As-built surveys create an essential record of structures exactly as built, which ensures safety, compliance, and better operations. Making future modifications or checking project accountability would be nearly impossible without these crucial documentation tools. PPM has completed over 24,000 projects nationwide using these vital surveying methods.

Table of Contents

ToggleAn as-built survey captures a detailed record of all key components needed for accurate design work and long-term decisions. These surveys confirm that construction matches design plans -or document any changes made during the building process. Modern surveying equipment like laser scanners produces more accurate measurements than manual methods.

This piece will dive into the meaning and value of as-built surveys. You’ll learn the step-by-step process to conduct them, discover the tools and technologies used, and see their role in renovation projects. We’ll also explain how as-built drawings differ from record drawings, help you avoid common mistakes, and share best practices to use these vital surveys in your construction projects.

Step-by-Step Process for Conducting an As-Built Survey

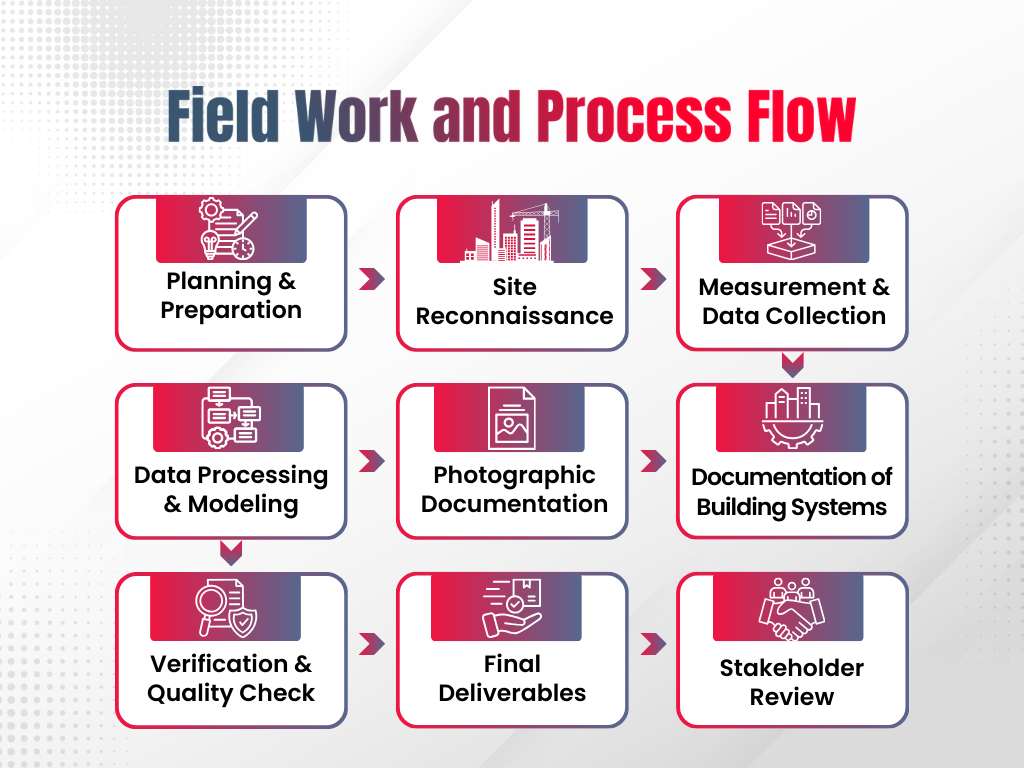

Conducting an as-built survey is not a single task but a structured workflow designed to transform on-site conditions into reliable project documentation. While the specific methods and tools may vary depending on project type and accuracy needs, most surveys follow a consistent path, from defining objectives to capturing site data, processing it into usable formats, and delivering verified records to stakeholders. Understanding this high-level process helps project teams see how each stage contributes to accuracy, compliance, and long-term asset management.

