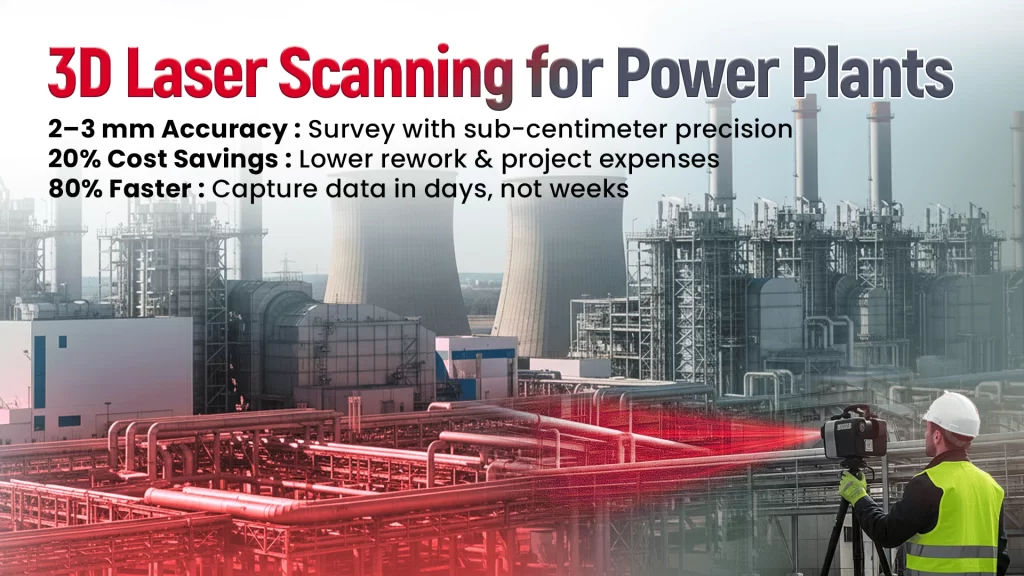

3D laser scanning delivers remarkable precision with sub-centimeter accuracy of 2-3 millimeters, transforming our ability to capture and document complex environments. This state-of-the-art system employs high-speed LiDAR that collects millions of measurement points. These points form a cloud that accurately represents the physical environment’s shape, size, and spatial relationships.

Table of Contents

TogglePower plant facilities rely heavily on 3D laser scanning to update their infrastructure with precise documentation. The technology’s exceptional precision proves invaluable to upgrade and maintain critical components like boilers, turbines, and complex piping systems. Industrial projects that implement 3D laser scanning can see cost reductions up to 20%. This makes it both technically advantageous and financially sound.

This piece explores the inner workings of 3D laser scanning, required equipment, and key applications that make it crucial for power generation facilities. You’ll discover everything about using this technology in power plants, whether you need to update your facility or create as-built documentation with 99.8% survey accuracy.

Step-by-Step Workflow for 3D Laser Scanning in Power Plants

Implementing 3D laser scanning in power plants requires a structured approach to ensure precision, safety, and efficiency. Below is the proven workflow followed by professional LiDAR scanning teams:

Site Assessment & Safety Planning

- The process begins with a comprehensive site assessment to define the scanning scope, technical requirements, and project timeline.

- Safety is the highest priority, proper authorizations must be secured, and scanning areas cleared of unnecessary personnel.

Field & Office Coordination

- Collaboration between field operators and office engineers ensures the scanning objectives are aligned.

- Clear requirements and data standards are established before mobilization, helping streamline processes and minimize rework.

Scanner Setup & Calibration

- Technicians position the laser scanner on stable ground and verify battery levels, storage capacity, and calibration settings.

- This preparation guarantees uninterrupted, high-accuracy data collection.

Target Placement for Accuracy

- Spherical or checkerboard targets are strategically placed at various elevations across the plant.

- Targets must avoid straight-line or repetitive patterns to maintain clear spatial definitions and accurate scan registration.

