Digital twins go beyond simple 3D models. They serve as living digital counterparts that constantly update based on operational data. Digital twin in power plants integrates data from multiple sources to create a unified, real-time representation of the facility. Sensors, historical performance records, and detailed equipment specifications come together to create a complete virtual copy of the facility.

Table of Contents

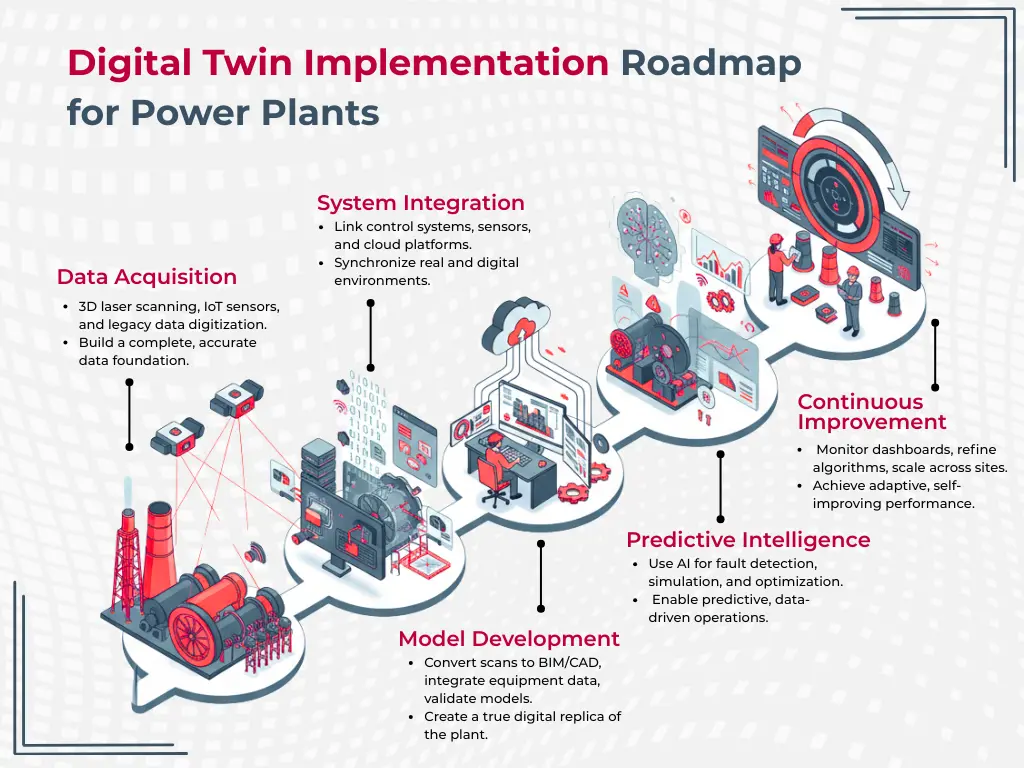

TogglePower plants need a well-laid-out process to implement digital twins. The foundation starts with complete data collection. The next step involves creating accurate models that turn physical features into digital form. The final phase connects operational systems to sync the physical plant with its digital twin in real time.

Digital twins bring unique value to power generation facilities. They help predict maintenance needs by spotting potential failures early. Plant operators can test different scenarios and check design changes virtually without disrupting actual operations. This capability lets them optimize efficiency without any risk to running operations.

Some challenges still exist. Older power plants struggle with data integration in their legacy systems. Building accurate models needs experts who understand both power generation and digital modeling. Yet the benefits usually make up for these implementation challenges.

Success with digital twins depends on clear goals from the start. The project needs support from everyone involved. A phased approach works better than trying to change everything at once. Strong data management rules ensure the digital twin gets accurate and consistent information.

Digital twins have grown from basic models into dynamic systems that provide useful insights. Power plant operators can now move from fixing problems to preventing them. This marks a fundamental change in managing these critical infrastructure assets.

How 3D Laser Scanning Provides Accurate Data for Digital Twins

The creation of accurate digital twins starts with precise data collection. 3D laser scanning is the life-blood technology that powers this crucial first step. This technology forms the foundations for 78% of facility-based digital twins in power plants and infrastructure.

- 3D laser scanning makes use of LiDAR (Light Detection and Ranging) technology. It captures millions of precise data points and creates detailed point clouds. These clouds represent the exact geometry of power plant environments. The process, known as “reality capture,” turns physical spaces into digital form with remarkable precision.

- Professional-grade scanners in power plants deliver extraordinary accuracy levels. They measure within 3.2mm at 50m and 5.9mm at 100m. Such precise measurements will give a reliable data set for critical infrastructure components. The accuracy directly affects safety and regulatory compliance.

