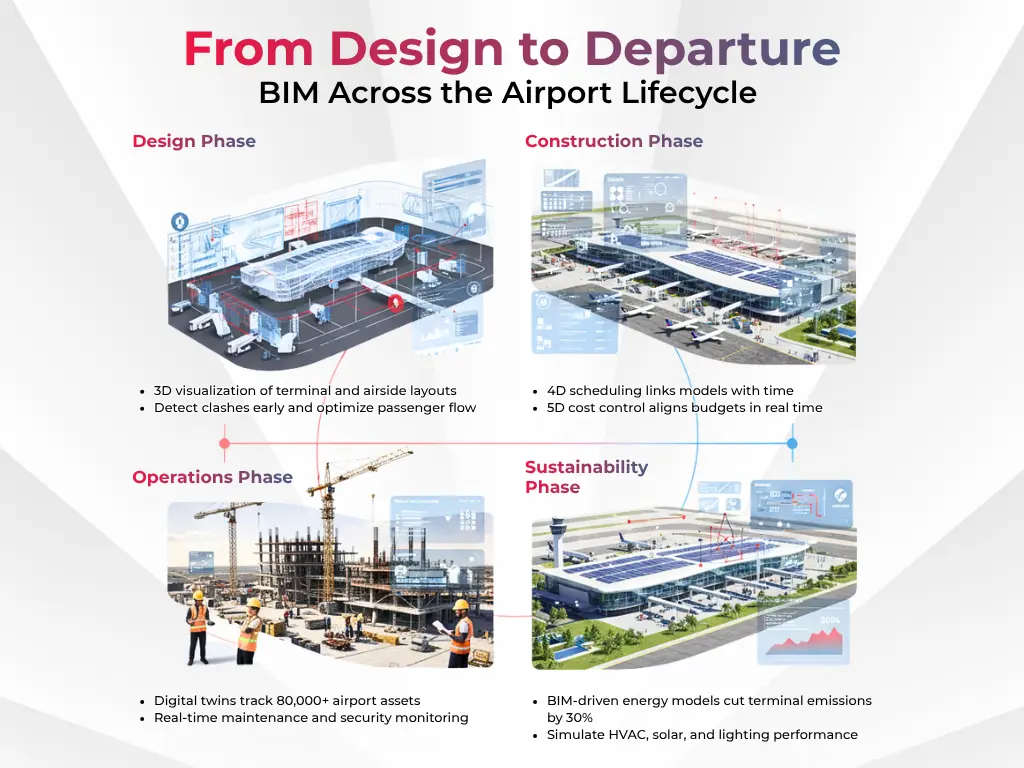

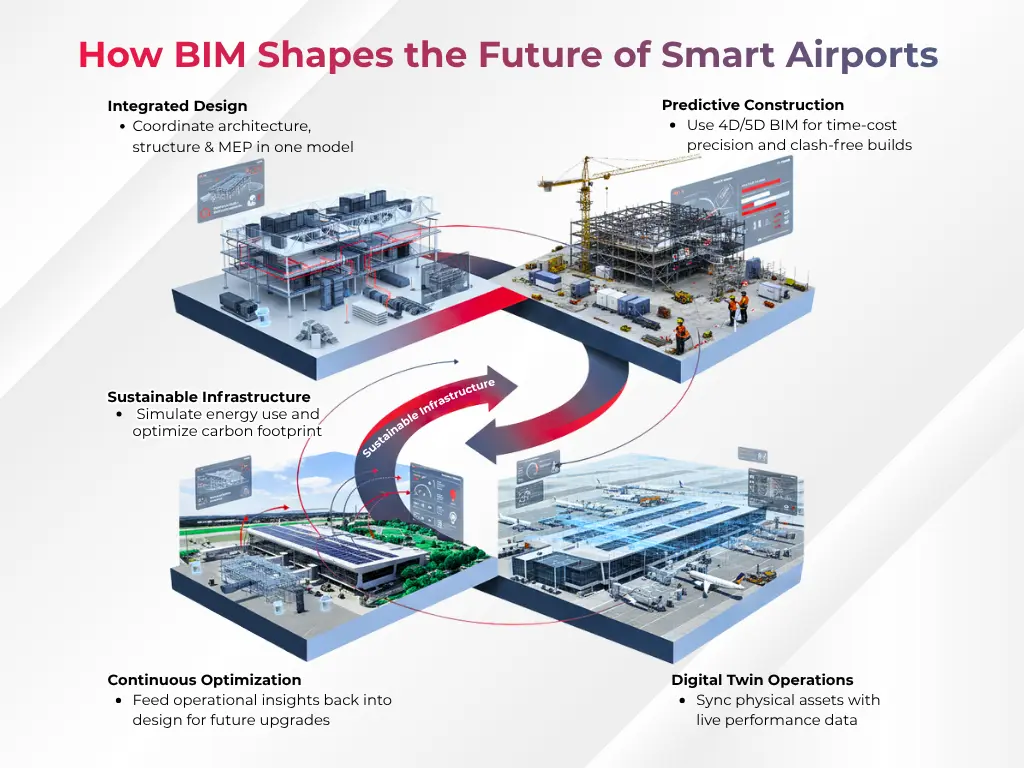

BIM serves as the life-blood of contemporary airport development, addressing the complexities of large-scale aviation projects through advanced tools and methodologies. This cutting-edge digital technology seamlessly integrates design, construction, and operational data throughout a project’s lifecycle. BIM for airports helps teams visualize designs in 3D before construction begins, enabling early identification of potential issues and saving both time and money.

Table of Contents

ToggleThe implementation of BIM delivers impressive results in airport construction and operations. For instance, Ezhou Airport in China reduced project investment by 10% through refined BIM technology management. The site selection process now takes just one month instead of six months, leading to more scientific and reasonable plans. BIM’s value extends beyond construction into operations, as exemplified by Amsterdam Airport Schiphol’s heavy reliance on digital twin concepts for safety and operational excellence. BIM-designed facilities can detect and log activity in restricted areas, enhancing overall security.

Let’s explore how airports benefit from BIM’s detailed coordination capabilities due to their large-scale and complex nature. BIM supports virtual simulation of airport construction processes, aids accurate cost estimation, and promotes eco-friendly design through advanced tools that simulate energy use and material efficiency.

Challenges in Airport Design & Construction

Modern airports stand among today’s most complex construction projects. These vast structures must serve millions of passengers each year while meeting strict requirements for safety, efficiency, and passenger comfort. The challenges in airport design and construction are multifaceted and require innovative solutions.

Category | Challenge | Description | Impact / Concern |

Passenger Flow | Managing traveler movement efficiently | Air travelers spend about 108 minutes in terminals, facing delays at check-in and security. | Bottlenecks reduce efficiency and comfort; requires balanced planning for seating, dining, and circulation. |

Safety & Regulatory Compliance | Meeting strict aviation safety and construction standards | Airports must adhere to regulations covering fire safety, emergencies, passenger screening, and structural protection. | Non-compliance risks safety and delays; needs coordinated planning, scheduling, and risk control during construction. |