360° Laser Sweeps with Overlap

- Operators conduct 360-degree LiDAR sweeps at each station, ensuring at least 30% overlap between consecutive scans.

- This technique enables complete documentation of large plant sections in a single day, maintaining survey-grade accuracy (±1/4 inch at 100 meters).

Data Registration & Point Cloud Creation

- Once field scanning is complete, all datasets are registered and merged into a single, cohesive point cloud.

- This unified dataset becomes the foundation for as-built documentation, 2D CAD drawings, 3D BIM models, and immersive virtual walkthroughs, supporting informed decision-making throughout the facility lifecycle.

Tools & Technologies for Power Plant Scanning

Power plants need specialized scanning equipment that delivers exceptional precision and range. Top manufacturers build scanners specifically for industrial settings. Each scanner has unique advantages that make it perfect for power plant use.

- The Leica Scan Station P40’s performance stands out with 3D accuracy of 3.2mm at 50m and 5.9mm at 100m.

- This makes it perfect to capture detailed data from large plant components. The RTC360 system captures 2 million points every second. Teams can document entire facility sections in just one day with this speed.

- The captured data needs adaptable software solutions. FARO SCENE helps with scan registration and creates stunning 3D visualizations. Leica Cyclone turns point clouds into formats that engineers can use.

- Modern scanning goes beyond just hardware. These solutions come with interactive registration and hybrid registration techniques. The software platforms can work with data from any scanner type – static, mobile, airborne, and hand-held devices.

- Professional scanners work well in harsh industrial settings with temperatures from -20°C to +50°C. The latest scanning tech delivers accuracy levels of ±25 μm for components and ±1 mm over 25m for entire facilities. This reliability is vital for critical power generation infrastructure.

Applications in Power Generation Facilities

Power plants use 3D laser scanning to maintain operations without interruption. This technology creates a full picture of everything needed to plan onsite work.

3D laser scanning offers several significant applications in power generation:

- Asset Management: 3D models give you a complete view of the infrastructure and help you make decisions about maintenance schedules. These models capture every detail from structural steel to small components like lights, handrails, and bolt patterns.

