3D laser scanning plays a vital role in oil and gas operations today. The technology delivers exact integrity assessments of pipelines by capturing every curve, joint, and intersection with unmatched precision. Engineers detect pipeline stress, corrosion, and mechanical damage without disrupting operations. Maintenance teams use scan data to plan their work and order replacement parts in the right sizes.

Table of Contents

TogglePrecision, Safety and Efficiency in High-Risk Environments

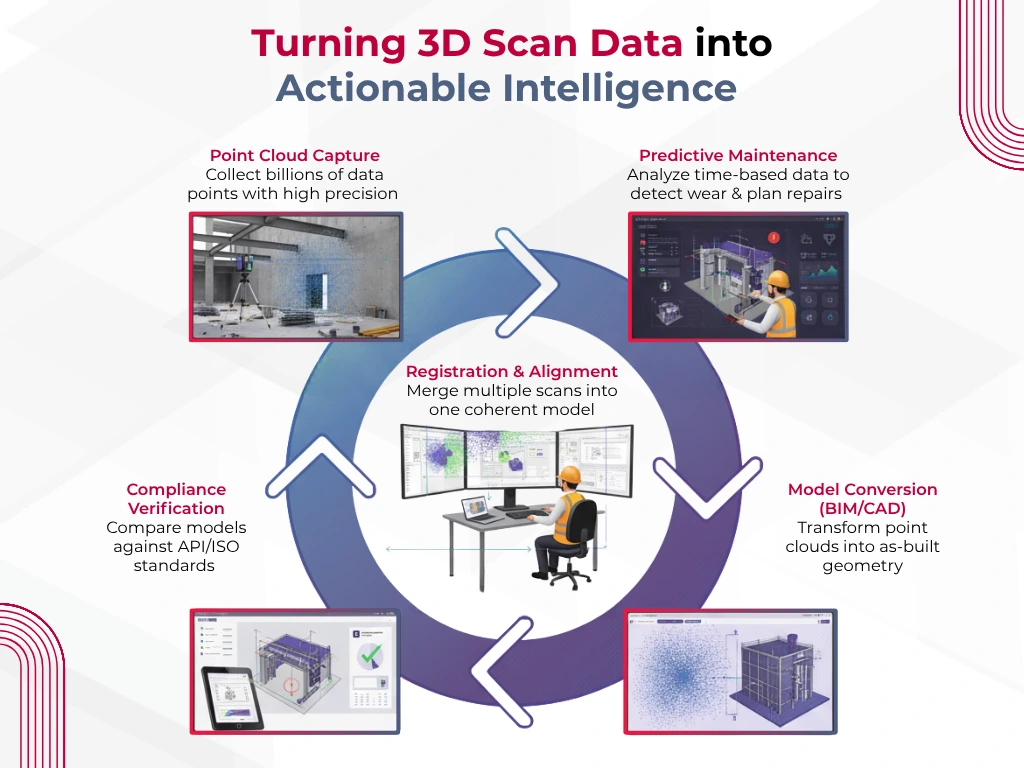

The scanning technology has changed traditional documentation in refineries. 3D scanning has also changed shutdown and turnaround planning completely.

ExxonMobil’s Baton Rouge refinery uses digital twins from laser scans that provide measurements down to tiny fractions of an inch. This precision lets them weld pipes into large units away from the site.

The results proved impressive at Joliet – turnaround time dropped by three weeks and on-site welding needs fell by 95%.

These applications reduce expensive field work, cut downtime, and improve safety based on real site conditions instead of estimates.

Ensuring Accuracy in Explosive & Hazardous Environments

Safety challenges in oil and gas environments demand specialized equipment to measure accurately.

- Modern industry uses intrinsically safe 3D laser scanners certified for explosive atmospheres that dramatically reduce worker exposure to hazardous conditions.

- The IMAGER 5006EX leads the way as the first ATEX-certified 3D scanning solution built specifically for high-risk environments. This scanner works safely in explosive atmospheres and holds certifications for both firedamp mines and explosive gas environments.

- The YHS12C(A) intrinsically safe scanner is like its counterpart, with “MA” certification and Ex iblMb explosion-proof marking that makes it perfect for hazardous mining environments.

- These specialized systems capture detailed data from up to 350 meters away. Workers don’t need to enter dangerous areas to take measurements. This remote capability reduces exposure to toxic gasses, extreme temperatures, and confined spaces that cause most workplace accidents in oil and gas operations.

