Did you know that laser scanning in construction can reduce project costs by as much as 20%?

Table of Contents

ToggleThis innovative technology employs lasers to measure objects and spaces with incredible precision, typically within 1-2 millimeters. 3D laser scanning creates highly detailed digital models of buildings and areas. The best part? It completes measurements in hours instead of days.

3D laser scanning is a non-destructive technology. It works by emitting laser light and measuring the distance between the scanner and object. This process creates what’s known as a “point cloud” of data. Construction professionals can capture as-built documentation of buildings and sites with 2-4mm precision in most cases.

The technology’s impact reaches way beyond the reach and influence of construction. 3D laser scanning has become essential in a variety of industries including architecture, engineering, manufacturing, and heritage preservation. The technology provides unique accuracy and efficiency whether you’re planning a new build, renovating an existing structure, or documenting historical sites.

This detailed guide will show you everything about 3D laser scanning and LiDAR technology, from simple principles to practical applications that can revolutionize your next project.

Understanding Laser Scanning in Surveying

Laser scanning has altered the map of spatial data capture and processing in surveying. This technology creates three-dimensional spatial data as a point cloud through laser beams. The system captures millions of precise measurements quickly, replacing what would take days or weeks with conventional methods.

Laser scanners work by sending out laser pulses and measuring their return to calculate exact distances. The scanners “paint” the surrounding environment with infrared light and capture detailed geometry as objects reflect the beam back. Modern scanners can capture up to two million points per second, creating complete datasets that eliminate the need to revisit sites.

Surveying applications use three main types of laser scanners:

- Time-of-Flight Scanners: These calculate the exact time a laser pulse takes to bounce back from a target object. The formula Distance = (Speed of Light × Time-of-flight)/2 helps them cover large ranges, some models reach up to 2,500 meters. These scanners excel at scanning mines, tunnels, and large outdoor landscapes.

- Phase-Based Scanners: These work through phase shift measurements between outgoing and returning signals and offer better precision than time-of-flight models. Their scanning range typically extends to 300 meters, making them perfect for building interiors and medium-range applications.

- Triangulation Scanners: These capture micron-level details at close range (0.5-2m) using trigonometric calculations with three elements: the scanner, camera, and object. They achieve precision up to 0.01mm but face challenges with reflective or transparent surfaces.