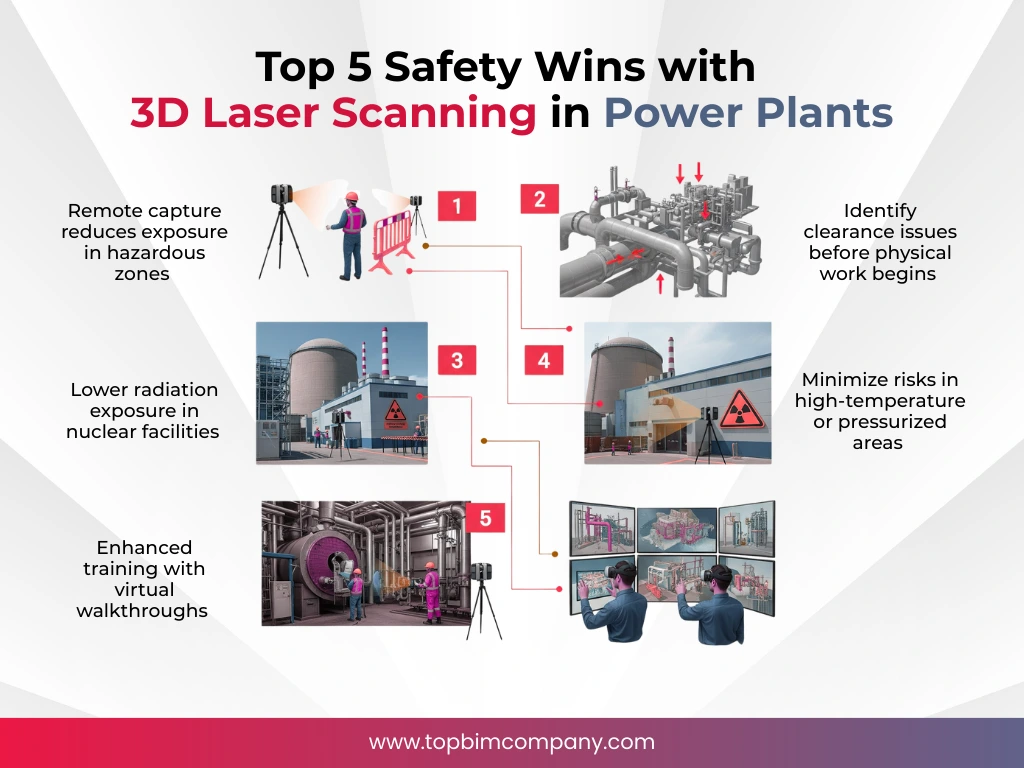

- Safety Enhancement: Teams can walk through dangerous areas virtually to lower exposure risks. Some facilities report their radiation exposure dropped nowhere near previous levels.

- Retrofitting & Upgrades: Engineers design complex updates that fit right the first time and avoid mistakes that get pricey. This method works great when older facilities need updates to meet new environmental standards.

- Virtual Collaboration: Teams take virtual tours of remote stations instead of expensive trips. This leads to better decisions and optimized operations.

The technology’s accuracy reaches less than a millimeter, which lets plant operators create detailed layouts for future changes. Power companies now have strong foundations for future 3D engineering, especially when you have thermal, hydro, and nuclear facilities that need to stay efficient and compliant.

Accuracy, Compliance & Safety Considerations

Safety and accuracy are the foundations of effective 3D laser scanning in power generation environments.

- Professional scanners achieve remarkable accuracy levels. They can measure within 3.2mm at 50m and 5.9mm at 100m. These precise measurements ensure reliable data for critical infrastructure components.

- This precision plays a crucial role in regulatory compliance. Power plant operators need complete documentation to show they meet spacing, clearance, and safety standards. Laser scanning provides one accurate source of truth that benefits multiple teams. Engineers use it for design work, safety teams plan hazard responses, and compliance teams maintain required documentation.

- The scanning technology gives you great safety advantages in hazardous environments. Teams can capture detailed as-built data from a safe distance when areas are restricted or unsafe. This approach eliminates unnecessary risks to personnel.

- Most industrial scanners qualify as Class 1 laser products under IEC 60825-1 standards. While this classification indicates relative safety, operators must follow proper protocols. These include appropriate training, equipment checks, and emergency procedures.

- Nuclear operators find accurate scanning data particularly valuable as a safeguard against delays, compliance risks, and safety issues. This technology helps teams spot hazards, clearance zones, and potential bottlenecks before workers face danger. The collected data stays reliable throughout the facility’s operational lifecycle.

Common Mistakes in Power Plant Scanning

Power plant operators who work with 3D laser scanning know about common pitfalls that can ruin scan quality or make entire projects useless.

- Poor site preparation leads to the most important problems. Operators who skip pre-scan surveys often deal with blocked views, miss key areas, or struggle with reflective surfaces.

- There’s another reason to be careful – wall coatings and insulation can be tricky. A wall in your scan might actually include 6″ of removable material, which creates false space limitations.

- Bad scanner placement can wreck your data. Scanner tripod legs might sink into hot asphalt during summer and slowly tilt, which ruins alignment data. Wrong technical settings can also create point clouds that are either too detailed or not detailed enough.

- Datasets get misaligned when operators don’t use enough control points. This creates “doubling” – a clear sign that your scan isn’t accurate.

- Power generation environments need special attention. Missing pipe misalignments can get pricey during redesigns. Scan teams sometimes overlook angular misalignments that skilled technicians need to spot through traditional methods.

- The problems continue in post-processing especially when you have skipped denoising steps and model conversion errors. These issues become worse with point cloud files that contain hundreds of millions of points.

Start building a sustainable future today. Get free 3D Laser Scanning consultation for your project.