- Point clouds offer capabilities beyond basic visualization. Teams can measure floor-to-ceiling heights, door openings, and any vertical or horizontal point-to-point distances. These measurements help maintain equipment’s design intent and performance throughout its lifecycle.

- The real magic happens when point clouds become functioning digital twins through data layer integration. Marcus Rodriguez from Autodesk explains, “The scanning process is just the beginning. What transforms a point cloud into a true digital twin is the integration of real-time data collection systems, historical information, and predictive analytics”.

- This unified dataset creates the foundations for complete as-built documentation, 2D CAD drawings, 3D BIM models, and immersive virtual walkthroughs. The implementation process becomes faster, with studies showing schedule compression of up to 10% with 3D laser scanning.

- Safety advantages in hazardous power plant environments are substantial. Teams can capture detailed as-built data safely from a distance in restricted or unsafe areas. This method eliminates unnecessary risks to personnel while providing complete documentation.

Scan data creates a permanent digital record that teams can share, store for future reference, and integrate with software platforms. Yes, it is this digital documentation that keeps accurate as-built information available throughout the facility’s operational lifecycle. This supports informed decision-making at every stage.

Simulating Plant Operations and Performance Virtually

Virtual simulation is reshaping the way power plants are managed. What once required risky, real-world trials can now be safely recreated in a digital environment. These simulations transform static 3D models into living operational tools, allowing operators to mirror real plant behaviors in real time.

Instead of halting production or running trial-and-error experiments on actual assets, plant teams can now:

- Test different operating scenarios virtually.

- Train operators for normal and abnormal conditions.

- Predict potential failures before they occur.

- Optimize turbine and generator performance for lower fuel use and reduced emissions.

By merging design data, control system inputs, and historical records into a unified platform, digital twins provide simulation fidelity that matches real-world complexity. This ensures decisions are backed by accurate, predictive insights rather than guesswork.

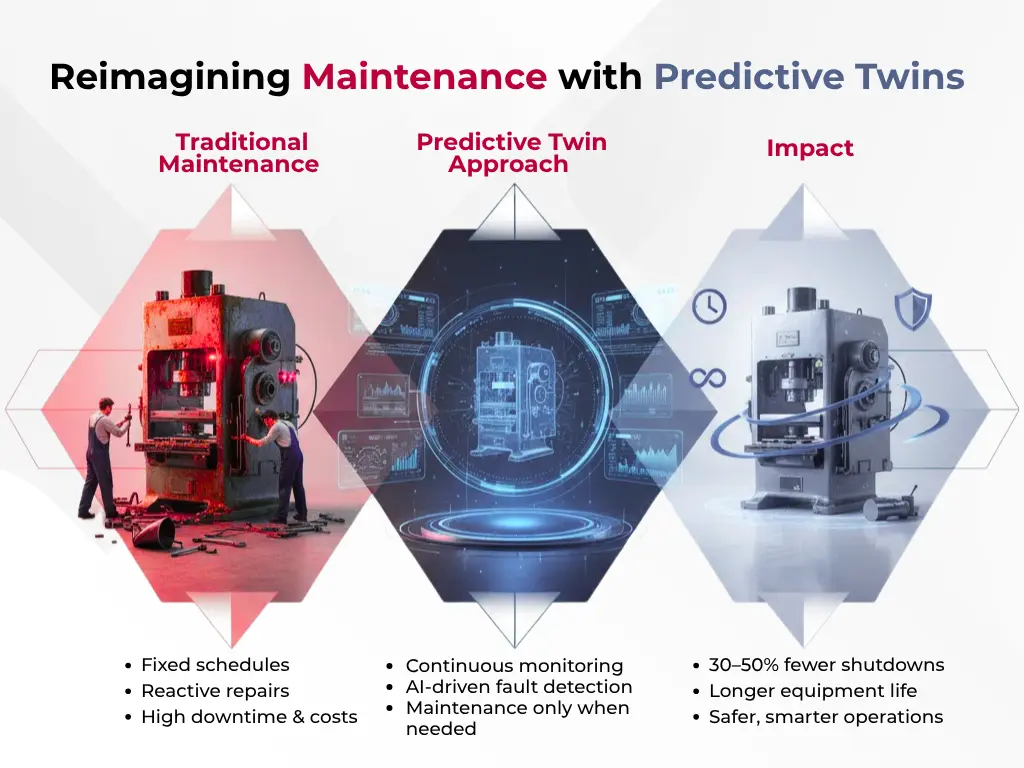

Traditional vs Digital Twin Simulation in Power Plants

Aspect | Traditional Approach | With Digital Twin Simulation |

Testing & Training | Risky, done on live systems | Safe virtual testing and operator training in a replica model |