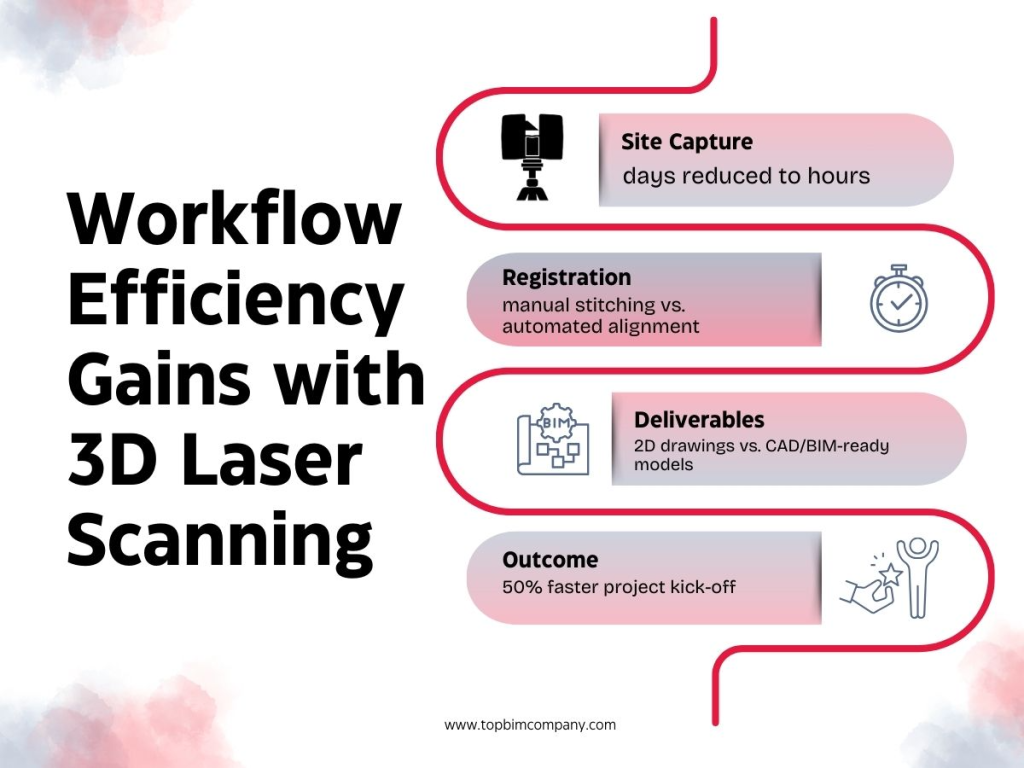

The laser scanning process follows a well-laid-out workflow. It starts with the original consultation and planning, moves to on-site scanning with strategic scanner placement, continues with data processing to merge multiple scans, and ends with conversion into deliverables like 2D drawings or 3D models.

The American Society of Civil Engineers reports this technology has cut data collection times by about 50% compared to traditional surveying methods.

Start building a sustainable future today. Get free 3D Laser Scanning consultation for your project.

Industries Benefiting Most from Laser Scanning

3D laser scanning technology brings substantial returns on investment to many industries.

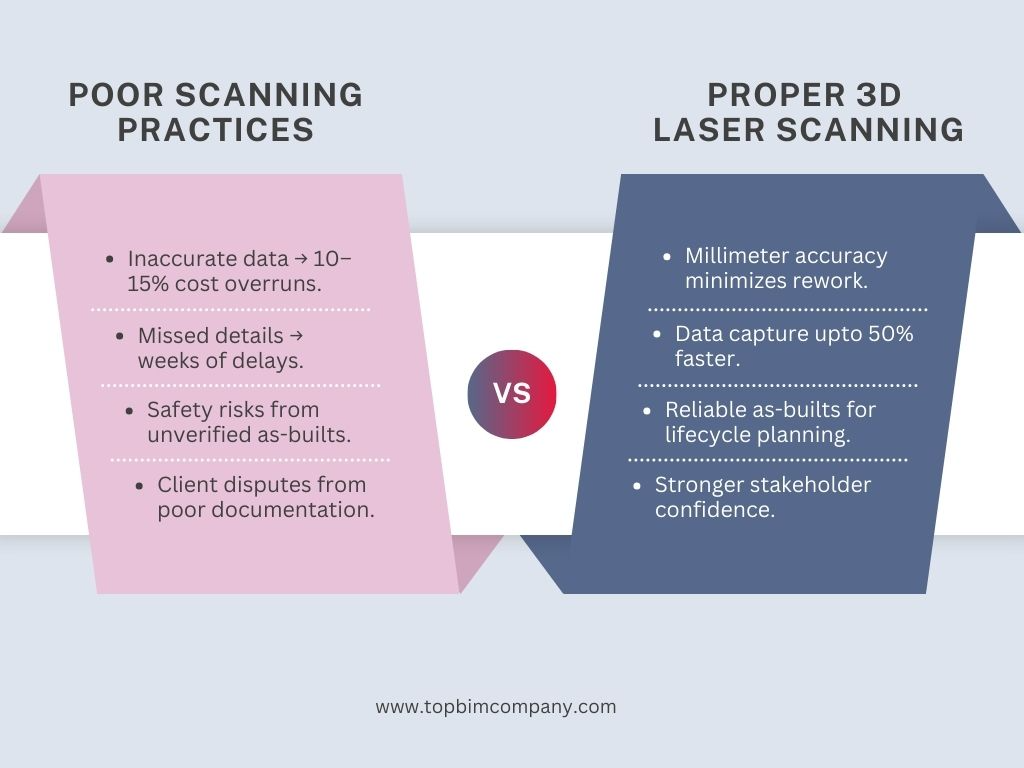

The construction industry will see laser scanning grow by USD 10 billion by 2024. This technology saves up to 50% in costs compared to traditional 2D scanning methods. Quality improvements and reduced rework come as additional benefits. Construction teams get instant information that creates permanent as-built records for owners and facility managers.