Multi-System Integration | Synchronizing diverse automation and building systems | Airports operate dozens of systems (mechanical, electrical, security, communications) from different vendors with limited compatibility. | Disconnected systems cause data silos, slower decisions, and inefficient operations; requires unified BIM-driven integration. |

How BIM Supports Airport Design

BIM technology is transforming airport design by providing powerful tools that help deal with aviation facilities’ unique complexities. Airport planners can now use robust digital platforms to improve precision and efficiency throughout the design process.

- Spatial Planning

- BIM aids the integration of design disciplines to coordinate space within airport terminals. This approach reduces clashes and conflicts in terminal layouts while making the best use of available space.

- BIM makes it possible to map infrastructure systems precisely, including runways, terminals, and utilities, ensuring proper planning of all critical elements. In a recent 150,000 square feet airport terminal project, teams achieved clash-free BIM models using detailed coordination techniques.

- Discipline Coordination

- BIM creates a central platform where architects, engineers, and planners work together naturally. This integrated environment helps teams maintain designs that meet aviation standards while coordinating models between disciplines.

- One airport terminal project used Autodesk Revit for 3D BIM modeling and interference checks to spot clashes with other disciplines early in the design phase. BIM Collaborate Pro facilitated communication between teams working on the same platform, enhancing overall design coordination.

- Passenger Flow Simulations

- BIM lets designers simulate passenger movement within terminals to find potential bottlenecks. These simulations test different scenarios, especially during peak times with highest passenger volumes.

- A subway station study combined pedestrian simulation with BIM technology to improve flow lines through quantitative data analysis. The platform width calculations were based on projected long-term peak-hour unidirectional transfer flow of 12,000 people per hour, demonstrating the power of BIM in optimizing terminal capacity.

BIM in Airport Construction Phase

BIM’s practical use goes beyond design and into construction, transforming traditional building methods into model-based construction. This digital approach takes construction from drawing-based practices to detailed 3D digital model-based execution, creating a foundation to measure and manage projects with precision.

