What is Laser Scanning and How Does this Solution Work in Surveying?

Laser scanning services have revolutionized the surveying industry.

Table of Contents

ToggleThe market hit $6.7 billion in 2023. Experts project it will reach $13.3 billion by 2032 at a 7.9% CAGR. Our team has seen this technology transform traditional surveying by giving clients unmatched accuracy and better efficiency.

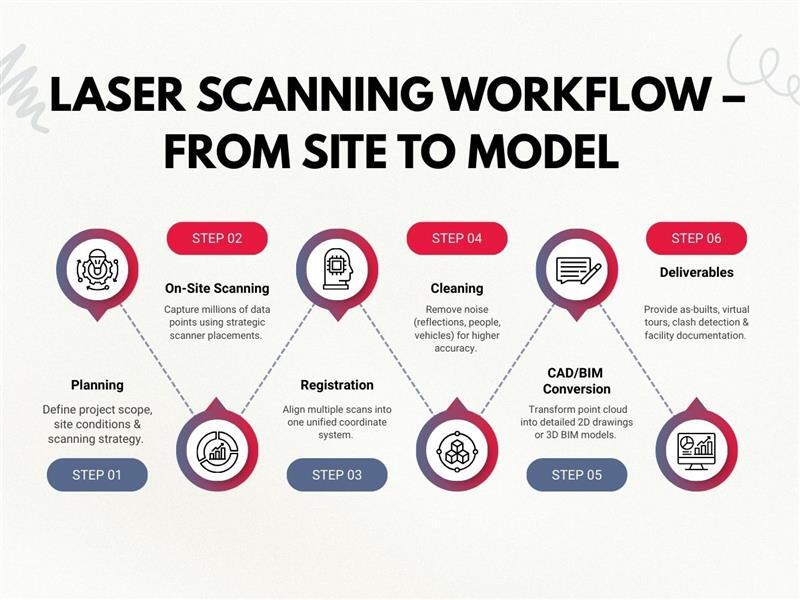

Laser scanning uses high-definition LIDAR (Light, Imaging, Detection and Ranging) technology that captures large amounts of detailed data quickly. These advanced systems collect millions of 3D data points within minutes. Tasks that once took days now wrap up in a single day. Each scan’s precision creates millions of single points that form an exact point-cloud model of a structure.

Businesses gain substantial benefits from this technology. The scans deliver exceptional accuracy and precision. Surveyors gather extensive data in one session, which cuts down fieldwork time. The technology lets teams collect data from safe distances without accessing dangerous areas. Digital twins help measure visible and hidden elements while showing data in different ways.

This piece will look at available laser scanning solutions. You’ll learn why they work better than traditional survey methods. We’ll explore which industries benefit most from this technology and what to think about before choosing a laser scanning provider.

What Types of Laser Scanning Solutions are Available?