Case Studies: Power Plant Scanning Projects in the U.S.

The advantages of 3D laser scanning in power generation facilities become clear when looking at real-world applications across the United States. From coal-fired plants to nuclear, hydroelectric, and gas-fired stations, scanning technology has delivered measurable results in accuracy, safety, and cost savings.

Coal-Fired Plant Retrofit (Midwestern U.S.)

A large Midwestern coal-fired power plant needed to install a new emissions control system inside a highly congested steel framework.

Traditional surveying methods would have taken weeks, delaying critical upgrades. With 3D laser scanning, engineers completed the survey in just a few days.

The scans revealed several potential clashes early in the design process, allowing the project team to avoid hundreds of thousands of dollars in rework costs while staying on schedule.

Nuclear Facility Upgrade

For a nuclear power station in the Southeast, downtime costs approached $1 million per day.

To minimize outages, the operator relied on high-accuracy laser scanning to document reactor areas, turbine halls, and piping systems before scheduled maintenance.

The data reduced the outage duration by 10%, ensured compliance with strict regulatory requirements, and safeguarded workers by reducing time spent in hazardous zones.

Hydroelectric Dam Modernization

One of the largest hydroelectric dams on the East Coast required upgrades to aging turbines and structural components.

Engineers used LiDAR-based scanning to map the massive internal spaces, including penstocks and powerhouse equipment.

The resulting as-built BIM models delivered precise measurements, improved worker safety during planning, and provided reliable data for long-term modernization efforts.

Gas-Fired Power Plant Expansion

A natural gas power station in the Southwest planned to expand capacity with new turbines and piping systems.

By employing 3D laser scanning, the project team captured existing infrastructure with millimeter-level accuracy, enabling exact prefabrication of components. This “right-first-time” approach cut the construction timeline by several weeks and reduced rework to less than 2% of the project scope.

Conclusion

The evidence from power generation facilities across the U.S. highlights how 3D laser scanning has shifted from an optional tool to a critical enabler of modernization. Its ability to deliver millimeter-level accuracy, rapid data collection, and safer on-site operations directly impacts the efficiency and reliability of power plants. By replacing weeks of manual surveying with days of precise scanning, facilities minimize costly rework, shorten outage schedules, and maintain compliance with evolving regulatory standards.

Beyond immediate cost and time savings, 3D laser scanning also establishes a digital foundation for long-term asset management, retrofitting, and digital twin integration. This creates smarter workflows for engineers, safer environments for workers, and stronger resilience for power companies facing increasing operational and environmental demands. Inference is clear: power plants that embrace laser scanning not only improve today’s performance but also secure tomorrow’s competitive edge.

Frequently Asked Questions (FAQs):

1. What is 3D laser scanning in power plants?

3D laser scanning uses LiDAR technology to capture millions of data points and create accurate 3D models of power plant facilities, improving documentation, safety, and upgrades.

2. Why do power plants use 3D laser scanning?

Power plants rely on 3D scanning for precise as-built documentation, retrofits, compliance, and safer project execution, reducing rework and downtime.

3. How accurate is 3D laser scanning for power plants?

Professional scanners achieve sub-centimeter accuracy, typically within 2–3 mm, ensuring reliable data for turbines, boilers, piping, and critical plant components.

4. What are the main benefits of 3D laser scanning in power generation?

Key benefits include 20% cost savings, 80% faster data collection, improved worker safety, accurate clash detection, and long-term asset management.

5. How does 3D laser scanning improve safety in power plants?

It reduces worker exposure in hazardous zones, supports remote inspections, minimizes radiation risks in nuclear plants, and allows virtual walkthroughs for training.

6. What is the workflow of 3D laser scanning in power plants?

The process includes site assessment, scanner setup, target placement, 360° sweeps, data registration, and point cloud creation for BIM models and documentation.

7. What tools and technologies are used for scanning power plants?

Top tools include Leica ScanStation P40, RTC360, FARO SCENE, and Leica Cyclone software for accurate scanning, data registration, and 3D visualizations.

