Factories must modernize to stay competitive in today’s industrial world.

Table of Contents

ToggleResearch shows smart factory initiatives can boost output, utilization, and productivity by 10-12%. Yet only 39% of frontline manufacturing workers call their facilities “very modern”.

This gap shows both challenges and opportunities ahead.

Market changes and higher expectations drive the need for new technology. Research reveals that 86% of manufacturing leaders see smart factory initiatives as their main competitive advantage in the next five years. The “Amazon Effect” has also pushed manufacturing operations to optimize their efficiency like never before.

Eco-friendly practices play a crucial role in modernization plans. While 55% of workers want greener working conditions, only 45% believe their companies make this a priority. Smart companies know that technology helps track sustainability metrics better – from cutting waste to optimizing energy use.

Today’s manufacturing facilities must meet stricter environmental standards worldwide. The EPA collected USD 1.05 billion in civil penalties for environmental compliance violations in 2021 alone. American and British consumers take notice too – over 70% change their buying choices based on a company’s environmental values.

Factories can meet both modernization needs and sustainability goals by using technologies like 3D laser scanning. This creates a path toward operational excellence that supports environmental responsibility.

Retrofitting Legacy Facilities with 3D Laser Scanning

Old manufacturing plants face modernization challenges due to decades of changes with poor records. Many operate using missing or outdated blueprints that don’t match current conditions.

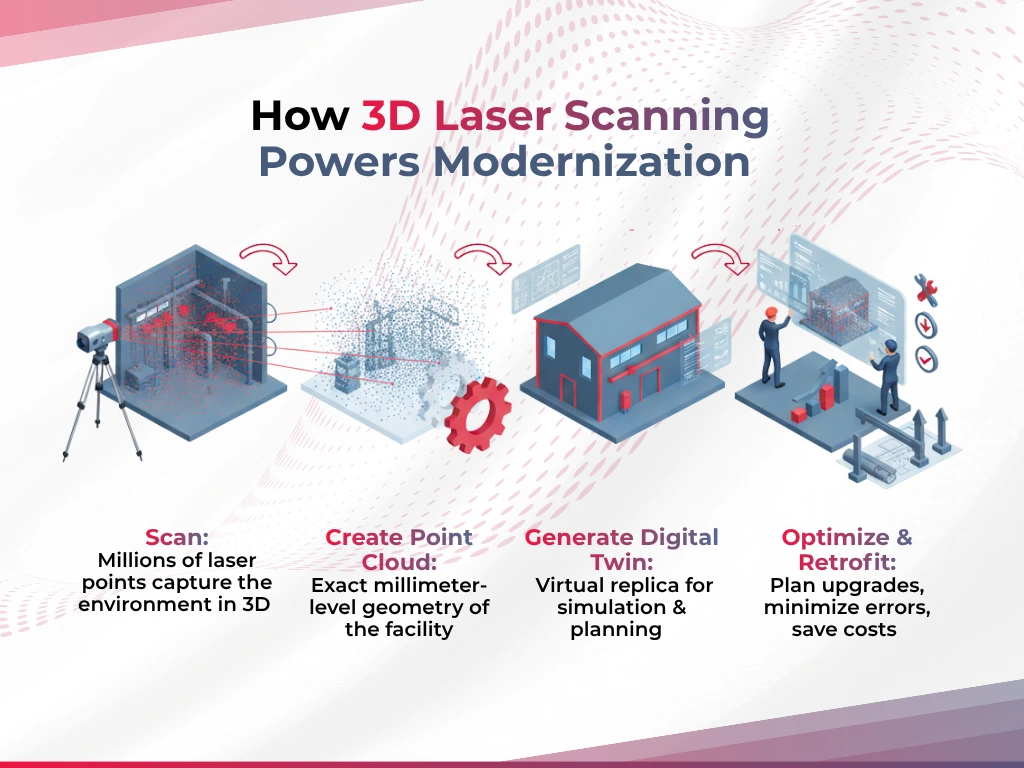

- 3D laser scanning captures these environments with remarkable precision.

- The technology uses millions of laser pulses to measure distances to every surface and creates “point clouds” showing exact geometry.

- Engineers can document complex industrial spaces without disrupting operations.

- The process captures facility data with millimeter-level accuracy.

- These precise scans provide data to modernize facilities.

- ROCKWOOL Ltd’s Welsh facility documented a 9,585 m² area for equipment upgrades using 3D scanning.

- The digital models allowed teams to test configurations virtually before physical changes.

- This approach substantially reduces expensive planning errors.

- The technology excels at reverse engineering legacy equipment.

- Teams can recreate precise models from existing components when CAD drawings are missing.

- This helps extend the useful life of older machinery.

- The scanning process is faster than traditional methods.

- Tasks that once took days of manual measurement now finish in hours.

- Scanning technicians can collect data at rates of 900,000 points per second.

Optimizing Energy Efficiency Through Layout Scanning

Many companies overlook energy management due to perceived high costs, but 3D laser scanning has proven valuable in optimizing energy efficiency. The scan data helps engineers plan layouts that reduce transportation waste, improve workflow, and identify further improvements. Better lighting reduced energy loads by 57%, enhanced HVAC systems lowered cooling by 21,661 kWh, and upgraded double-glazed skylights cut cooling needs by 822 kWh. The detailed point cloud data integrates with CAD software, allowing virtual testing of different setups to find bottlenecks and improve workflows before physical implementation.