An as-built survey follows a predictable arc from planning to handover. At a high level, teams:

- Plan & Scope

Define why the survey is needed, the accuracy band, and what will be delivered (drawings/models/reports). - Capture Site Conditions

Visit the site to record existing conditions using fit-for-purpose tools. Establish reliable references for later validation. - Consolidate & Model

Organize field data and convert it into project-ready outputs (e.g., CAD/BIM) in agreed formats and naming standards. - Validate & Align

Reconcile the model/drawings with source data and design intent to confirm that deviations are correctly represented. - Handover & Review

Package approved deliverables and conduct a brief stakeholder review to confirm completeness and traceability.

Looking for the full workflow, field checklist, and step-by-step instructions?

Read the spoke: How to Conduct an As-Built Survey Step-by-Step

Start building a sustainable future today. Get free 3D Laser Scanning consultation for your project.

Tools and Technologies Used

Modern as-built surveys use specialized equipment to capture accurate structural data. The success of these surveys depends on choosing the right tools that match specific project needs.

Simple measurement tools work well for smaller projects. New technology has brought powerful options that deliver better precision and streamline processes. Surveyors choose their tools by looking at project size, accuracy needs, budget limits, and time constraints.

Tool | Description | Pros | Cons |

Tape Measure | Manual measuring device | Affordable, portable, no technical expertise needed | Limited range, potential for human error, time-consuming for large areas |

Laser Distance Meter | Electronic device using laser for measurements | Fast, accurate up to 1/16 inch, one-person operation | More expensive than tape measures, battery-dependent, limited to line-of-sight measurements |

Total Station | Optical instrument measuring angles and distances | High precision (±2mm), combines horizontal/vertical measurements, excellent for outdoor surveys | Expensive, requires skilled operator, setup time can be lengthy |

3D Laser Scanner | Creates point clouds via laser measurement | Captures millions of data points quickly, unmatched detail, reduces site time | High investment cost, complex data processing, large file sizes |

Photogrammetry | Creates 3D models from photographs | Budget-friendly, easy to use, minimal equipment needed | Less accurate than laser scanning, affected by lighting conditions |

Drones/UAVs | Aerial photography and data collection | Ideal for large areas, captures inaccessible locations, rapid deployment | Weather-dependent, requires permits, limited battery life |

Professional surveyors combine these tools with specialized software to turn raw measurements into useful as-built documentation. They use multiple technologies together to achieve the best accuracy and keep projects running efficiently.

Applying As-Built Surveys in Renovation Projects

Renovation projects just need accurate details about existing structures to avoid getting pricey mistakes. An as-built survey forms the foundation of any successful renovation project [123]. Teams risk facing unexpected challenges that can derail budgets and timelines without proper documentation.

Error prevention, project planning

The main advantage of using as-built documentation lies in preventing errors during renovations. These surveys spot potential obstacles early, especially when you have field conditions that differ from original plans. To cite an instance, teams can create new outlets by connecting to existing wiring instead of installing completely new systems when they know the exact location of utility lines.

The as-built surveys improve project planning by offering a complete picture of structural elements, mechanical systems, electrical layouts, plumbing networks, and architectural features. Architects and contractors can then:

- Create realistic renovation plans with minimal risk

- Spot conflicts with existing infrastructure

- Make smart decisions about changes needed

- Improve communication between all stakeholders

These surveys help plan facility maintenance by recording used materials and identifying utilities that might need attention. This knowledge leads to more accurate budgeting for future repairs or upgrades.

The surveys prove vital to show compliance with zoning authorities, get certificates of occupancy, and prove that all improvements meet local codes and regulations.

A precise snapshot of the building’s current state through an as-built survey helps renovation teams work efficiently while avoiding the surprises that often plague construction projects.

Understanding the Difference Between As-Built and Record Drawings

The construction industry uses “as-built drawings” and “record drawings” as if they mean the same thing. However, these documents have different purposes and require different professionals. A clear understanding of these terms helps everyone avoid confusion, legal issues, and unhappy clients.

Contractors create as-built drawings during construction. They show all the changes made on-site that differ from the original design plans. The team marks these changes in red ink on the original construction documents. These drawings show what the team actually built compared to the original design. The drawings can include changes that nobody has checked against building codes yet.

Architects or design professionals put together record drawings. They take the contractor’s as-built information and review it thoroughly. This review process makes record drawings much more reliable when managing and maintaining facilities later.