- 4D Scheduling

4D BIM adds time as a vital dimension to construction planning, connecting each building component to specific timeline activities.

- Project teams create time-animated simulations that show the planned construction sequence by blending construction schedules with 3D models. This approach enables teams to spot out-of-sequence work and identify coordination problems between trades early, optimizing project scheduling and construction sequencing.

- The Netherlands’ Schiphol Airport used 4D planning for runway maintenance, helping teams visualize different scenarios for runway, taxiway, and airstrip availability. The 4D BIM simulation serves as a key element during daily stands to address high-risk areas and plan activities, showcasing the power of BIM in airport pavement management.

- 5D Cost Control

5D BIM builds on 4D capabilities by adding cost data into models, enabling immediate budget monitoring throughout the project’s life.

- Design elements link directly to cost information, and stakeholders can track financial impacts as designs change, leading to significant cost savings.

- The Dallas/Fort Worth (DFW) International Airport expansion demonstrates 5D BIM’s value, saving millions in rework costs. The system’s model-linked quantity take-offs calculate quantities automatically when designs change, eliminating manual measuring and reducing human errors.

- 5D BIM creates a dynamic environment where financial data blends with building models, replacing static spreadsheets with smart, immediate cost management tools.

BIM for Airport Operations & Maintenance

BIM technology delivers value long after construction ends. The transition from construction to operations represents a key phase where BIM becomes a detailed management system, supporting the concept of smart airports.

- Digital Twins for Terminals and Runways

- Digital twin technology creates virtual replicas that match physical airport assets with up-to-the-minute data analysis. Amsterdam Airport Schiphol’s digital twin connects 80,000 assets into a common data environment (CDE), including runways, machines, and lighting systems.

- This integration helps predict maintenance needs and strengthens the airport’s reputation for reliability.

- San Francisco International Airport (SFO) uses a dynamic spatial system that combines BIM and Global Information Systems. The system optimizes maintenance and improves emergency response plans.

- These virtual models adjust operations based on passenger flows and open overflow security lanes when needed, showcasing the power of real-time data in airport management.

- Asset Lifecycle Management

- BIM acts as a valuable knowledge hub for facility management. The system connects to sensors on airport assets to track wear and tear, structural integrity, and damage.

- Facility managers can schedule maintenance at the right time to reduce costs and minimize downtime. Ezhou Airport in China has reduced project investment by 10% using this approach.

- BIM-powered asset management lets airports analyze energy use patterns for individual systems. This evidence-based method helps stakeholders make smart decisions that extend asset life while keeping operations efficient, contributing to overall energy efficiency in airport operations.

Start building a sustainable future today. Get free 3D Laser Scanning consultation for your project.

Sustainability in Airport Projects with BIM

BIM tools play a vital role in making airports more sustainable, helping reduce environmental impact throughout a facility’s lifespan.

- Energy-Efficient Systems

- Airport terminals consume huge amounts of energy, using more than 50% of an airport’s total energy, mostly for HVAC systems, lighting, interior power, and hot water. BIM design lets architects simulate energy performance accurately and test different scenarios before building starts.

- BIM’s value goes beyond the original design phase. Airport managers can track energy use patterns and spot ways to save energy. The tools help run smart temperature controls, energy-saving tech, and cooling methods that work with both environmental and operational needs, contributing to overall energy efficiency.

- Carbon Footprint Reduction

- Terminal buildings make up about 20% of aviation’s global emissions. While planes remain the biggest polluters, cutting terminal emissions is an affordable way to protect the environment. Research shows BIM projects can cut greenhouse gasses by 14-30% compared to regular methods over their lifespan.

- BIM makes carbon reduction better by working with Geographic Information Systems to tackle climate change effects. Airports can map areas at risk of flooding, build better stormwater systems, and set up pollution monitoring. BIM also helps airports obtain green building certifications like LEED by tracking detailed records and performance data that prove compliance.

Case Applications – BIM in American Airport Projects

American airports have seen great results from using BIM technology. The Orlando International Airport underwent a USD 3.1 billion expansion that used BIM throughout the project. Their Intermodal Terminal Facility (ITF), spanning 1.3 million square feet, used BIM technology to coordinate complex MEP systems in challenging spots like shear walls, showcasing effective MEP coordination.