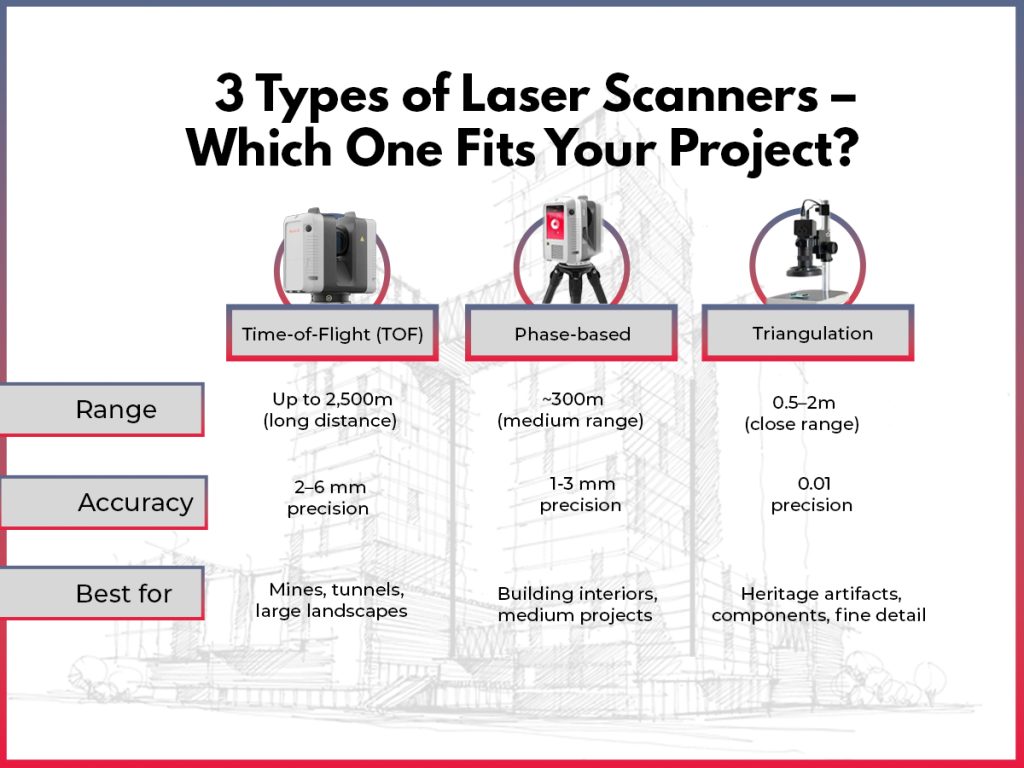

Laser scanning solutions differ based on project needs, site conditions, and expected results. The industry currently features four distinct categories.

- Terrestrial laser scanning systems mount on stationary tripods to capture detailed scans from fixed points. These scanners deliver millimeter-level accuracy that makes them perfect for architectural documentation, construction verification, and heritage preservation projects.

- Mobile laser scanning systems attach to vehicles and collect data on the move. This method works best for mapping transportation infrastructure, pipelines, and corridor surveys where teams need to cover long distances quickly.

- Aerial laser scanning puts LiDAR sensors on aircraft, drones, or helicopters. The systems excel at large-scale topographic mapping, forest inventory, and flood modeling. They can map huge areas rapidly, though with lower point density than ground methods.

- Indoor laser scanning equipment adapts specifically to confined spaces. These specialized systems capture complex interior layouts for facility management, BIM modeling, and space planning with minimal disruption to operations.

Solution Type | Range | Accuracy | Speed | Best Applications |

Terrestrial | 1-1000m | 1-5mm | Moderate | Detailed buildings, Complex structures |

Mobile | 1-200m | 5-20mm | Fast | Roads, Railways, Corridors |

Aerial | 10-3000m | 5-30cm | Very Fast | Topography, Large areas |

Indoor | 0.5-30m | 1-3mm | Moderate | Interiors, Confined spaces |

Why Choose Professional Laser Scanning Services Over Traditional Survey Methods?

Laser scanning services have revolutionized the surveying industry that relied on traditional methods for decades. These services give projects a significant edge over conventional techniques that depend on manual measurements. The technology achieves millimeter-level precision throughout project sites.

The difference in speed stands out, especially when you have large projects. Traditional surveys could take weeks in the field and need extensive office work afterward. A laser scanner captures millions of data points in just one day. This speed leads to lower labor costs and quicker project completion times. The original investment in laser scanning equipment pays off quickly through time savings alone.

The detailed nature of laser scanning data helps avoid getting pricey fixes later. Traditional methods often need return trips to the field for missing measurements. Laser scanning creates a complete dataset teams can check anytime they need to.

The benefits become obvious when we examine the whole picture:

Benefit Category | Traditional Surveying | Laser Scanning Services |

Accuracy | Centimeter-level | Millimeter-level precision |

Data Collection | Selective points only | Comprehensive capture |

Time Efficiency | Weeks for complex sites | Days whatever the complexity |

Risk Mitigation | Limited visibility | Complete documentation |

Project Costs | Lower initial cost, higher risk | Higher initial investment, lower total cost |

Design Integration | Manual conversion required | Direct import to CAD/BIM |

Laser scanning creates a complete digital record that teams can rely on throughout their project’s lifecycle, unlike traditional methods.

Which Industries Rely on Laser Scanning Expertise?