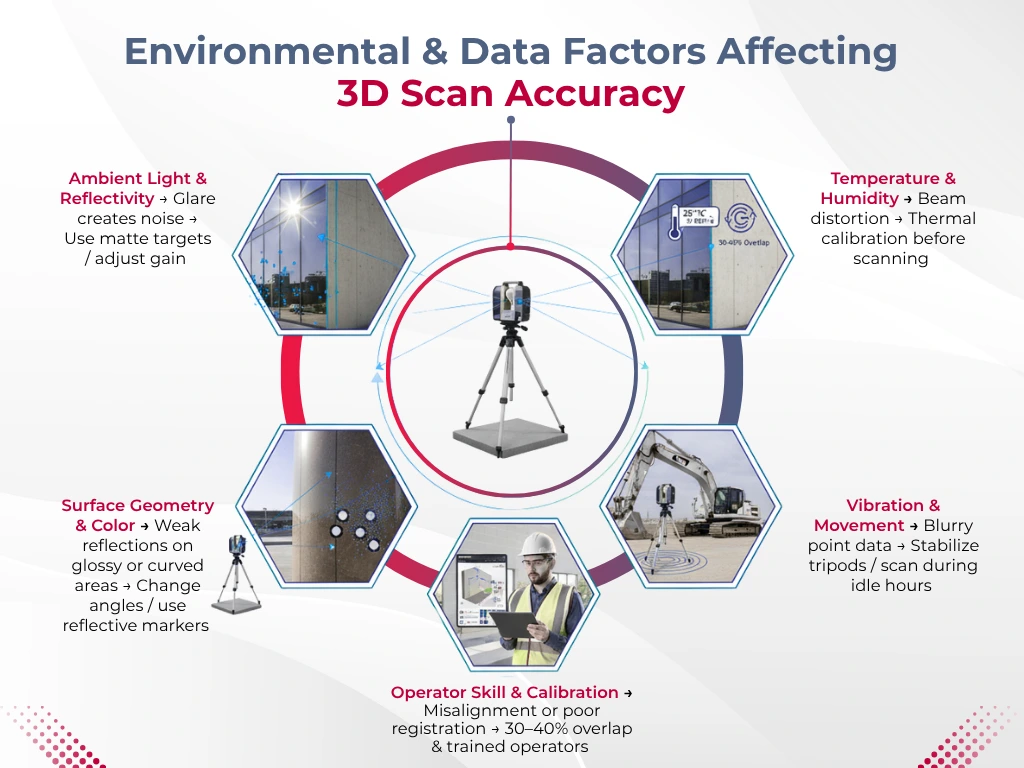

- Scan accuracy can change based on environmental conditions such as lighting, temperature, and humidity because these conditions might add noise to the data. In spite of that, modern SLAM scanners work exceptionally well in enclosed spaces.

- Root mean square deviations reach just 12-24 mm, which makes them perfect for documenting hazardous areas.

Companies can maintain millimeter-level precision with these advances without compromising safety protocols or shutting down facilities.

Meeting Compliance Standards (API, ISO, HSE Regulations)

Oil and gas operators must comply with strict regulations, and 3D scanning provides verified, timestamped documentation that aligns with major standards. These digital records serve as legally valid evidence during audits or inspections, reducing the risk of non-compliance penalties.

Standard / Code | Focus Area | Scanning Application |

API 650 / 653 | Tank inspection & evaluation | Compare scan data with API tolerances to identify non-conformance |

ISO 7507 | Tank calibration | Applicable to large tanks (> 3 m diameter), including floating roof systems |

ISO 10360-8 | Testing & verification | Defines consistency protocols for different scanners |

OSHA / MSHA / HSE | Worker safety standards | Enables remote measurement and documentation for audit evidence |

Avoiding Pitfalls- Common Errors in Oil & Gas Scanning Projects

Advanced technology hasn’t eliminated critical errors that plague 3D laser scanning projects in oil and gas environments.

- Poor scan planning leads to most project failures and creates incomplete data coverage that ruins model integrity.

- Point clouds don’t line up correctly when registration techniques are weak, which creates measurement errors.

- High temperatures, rain, and equipment vibrations nearby can damage data quality without proper control.

- Resolution settings create problems too. Many technicians use the same settings throughout facilities instead of adjusting them for different areas.

- Pipe racks need higher resolution than open spaces. Well-captured scans become useless when data management falls apart.

- Unstable equipment causes serious errors in the field. Tripods that sink even slightly during scanning create a “spiral effect” that prevents proper alignment. Proper training makes a huge difference in advanced 3D laser scanning equipment won’t work without operators who know what they’re doing.

Best Practice Checklist:

- 30–40% scan overlap

- Temperature & vibration control

- Customized resolution settings

- Skilled operator certification

Best Practices with Real-World Case Studies

Real-life success stories show how well-executed 3D laser scanning projects make a difference.

- Globe NV used this technology on the FPSO Girassol, the world’s largest Floating Production, Storage and Offloading vessel in Angola. The team achieved ±20mm accuracy by combining scan data from seventy different stations.

- F3 & Associates found a smart solution to document a California refinery. The team used three Leica HDS scanners at once and cut down the documentation time from six months to just one month. The team’s verdict was clear: “Without laser scanning, I’m not sure it would even be possible”.