- Oil and gas operations come with unique challenges – high risks, tight schedules, and strict standards. Teams can capture and model complex assets with millimeter accuracy without shutting down facilities. The technology helps with as-built documentation, design validation, asset tracking, and remote inspections. Project costs range from USD 5,000-30,000 based on scope. The ROI shows through less field rework, safer operations, and better maintenance planning.

- Heritage preservation has transformed through laser scanning. Teams can now create complete 3D mesh models to archive structures that might need restoration. Organizations can document, study, and monitor cultural artifacts with unprecedented precision. What used to take weeks of manual measurement now takes just days.

- Manufacturing facilities benefit from laser scanning’s precise measurements for design, engineering, and maintenance planning. Teams collect data faster with minimal site disruptions. The technology lets teams virtually bring manufacturing sites to their office, which makes project execution better.

The investment costs might seem high at first, but these industries see clear returns – fewer assumptions, better accuracy, and simplified processes save time and money while producing better project results.

Selecting the Right Service Provider- Quality checklist, vendor questions

Your project’s success depends heavily on selecting the right laser scanning provider. Industry leaders who have worked with thousands of buildings and millions of square feet suggest that service providers vary significantly in their quality of results.

The evaluation of potential partners should begin with their core business focus. Companies that specialize in laser scanning often deliver better results than those who offer it as a secondary service. Their experience in your industry and understanding of your project requirements also plays a crucial role.

Here are some key questions to ask before making your decision:

- How well does the scanner maintain data quality at high speeds? This includes completeness, cleanliness, geometric accuracy, range noise, and mixed pixel filtration.

- What methods do they use for in-field registration and data management?

- What relevant project experience can they demonstrate?

- Do they have all the required software licenses for your project?

- Can they adjust their scope based on your specific requirements?

A thorough quality check must verify equipment calibration, battery levels, target placement, resolution settings, and quality control procedures. Top providers use professional-grade equipment such as Leica P-series scanners to capture exact dimensions with millimeter precision.

Experience stands out as the most crucial factor. Companies with decades of industry expertise can effectively handle challenges and provide accurate documentation in their first attempt.

Step-by-Step Laser Scan Data Processing- Point cloud, CAD/BIM conversion, software table

Laser scan data needs a well-laid-out workflow to become usable deliverables. Cloud computing can turn point-cloud data into practical building information models within hours.

Multiple scans must line up into a unified coordinate system during registration. This crucial step combines millions of data points from different scanner positions. The next phase cleans the data by removing noise, reflections, people, vehicles, and other unwanted elements to enhance accuracy.

Clean point clouds can produce different deliverables:

- CAD conversion requires segmenting the point cloud to identify individual objects before surface reconstruction and CAD format conversion.

- BIM models emerge when the data goes into modeling software where building components take shape based on the point cloud.

Scanning projects usually cover 100,000 square feet daily, and cloud computing processes the data within hours. The highest detail levels achieve precision within a single millimeter.

Common processing software includes:

Software | Main Functions | Automation Level |

Autodesk ReCap Pro | Point cloud interpretation for Revit | Semi-automated |

Leica Cyclone | Registration, visualization, analysis | Human-assisted |

FARO SCENE | Registration, VR visualization | Interactive |

Trimble RealWorks | Point cloud management, 3D modeling | State-of-the-art |

Point cloud data, 2D CAD drawings, 3D BIM models, and virtual tours make up the typical final deliverables.

Laser Scanning vs LiDAR – Which to Choose? – Comparison table, scenarios

Professionals often mix up laser scanning and LiDAR technologies because they look similar. In fact, while both depend on laser technology, each serves a unique purpose based on scale, application, and technical specifications.

These technologies’ range capabilities set them apart. LiDAR works best for long-range scanning, which makes it perfect for mapping large landscapes and civil engineering projects. Laser scanning shines in medium to short-range applications and captures detailed features of buildings or smaller-scale projects.

