers cannot afford to ignore.

Frequently Asked Questions (FAQs):

FM teams, operations managers, IT infrastructure teams, and planners all benefit from BIM’s centralized and accessible information model.

BIM helps visualize space usage, plan expansions, manage cabling and cooling pathways, and reduce inefficiencies in layout and power distribution strategies.

Accurate data allows managers to predict failures, optimize maintenance schedules, and make informed decisions that protect uptime – a top priority for data centers.

BIM provides information on equipment specs, power and cooling distribution, maintenance history, spatial relationships, and system interdependencies for smarter management.

BIM centralizes asset information, floor layouts, and system performance data, enabling real-time insights into infrastructure health, capacity planning, and maintenance needs. This level of detail extends the value of data center management beyond design into operations.

Our Services

Latest Post

Get A Free Quote

BIM Construction is the Future

Building information modeling (BIM) is the future of building design and construction. Get in touch with our BIM Experts.