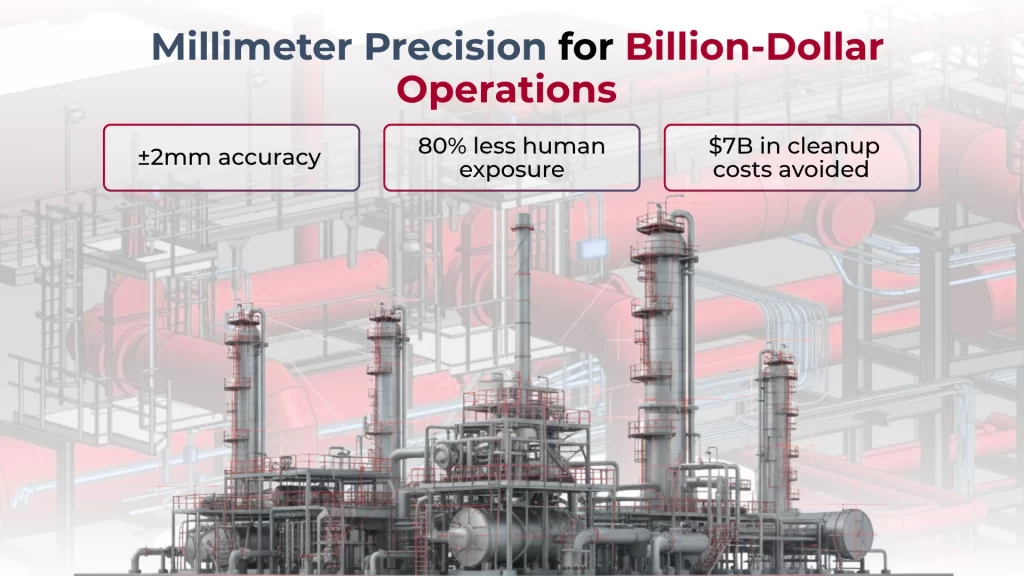

3D laser scanning technology captures millions of measurement points with sub-centimeter accuracy, typically within ±2 to 3 millimeters. This precision reshapes the scene in oil and gas projects and creates safer workplaces with more efficient operations.

Table of Contents

ToggleSafety hazards pose real challenges in the industry. The CDC recorded 602 injury incidents over just two years. That’s why reducing human intervention matters so much. 3D laser scanning uses high-speed LiDAR to create detailed point clouds that show the exact shape, size, and spatial relationships of physical environments. Teams now rely on this technology to improve every project phase with accurate, efficient, and safe benefits.

Environmental protection becomes crucial since 64% of spills in hydraulic fracturing reach surrounding soil and 7% contaminate nearby surface water. Teams can now pre-plan routes, material staging, and clash detection with confidence thanks to precise monitoring and super-accurate mapping of environmental hazards.

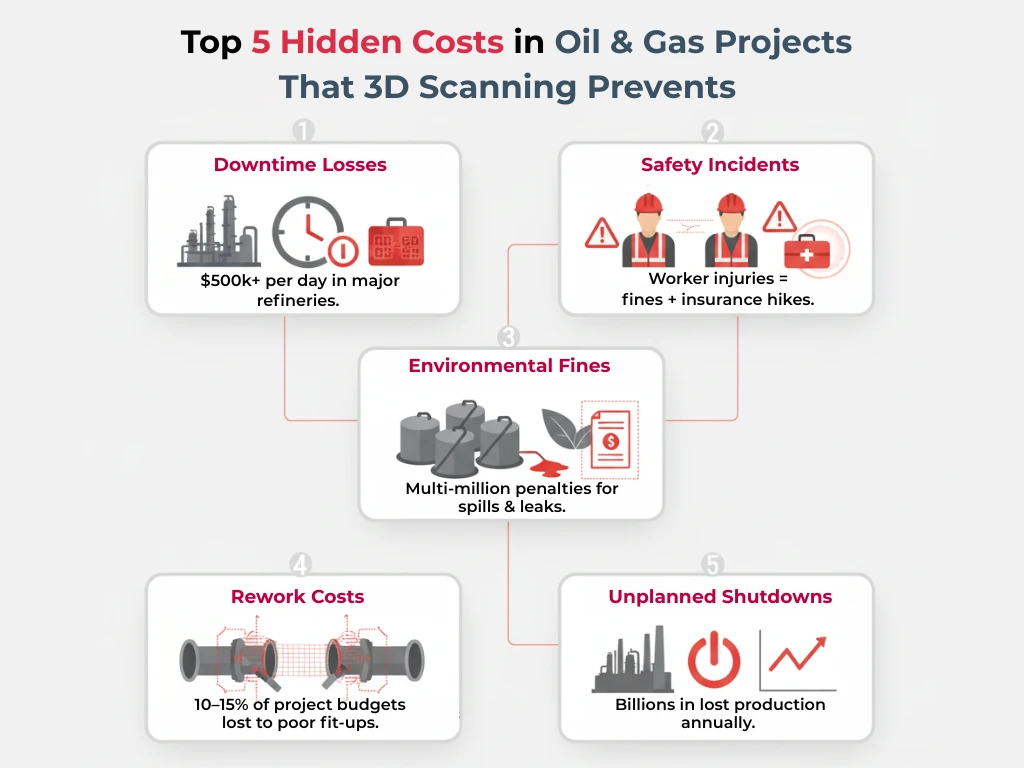

Most operations find the investment worthwhile. Oil and gas projects typically cost between $5,000 to $30,000+. These numbers make sense when compared to the $7 billion in cleanup costs the industry faces.