Comparison table between As-Built Drawings and Record Drawings:

Aspect | As-Built Drawings | Record Drawings |

Creator | Contractor | Architect/Design Professional |

Purpose | Document on-site changes | Provide official project documentation |

Process | Red-ink markups on original plans | Professional compilation of approved changes |

Reliability | May include unverified modifications | Professionally reviewed and approved |

Legal Status | May carry liability risks | More legally defensible |

Timing | Created during construction | Finalized after project completion |

Intended User | Construction team, facility managers | Owners, facility managers, future designers |

Verification Level | Minimal | Thorough professional review |

People often mix up or misunderstand these terms, even with clear industry standards. This confusion can cause problems with construction documentation and future renovation work.

Common Mistakes in As-Built Documentation

Project teams face various challenges while creating as-built documentation, no matter how careful they are. The documentation’s accuracy is vital to every surveying project, but several common issues can reduce how well it works.

- Incomplete or outdated documentation happens because teams don’t capture construction changes immediately. Site conditions or design tweaks often force field modifications that nobody records. This creates a gap between what’s built and what’s on paper.

- Rushed documentation is the biggest problem teams face. Project deadlines create pressure to finish quickly. This results in hurried as-built submissions without proper checks. The core team sometimes hands these significant documents to junior contractors who don’t have enough experience.

- Inadequate tools and methods continue to cause problems. Teams often use manual measurements that can lead to mistakes instead of modern digital documentation tools.

- Poor coordination creates confusion between site surveyors and drafting teams, particularly in complex projects. Without proper communication guidelines, information gets lost between field teams and office staff.

- Insufficient quality control lets mistakes slip through. Teams that skip review steps run into problems during design or construction.

These mistakes do more than just cause inconvenience. They can trigger failed inspections, design holdups, change orders, legal issues, and major construction delays.

Conclusion

The analysis of as-built surveys clearly shows that they are not just a documentation requirement but a strategic investment in project success. When executed with the right tools, ranging from laser scanning to drones, they transform construction workflows by minimizing errors, enhancing compliance, and creating a reliable foundation for renovations and facility management. The recurring issues of incomplete data, poor coordination, and rushed execution reinforce the need for methodical planning, quality control, and skilled surveyors. Ultimately, the inference is clear: organizations that prioritize accurate as-built documentation consistently achieve greater cost savings, faster project delivery, and long-term asset reliability, while those who neglect it risk legal disputes, failed inspections, and financial overruns.

Further Reading:

What is Laser Scanning in Surveying and How Can These Solutions Benefit Your Business?

BIM for Sustainability and Energy Efficiency Modeling

BIM for Heritage Preservation – Future of Protecting Our Past

Future-Proofing AEC Projects: The Role of BIM in Meeting Both ADA and OSHA Standards

Frequently Asked Questions (FAQs):

An as-built survey is a detailed record of a structure exactly as it was constructed, including all modifications made during the building process. It is important because it ensures compliance, safety, accurate documentation, and supports future renovations, facility management, and legal requirements.

As-built drawings are created by contractors during construction to mark on-site changes, while record drawings are compiled by architects or design professionals after reviewing and verifying as-built information. Record drawings are more reliable and legally defensible for long-term use.

Surveyors use a range of tools such as tape measures, laser distance meters, total stations, 3D laser scanners, photogrammetry, and drones. The choice depends on project size, accuracy requirements, and budget. Modern technologies like laser scanning and drones offer unmatched precision and efficiency.

Contractors usually record changes on-site, while professional surveyors and engineers capture precise measurements. Architects and design professionals may later use this information to prepare official record drawings for long-term use.

They provide a single source of truth for all stakeholders – contractors, architects, engineers, and facility managers. This reduces miscommunication, ensures alignment with project goals, and streamlines renovation or compliance approvals.

Skipping or rushing an as-built survey can lead to costly rework, safety hazards, failed inspections, legal disputes, and project delays. Accurate surveys help avoid these risks by ensuring complete and verifiable records.

Our Services

Latest Post

Get A Free Quote

BIM Construction is the Future

Building information modeling (BIM) is the future of building design and construction. Get in touch with our BIM Experts.