Scenario Handling | Limited, time-consuming | Abnormal situations recreated quickly for faster learning |

Operational Adjustments | Slow, reactive changes | Real-time simulation enables quick efficiency improvements |

Maintenance | Reactive or schedule-based | Predictive, with failures forecasted before breakdowns |

Operational Safety | Requires physical presence in risky areas | Remote, automated workflows during outages/startups |

Performance Optimization | Trial-and-error in real operations | Simulations optimize turbines, generators & fuel consumption |

Digital twin simulations mark a shift from reaction to prediction in power plant operations. By recreating both routine and abnormal scenarios virtually, operators can achieve:

- Higher workforce competency through immersive training.

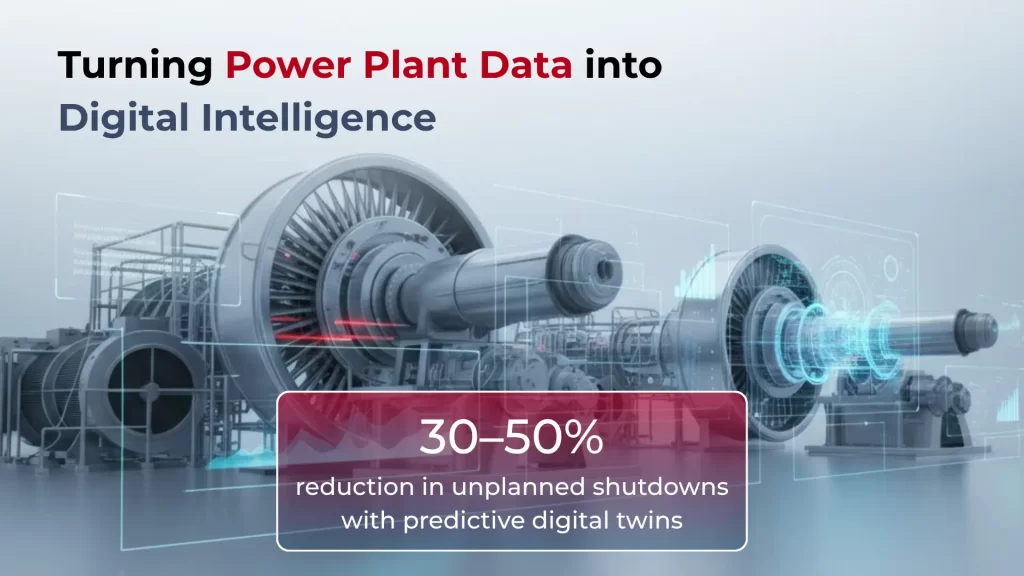

- Smarter maintenance strategies that cut unplanned downtime by 30–50%.

- Improved environmental performance through fuel and emission optimization.

- Better financial outcomes, reducing operational costs by millions annually.

Looking ahead, as artificial intelligence and physics-informed neural networks become more deeply integrated into digital twins, simulations will evolve from being decision-support tools to decision-automation systems. This transition will not only drive profitability but also build resilience and sustainability into the very core of power plant management.

Optimizing Operational Decisions Using Digital Twin Insights

Digital twins give power plant teams informed ways to make decisions based on exact information instead of guesswork. These virtual replicas analyze up-to-the-minute data and provide practical knowledge that affects both operations and financial results.

Digital twins bring substantial economic advantages when used to optimize decisions. These solutions can cut yearly operational and maintenance costs by at least USD 60 million. They also reduce coal consumption costs by about a million dollars each year. The Yeongheung coal power plant in South Korea found and fixed 144 unusual events over 2.5 years, which saved USD 6 million in operations and maintenance costs.

Digital twin technology helps operators make smarter choices using accurate, current data. Operators can spot inefficiencies and find ways to improve multiple systems by running simulations and checking performance metrics. This informed strategy leaves less room for guesswork and reduces human mistakes in crucial decisions.

The optimization capabilities span several operational areas:

- Performance boost: Digital twins boost thermal efficiency by 0.4-0.6% in combined cycle power plants and achieve 2-5% efficiency improvements in load dispatch optimization

- Maintenance optimization: Predictive maintenance and fault detection cut unplanned shutdowns by 30-50% and lead to a 29% year-on-year improvement in forced outage rates

- Risk management: Operators can test systems under stress to find possible bottlenecks and try different operational protocols without physical risks

AI algorithms continuously analyze data flowing from physical plants to their virtual twins. AI learns normal operational patterns and spots subtle problems that human operators might miss. These early warnings help change maintenance from schedule-based to predictive strategies that extend equipment life and stop catastrophic breakdowns.