- Chevron USA’s Gulf of Mexico platform upgrade turned out to be a big deal. The project eliminated 40-50 field welds, which saved about seven days of construction time. The team reduced shut-in time by 32 hours and avoided three field trips. These savings ended up being worth much more than what it cost to deploy the technology.

The most effective projects share key elements: solid planning, the right technology choices, good environmental conditions, and proper data checks. Companies that follow these practices see amazing results. Studies show that remote scanning cuts onsite worker hours by 60%. This makes 3D scanning a vital tool for forward-thinking oil and gas operators who face tighter regulations and smaller operational margins.

Start building a sustainable future today. Get free 3D Laser Scanning consultation for your project.

Cost & Risk Reduction Through Predictive Maintenance Models

3D laser scanning data is now integral to predictive maintenance models that identify wear, corrosion, or deformation before failure occurs. By comparing scans over time, operators can intervene early, extending asset life and minimizing downtime.

A refinery case study reported detecting a critical wear pattern in a compressor unit, preventing a potential shutdown. Such proactive insights lead to 25% reductions in project costs and timelines, along with lower labor expenses and improved budgeting accuracy.

Quantified Benefits of Predictive Maintenance with 3D Scanning

Metric | Traditional Maintenance | With 3D Scanning | Improvement |

Project Cost | 100% baseline | 75% | 25% cost reduction |

Downtime | High, reactive | Low, predictive | Up to 60% fewer on-site hours |

Equipment Lifespan | Shorter due to late detection | Extended by early intervention | + 20–30% |

Safety Exposure | Frequent field visits | Remote data capture | Major risk reduction |

Conclusion

The integration of 3D laser scanning in oil and gas operations clearly demonstrates that data precision directly drives operational resilience. The technology’s consistent ability to produce high-fidelity spatial information under hazardous and time-sensitive conditions infers a direct correlation between digital accuracy and project efficiency.

By replacing traditional manual inspections with intrinsically safe, ATEX-certified scanning systems, companies are not just improving measurement accuracy, they are actively redefining risk management frameworks. The evidence from real-world projects indicates that investment in 3D scanning leads to measurable performance gains: lower downtime, fewer safety incidents, and enhanced regulatory confidence.

Consequently, 3D laser scanning can be inferred as a strategic enabler rather than a supplementary tool. It supports predictive maintenance, strengthens compliance documentation, and establishes a digital foundation for future automation. As the oil and gas sector faces escalating safety and sustainability demands, the inference is clear, organizations that embed 3D laser scanning into their asset lifecycle management gain a competitive, operational, and safety advantage.

Frequently Asked Questions (FAQs):

1. What are the main applications of 3D laser scanning in the oil and gas industry?

3D laser scanning is widely used for pipeline integrity assessment, plant documentation, turnaround planning, and as-built modeling in oil and gas facilities. It helps engineers detect corrosion, deformation, and mechanical damage with millimeter-level accuracy—without interrupting operations.

2. How does 3D laser scanning improve safety in hazardous oil and gas environments?

Modern scanners like the IMAGER 5006EX and YHS12C(A) are ATEX-certified and intrinsically safe, meaning they can operate in explosive atmospheres without endangering workers. By capturing data remotely from up to 350 meters away, these devices minimize exposure to toxic gases, extreme temperatures, and confined spaces.

3. What are the key benefits of using 3D laser scanning for risk management in oil and gas projects?

3D laser scanning reduces project costs by up to 25% and cuts on-site hours by 60%. It supports predictive maintenance, prevents unplanned shutdowns, and enhances regulatory compliance by providing timestamped, verifiable digital records aligned with API, ISO, and HSE standards.

4. What factors can affect the accuracy of 3D laser scans in oil and gas environments?

Accuracy can be influenced by ambient light, temperature, humidity, vibration, and operator skill. To ensure reliable results, technicians must perform thermal calibration, maintain 30-40% scan overlap, use stabilized tripods, and adjust resolution settings according to the scanned environment.

5. How does 3D laser scanning contribute to predictive maintenance in refineries and offshore platforms?

By comparing periodic scan data, operators can identify wear or deformation early, preventing costly equipment failures. This predictive approach extends asset lifespan by 20-30%, reduces downtime, and enhances budgeting accuracy making 3D scanning an essential part of modern digital asset management.

Further Reading

Comprehensive Guide to 3D Laser Scanning for Oil & Gas

Ultimate Guide to 3D Laser Scanning & LiDAR Scanning

Comprehensive Guide on As-Built Surveys

How to Conduct 3D Laser Scanning in Data Centers and Choose the Right Tools?

Comprehensive Guide to 3D Laser Scanning for Power Plants

How to Use As-Built Surveys in Renovation Projects and Avoid Common Mistakes?

How to Conduct an As-Built Survey and Choose the Right Tools for Your Project?

Our Services

Latest Post

Get A Free Quote

BIM Construction is the Future

Building information modeling (BIM) is the future of building design and construction. Get in touch with our BIM Experts.