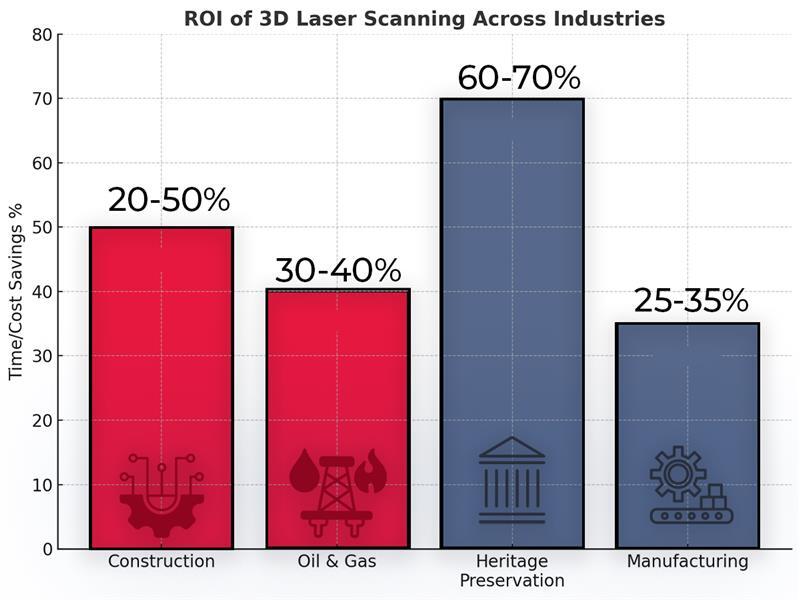

Laser scanning services have transformed four major industries with their unique capabilities.

Construction companies use laser scanning to create precise as-built documentation and detect clashes. To name just one example, a $50 million commercial project team found structural conflicts through laser scanning. These issues would have cost $2.3 million in rework if found during construction.

- The oil and gas sector benefits from this technology’s accurate facility modeling capabilities. A recent offshore platform project created a detailed digital twin through laser scanning. This allowed safe modernization planning without shutting down the facility and saved $175,000 daily in potential production losses.

- Heritage preservation teams rely heavily on laser scanning to document historical structures. A cathedral’s restoration team created an exact digital archive of its architectural features. This effort preserved centuries of craftsmanship digitally for future generations.

- Manufacturing plants use laser scanning to improve their production layouts. An automotive plant’s team adjusted their assembly lines using scan data and achieved a 15% boost in production efficiency. The plant’s operations continued during the scanning process, which eliminated expensive downtime.

These industries share a common thread: laser scanning delivers unmatched precision, speed, and data capture that traditional methods can’t achieve. This explains why accuracy-focused industries increasingly adopt this technology.

Key Considerations Before Partnering with a Laser Scanning Provider

Your success in laser scanning surveys depends on reviewing several important factors when choosing the right partner.

- A realistic budget should account for your project’s complexity. Scanner type, data resolution and post-processing requirements drive the pricing structure.

- The costs might look higher than traditional surveying at first. But think over the long-term value – detailed 3D documentation cuts down expensive rework and serves as lasting reference material.

- Your project scope needs clear definition. List your specific deliverables (point clouds, CAD models, BIM assets) and mark areas that need scanning.

- Share site plans, point out possible obstructions and let them know about time constraints. This preparation helps get accurate quotes and the work runs smoothly.

- The technical expertise of potential providers needs a thorough review. Look for specialists who have relevant industry experience and right equipment that matches your needs.

- Ask for sample deliverables and case studies to see their capabilities. Check their quality control process and verify their insurance coverage.

Note that the cheapest option rarely gives the best value. Focus on finding a service provider who knows your industry’s unique requirements and can give you applicable information that combines smoothly with your existing workflows.

Conclusion

Laser scanning technology is pioneering modern surveying and gives businesses clear advantages over conventional methods. This piece explores how these advanced systems capture millions of 3D data points in minutes with millimeter-level precision.

Each of the four main scanning solutions, terrestrial, mobile, aerial, and indoor, meets specific project needs based on accuracy, range, and application. Businesses need to pick the right scanning method for their requirements. Laser scanning outperforms traditional surveying techniques through complete data capture. It cuts down fieldwork time and boosts safety by removing the need to access dangerous areas.

Many sectors have seen real benefits from laser scanning services. Construction firms, oil and gas operations, heritage preservation specialists, and manufacturing facilities report strong returns on investment. These come through prevented rework costs, reduced production losses, preserved historical data, and better operational efficiency.

Companies should review their budget limits and define project scope clearly before choosing a laser scanning provider. They must also check the technical expertise of potential partners carefully. The right provider will know your industry’s specific needs and deliver applicable information that blends with existing workflows naturally.

Laser scanning isn’t just another option for conventional surveying. It’s a game-changing approach that builds lasting value through digital documentation. The complete, accurate datasets serve as reliable references throughout a project’s lifecycle. This leads to smarter decisions and better project results. As the technology grows, companies that welcome laser scanning will benefit from better accuracy, efficiency, and data visualization capabilities.