- The Dallas/Fort Worth (DFW) International Airport expansion demonstrated how 5D BIM saved millions by spotting and fixing potential issues before building began. The team managed to keep their two-year schedule while handling complex multi-level structures and MEP systems, highlighting the benefits of clash detection in airport construction.

- The Oakland International Airport team built an 8,300-square-foot utility plant housing complex electrical, heating, ventilation, and air conditioning systems. They used software like Autodesk BIM 360 Glue and Navisworks to improve field visualization and simplify processes, demonstrating the power of collaborative tools in airport projects.

- BIM proved its worth at the New Orleans International Airport project by preventing clashes in two major buildings, a three-floor terminal with five zones and a two-floor concourse with six zones. The BIM models helped with 3D coordination and provided quantity take-offs and 4D scheduling features, optimizing the construction process.

- More success stories include JFK Terminal 5, LAX Tom Bradley Terminal, and Chicago O’Hare’s modernization program. These projects show how BIM improves coordination in airport construction, reduces rework, and optimizes operations, showcasing the benefits of BIM services in airport development.

Conclusion:

BIM is no longer just a design technology, it is the strategic core of aviation infrastructure intelligence. Airports that once relied on static blueprints now operate through living digital ecosystems where every beam, sensor, and passenger movement is connected through data.

The real transformation lies in how BIM reshapes decision-making, from reactive construction management to predictive, performance-based planning. With digital twins and integrated data models, airports can anticipate maintenance, optimize passenger flow, and minimize energy waste before problems surface.

As aviation hubs evolve into smart, self-regulating environments, BIM becomes the bridge between sustainability and scalability. It enables airports to grow responsibly, balancing expansion with environmental accountability, operational safety, and traveler comfort.

The airports leading this transformation prove that precision, integration, and foresight define tomorrow’s aviation success. In this new era, BIM is not a tool but a catalyst of intelligent airport ecosystems, where design, construction, and operations converge into one continuous, data-driven flight path toward the future.

Frequently Asked Questions (FAQs):

1. What is BIM in airport construction?

BIM (Building Information Modeling) in airport construction is a digital approach that integrates design, construction, and operational data into one intelligent 3D model. It helps architects, engineers, and airport authorities visualize, plan, and manage complex aviation projects efficiently from concept to operation.

2. How does BIM improve airport design and planning?

BIM enhances airport design through 3D visualization, clash detection, and spatial coordination. It helps planners simulate passenger flow, optimize terminal layouts, and ensure that structural, electrical, and mechanical systems work seamlessly together – leading to faster approvals and error-free designs.

3. What are the benefits of using BIM in airport construction projects?

BIM brings several benefits, including cost reduction (up to 10%), improved design accuracy, real-time project tracking, and reduced rework. It allows construction teams to use 4D and 5D BIM for time and cost control, ensuring better scheduling, budgeting, and on-site coordination.

4. How is BIM used in airport operations and maintenance?

After construction, BIM continues to support airport operations through digital twins-virtual models that monitor real-time asset performance. Airports like Schiphol and SFO use BIM to track 80,000+ assets, predict maintenance needs, enhance safety, and optimize passenger experiences.

5. Can BIM help airports become more sustainable?

Yes. BIM plays a vital role in sustainability by simulating energy use, improving HVAC efficiency, and cutting terminal emissions by up to 30%. It helps design energy-efficient systems, reduce carbon footprints, and supports certifications like LEED through accurate performance tracking.

6. What are some real-world examples of BIM in airport projects?

Leading airports such as Dallas/Fort Worth (DFW), Orlando International, Amsterdam Schiphol, and New Orleans International have successfully implemented BIM for design coordination, 4D/5D scheduling, and asset management-resulting in major cost and time savings.

7. Why should airports adopt BIM technology now?

Adopting BIM ensures airports stay future-ready. It connects design, construction, and operations through data-driven insights, improving safety, sustainability, and scalability. As aviation moves toward smart, self-regulating systems, BIM becomes essential for building intelligent airport ecosystems.

Further Reading

Comprehensive Guide to 3D Laser Scanning for Oil & Gas

Ultimate Guide to 3D Laser Scanning & LiDAR Scanning

Comprehensive Guide on As-Built Surveys

How to Conduct 3D Laser Scanning in Data Centers and Choose the Right Tools?

Comprehensive Guide to 3D Laser Scanning for Power Plants

How to Use As-Built Surveys in Renovation Projects and Avoid Common Mistakes?

Our Services

Latest Post

Get A Free Quote

BIM Construction is the Future

Building information modeling (BIM) is the future of building design and construction. Get in touch with our BIM Experts.