Here are the main differences:

Feature | Laser Scanning | LiDAR |

Range | Medium to short-range (up to 360m) | Long-range for large areas |

Speed | Slower with greater precision | Rapid data collection |

Accuracy | Higher precision in small-scale conditions | Slightly lesser precision in small applications |

Cost | Budget-friendly for smaller projects | Generally more expensive |

Best For | Building interiors, industrial components | Terrain mapping, urban landscapes |

Technology | Often uses continuous lasers | Uses laser pulses |

Your project’s scope should guide the technology choice. Construction professionals who need millimeter-level precision for documenting building interiors or industrial facilities will find terrestrial laser scanning ideal. LiDAR proves more efficient for mapping large landscapes or monitoring environmental changes – tasks that laser scanning can’t handle as well.

Each technology creates point clouds differently. Laser scanning’s higher density clouds work perfectly for detailed modeling.

Our Services

Latest Post

Get A Free Quote

BIM Construction is the Future

Building information modeling (BIM) is the future of building design and construction. Get in touch with our BIM Experts.

Conclusion

3D laser scanning and LiDAR technologies have changed how professionals measure and document their work. These powerful tools capture reality with pinpoint accuracy and cut down project timelines and costs.

Laser scanning technology has proven to be a real game-changer because it’s so versatile. Time-of-flight scanners can cover huge ranges. Triangulation scanners capture the tiniest details. The technology adapts to almost any measurement challenge. The structured workflow gives consistent results whatever the project’s complexity.

Many sectors benefit from this technology. Construction companies, oil and gas operations, heritage preservation teams, and manufacturing facilities see clear returns through less rework, better safety, and smarter planning. Teams now have complete digital documentation in days instead of the weeks needed for manual measurement.

Project success depends on picking the right service provider. Quality equipment and technical know-how make all the difference between average and great results. Smart questions about data quality, registration methods, and industry experience will help you find capable partners.

Data processing plays a key role in the scanning workflow. Raw point clouds become usable CAD or BIM models through registration, cleaning, and conversion. Software solutions support this process with specific strengths based on project needs.

Knowing the difference between laser scanning and LiDAR helps teams pick the right tool. Laser scanning works best for detailed, small-scale documentation. LiDAR shines in large-scale landscape mapping. This knowledge lets teams use the right technology based on their project’s scope and accuracy needs.

3D laser scanning will become more affordable and blend with other digital tools as technology advances. Most organizations now focus on how to tap into the full potential of this technology for their needs. Few state-of-the-art solutions offer such big improvements in accuracy, efficiency, and project outcomes across industries of all types.

Frequently Asked Questions (FAQs):

Question: What is the difference between laser scanning and LiDAR?

Answer: Both technologies capture 3D spatial data, but they are used in different contexts. LiDAR is typically applied for large outdoor areas and terrain mapping, while laser scanning is preferred for high-detail building and interior scans.

Question: When should I choose LiDAR over laser scanning?

Answer: LiDAR is best suited for large-scale topographic surveys, corridor mapping, infrastructure planning, and terrain analysis where wide coverage is required.

Question: Can laser scanning and LiDAR be combined?

Answer: Yes, combining laser scanning and LiDAR provides complementary datasets. This approach improves overall accuracy for complex projects involving both buildings and surrounding landscapes.

Question: How does cost compare between the two technologies?

Answer: LiDAR is generally more cost-effective for large-area environmental scans, while laser scanning delivers higher detail at a comparatively higher cost for localized areas.

Question: What industries use both technologies?

Answer: Industries such as surveying, construction, mining, forestry, and urban planning commonly use both laser scanning and LiDAR for accurate spatial data capture.

Further Reading

How As-Built Drawings Ensure Compliance with Building Codes

BIM for Sustainability and Energy Efficiency Modeling

Competitive Advantages Of BIM Automation In The AEC Industry

BIM for Heritage Preservation – Future of Protecting Our Past

Future-Proofing AEC Projects: The Role of BIM in Meeting Both ADA and OSHA Standards