8. Can 3D laser scanning reduce project downtime in power plants?

Yes. By providing accurate as-builts and enabling “right-first-time” designs, 3D scanning reduces delays, rework, and outage durations, saving significant costs.

9. What are common mistakes in power plant 3D laser scanning?

Mistakes include poor site preparation, incorrect scanner placement, insufficient control points, ignoring reflective surfaces, and errors in post-processing.

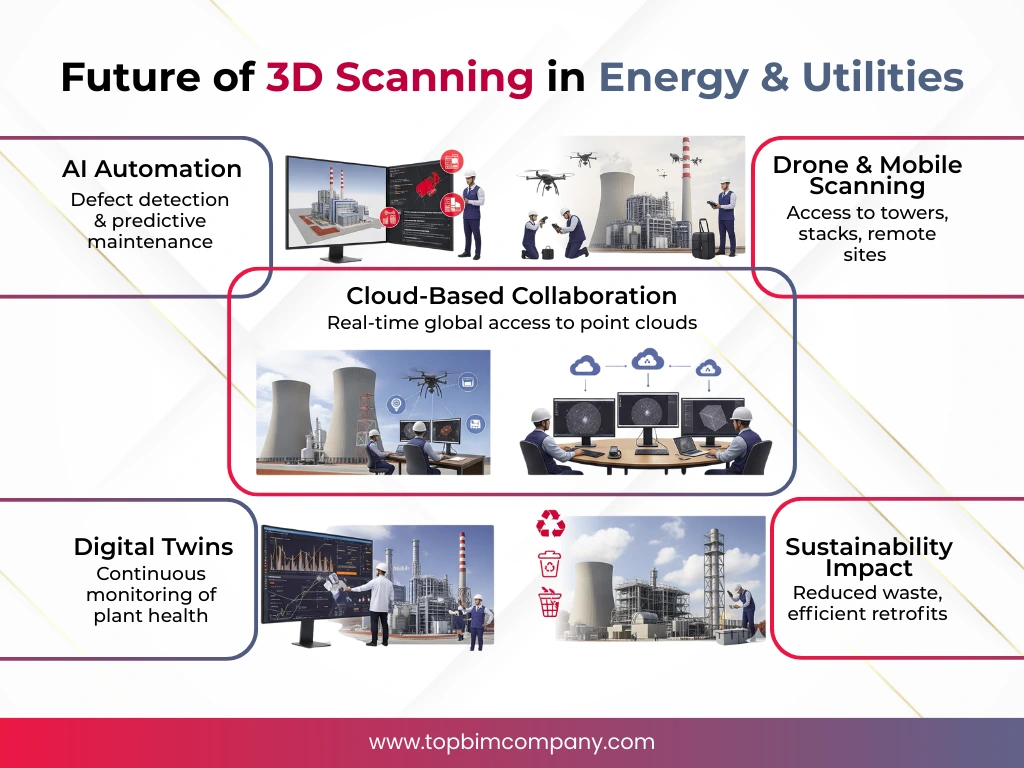

10. What is the future of 3D laser scanning in energy and utilities?

Future trends include AI-driven defect detection, drone-based scanning, cloud collaboration, digital twins for monitoring, and sustainability-focused retrofits.

Further Reading

How to Process Laser Scan Data and Select the Right Scanning Provider or Technology?

Ultimate Guide to 3D Laser Scanning & LiDAR Scanning

Comprehensive Guide on As-Built Surveys

How to Conduct 3D Laser Scanning in Data Centers and Choose the Right Tools?

How to Use As-Built Surveys in Renovation Projects and Avoid Common Mistakes?

How to Conduct an As-Built Survey and Choose the Right Tools for Your Project?

Our Services

Latest Post

Get A Free Quote

BIM Construction is the Future

Building information modeling (BIM) is the future of building design and construction. Get in touch with our BIM Experts.