Physics-informed neural networks (PINNs) represent a major step forward. They add physical laws to the learning process and improve accuracy in complex modeling scenarios.

Start building a sustainable future today. Get free 3D Laser Scanning consultation for your project.

Use Cases of 3D Scan-Based Digital Twins in Power Plants

Power plants worldwide have adopted 3D scan-based digital twins with soaring wins. These real-life implementations prove the practical value of digital twin technology beyond theoretical benefits.

The implementation process starts with detailed laser scanning of existing facilities. Critical areas like turbine halls, boiler sections, and control rooms become the focus of original scanning. Teams can manage the digital twin implementation process and continue regular operations through this phased approach.

Successful case studies consistently show three key elements.

- Clear objectives must exist before implementation starts. The core team needs involvement throughout the process to ensure the digital twin meets practical needs. Data governance protocols should remain strong to keep the twin’s accuracy over time.

- Data integration with legacy systems, staff training needs, and initial cost concerns create common implementation hurdles.

- Notwithstanding that, facilities consistently show positive ROI through reduced maintenance costs, optimized operations, and longer equipment lifecycles.

Successful implementations deliver these main outcomes:

- Shorter maintenance cycles through better planning and visualization

- Better safety through fewer physical inspections

- Cooperative work between engineering, operations, and maintenance teams

Power plants that follow digital twin implementation best practices achieve faster adoption rates. Their time-to-value becomes shorter compared to facilities that attempt implementation without proven methods.

Conclusion

The experiences of power plants worldwide highlight a clear trend: 3D scan-based digital twins consistently transform operational challenges into opportunities for improvement. Facilities that begin with laser scanning and build structured digital twin frameworks gain the ability to simulate, predict, and optimize with accuracy that traditional methods cannot match.

These use cases suggest that success is not accidental, it depends on well-defined goals, continuous involvement from core teams, and strong data governance to keep digital replicas reliable over time. When implemented effectively, digital twins lead to measurable returns such as shorter maintenance cycles, improved safety, lower operating costs, and extended asset lifecycles.

More importantly, they shift the role of power plants from reactive maintenance and fragmented data handling to proactive management and integrated decision-making. This evolution makes digital twins not just a technological upgrade, but a strategic transformation tool shaping the future of sustainable and resilient power generation.

Frequently Asked Questions (FAQs):

1. What is a digital twin in the context of power plants?

A digital twin is a dynamic digital replica of a physical power plant that updates in real time using operational data. It combines 3D models, sensor inputs, and historical performance records to simulate, monitor, and optimize plant operations virtually.

2. How does 3D laser scanning contribute to creating digital twins?

3D laser scanning uses LiDAR technology to capture millions of data points that form accurate point clouds. These scans precisely represent plant structures, forming the foundation for 3D BIM models and digital twins. This ensures high accuracy, reduces safety risks, and accelerates project timelines by up to 10%.

3. What are the main benefits of implementing digital twins in power plants?

Digital twins enable predictive maintenance, reduce unplanned shutdowns by 30–50%, and improve operational efficiency. They allow operators to simulate scenarios, optimize energy use, extend equipment life, and enhance safety through remote inspections and training simulations.

4. What challenges do power plants face during digital twin implementation?

Common challenges include integrating data from legacy systems, ensuring data accuracy, training personnel, and managing upfront costs. Overcoming these requires clear objectives, team collaboration, strong data governance, and a phased rollout approach.

5. How do digital twins enhance decision-making and cost optimization?

By providing real-time analytics and predictive insights, digital twins help identify inefficiencies, forecast maintenance needs, and optimize operations. Some power plants have reported saving over USD 60 million annually through better performance monitoring and predictive maintenance.

Further Reading

Comprehensive Guide to 3D Laser Scanning for Oil & Gas

Ultimate Guide to 3D Laser Scanning & LiDAR Scanning

Comprehensive Guide on As-Built Surveys

How to Conduct 3D Laser Scanning in Data Centers and Choose the Right Tools?

Comprehensive Guide to 3D Laser Scanning for Power Plants

How to Use As-Built Surveys in Renovation Projects and Avoid Common Mistakes?

How to Conduct an As-Built Survey and Choose the Right Tools for Your Project?

Our Services

Latest Post

Get A Free Quote

BIM Construction is the Future

Building information modeling (BIM) is the future of building design and construction. Get in touch with our BIM Experts.