Key Aspect | Details |

1. Layout Impact | Layout design affects energy use in manufacturing facilities and plays a key role in sustainability initiatives. |

2. Role of 3D Scanning | 3D laser scanning identifies and applies energy-saving opportunities through exact facility mapping with millimeter accuracy. |

3. Workflow Efficiency | Scan data helps plan layouts that reduce transportation waste, improve workflow, and boost space utilization. |

4. Proven Results | A manufacturing plant improved space usage by 22%, cut forklift travel from 320m to 140m, saving 268 liters of diesel and 719.6 kg CO₂ yearly. |

5. Energy Savings | Plants using 3D scanning have reduced yearly energy use by 5–7%, with some achieving up to 15% savings across multiple machines. |

Supporting Green Manufacturing & Sustainability Certifications

Green certifications have become key indicators of a manufacturer’s environmental commitment, and 3D laser scanning plays a vital role in achieving them. The technology provides precise, verifiable documentation needed for certification audits like LEED. By capturing exact measurements, scan-to-BIM services help facilities validate compliance with building codes, perform energy analyses, and document material resources. This accuracy reduces waste by eliminating trial and error, enabling digital prototyping and better material efficiency.

Start building a sustainable future today. Get free 3D Laser Scanning consultation for your project.

Use Cases of Smart and Sustainable Factories

3D laser scanning delivers measurable sustainability results in a variety of industrial settings. Through collaboration with factory360 GmbH, BHS Corrugated showed how this technology makes a difference; their millimeter-precise digital facility mapping eliminated many site visits and cut CO2 emissions. The technology also cut material waste because components were manufactured with exact measurements that fit perfectly on site.

- A specialty compound manufacturer’s story shows these benefits clearly. The company needed to upgrade three manufacturing lines.

- The team captured the facility’s infrastructure over a weekend with 3D scanning, which kept operations running smoothly.

- They created a digital twin that sped up design changes, reduced downtime, and shortened the project timeline.

- The technology proved valuable at Emerson College’s Little Building too.

- The scanning helped complete an embodied carbon study that showed salvaged materials held over 4,000 metric tons of CO2 equivalent. This amount matches what Boston Common’s forest would store over a hundred years.

- Smart manufacturing initiatives have shown impressive results.

- Manufacturers report output improvements of 10% to 20%, productivity gains of 7% to 20%, and capacity increases of 10% to 15%.

- Asahi Iron Works’ story adds to these successes. The company saved 140 million yen in planned expansion costs by managing their facility operations digitally.

- These examples show how scanning-based smart factory solutions benefit both the environment and the bottom line.

Conclusion:

3D laser scanning has quietly become one of the most influential technologies reshaping modern manufacturing. What began as a tool for precision measurement has evolved into a catalyst for smarter, greener operations. Across legacy facilities struggling with outdated blueprints, laser scanning delivers millimeter-accurate digital twins that eliminate guesswork, cut planning errors, and turn modernization into a data-driven science.

The efficiency story is compelling. Factories using scan data to redesign layouts are reducing material waste, shortening transport routes, and fine-tuning lighting and HVAC systems, all leading to measurable energy savings, sometimes as high as 15%. The ripple effect goes far beyond utility bills; it’s transforming how manufacturers plan, verify, and sustain their operations.

Just as importantly, 3D scanning is becoming a cornerstone of environmental accountability. From LEED and ISO 14001 to B Corp and FSC certifications, the technology provides the kind of verifiable documentation and digital prototyping that sustainability auditors rely on. Every scan tells a story of reduced waste, optimized energy, and smarter resource use.

Real-world results make the case undeniable. Companies like BHS Corrugated have slashed site visits, minimized downtime, and boosted production capacity through digital facility mapping. The evidence points to one conclusion: 3D laser scanning isn’t just supporting the next generation of manufacturing, it’s defining it. It bridges the gap between innovation and responsibility, giving factories the blueprint for a future where operational excellence and sustainability go hand in hand.

Frequently Asked Questions (FAQs):

1. How does 3D laser scanning improve factory efficiency?

3D laser scanning captures precise digital measurements of factory spaces, creating accurate 3D models for layout optimization and equipment planning. This helps manufacturers reduce errors, improve workflow, and minimize downtime leading to 10–20% productivity gains and up to 15% energy savings.

2. Can 3D laser scanning help older factories modernize?

Yes. Legacy facilities often lack accurate blueprints, making upgrades difficult. 3D laser scanning generates millimeter-accurate “as-built” data, allowing engineers to retrofit plants, reverse-engineer old equipment, and plan modernization projects without disrupting ongoing operations.

3. How does 3D laser scanning support sustainability and green certifications?

The technology provides verified documentation for certifications like LEED, ISO 14001, B Corp, and FSC. It helps manufacturers perform energy modeling, material tracking, and embodied carbon studies – reducing waste, optimizing energy use, and improving compliance with environmental standards.

4. What kind of energy savings can manufacturers expect with 3D laser scanning?

Factories using scan-based layout optimization have reported 5-15% yearly energy savings. Benefits include reduced lighting loads (up to 57%), improved HVAC performance, and better space utilization sometimes improving energy efficiency by 22%.

5. Which industries benefit the most from 3D laser scanning?

3D scanning is widely used in manufacturing, construction, industrial retrofits, and facility management. Companies like BHS Corrugated and Asahi Iron Works have used it to cut CO₂ emissions, reduce material waste, and save millions in expansion or redesign costs.

Further Reading

Applications & Risk Management of 3D Laser Scanning in Oil & Gas

3D Laser Scanning for Digital Twin Implementation in Power Plants

Comprehensive Guide on As-Built Surveys

How to Conduct 3D Laser Scanning in Data Centers and Choose the Right Tools?

Comprehensive Guide to 3D Laser Scanning for Power Plants

3D Laser Scanning in Manufacturing: Execution, Tools & Industrial Applications

Our Services

Latest Post

Get A Free Quote

BIM Construction is the Future

Building information modeling (BIM) is the future of building design and construction. Get in touch with our BIM Experts.