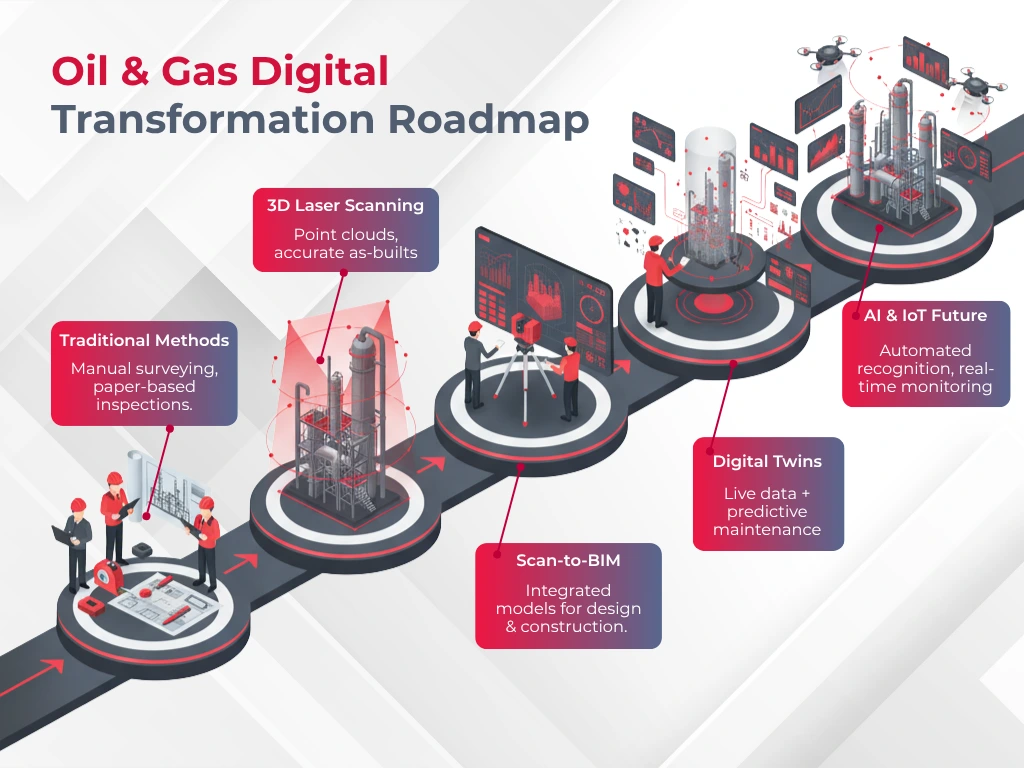

The scan-to-BIM process gives teams major advantages over traditional methods by capturing millions of data points in minutes for very precise measurements.

This piece explores how 3D laser scanning reshapes the oil and gas industry. You’ll learn about the tools, technologies, and practical applications that can make your operations safer, more efficient, and environmentally responsible.

Tools & Technologies for Oil & Gas Facilities

Scanning tools used in oil and gas projects have changed by a lot in the last decade. Modern scanners now capture more than 1 million measurement points every second. These scanners create digital replicas that mirror physical facilities with amazing accuracy.

- Ground-based terrestrial laser scanners are still the go-to choice for most oil and gas work. These units are portable and deliver high-accuracy measurements (typically ±2mm at 10m range).

- Phase-based scanners work best in refineries and processing facilities because they balance speed and precision well. Time-of-flight systems are great for long-range work like pipeline corridors and large tank farms.

- Mobile scanning has become popular because it’s a quick way to document large facilities. These systems mount on vehicles or backpacks and combine LiDAR with inertial measurement units and GNSS technology.

- They create accurate point clouds while moving and cut field time by about 80% compared to static setups.

- Drone-mounted LiDAR is a great option for hard-to-reach areas or offshore platforms. These flying systems capture detailed data without needing framework or confined space entry. They can also use thermal and multispectral sensors to spot corrosion, leaks, and structural problems at the same time.

- Data processing has grown up too. Point cloud registration software handles billions of points quickly, and smart algorithms spot pipes, vessels, and structural elements automatically. This makes it easier to turn raw scans into smart 3D models.

- Reality capture software bridges field data and engineering applications. Engineers can spot clashes between existing conditions and planned changes, which stops costly field rework. They can see complex spatial relationships without entering dangerous areas.

- Digital twin platforms are the biggest breakthrough yet. These dynamic models mix 3D geometry with up-to-the-minute data analysis. They create living digital copies that track everything from pressure changes to equipment temperatures. This makes preventive maintenance work much better.

Applications in Oil & Gas Operations

3D laser scanning technology now plays a vital role at every stage of the oil and gas value chain and provides practical solutions to age-old industry challenges. The technology’s benefits go far beyond simple measurement, from the original site surveys to decommissioning processes.

- Scanning creates precise topographic models that help optimize well pad placement and access road construction during exploration and development. These models calculate cut-and-fill volumes for earthworks and identify environmental constraints before ground breaking begins.

- Laser scanning has become an essential quality control tool in facility construction. Field teams exploit scan data to verify installation’s match with design specifications, which ended up preventing work that could get pricey. Engineers use as-built scans of existing facilities to design new components that fit perfectly on the first attempt.

- The technology’s role in asset integrity management proves crucial. Teams can measure deformation, corrosion, and settlement over time by scanning critical equipment regularly. This approach helps maintenance crews spot potential failures early instead of responding to emergencies.

- Pipeline operations see similar advantages from this technology. Right-of-way scans detect encroachments, geohazards, and unauthorized construction near pipelines. Specialized internal scanning tools document the pipe’s wall thickness variations and weld quality with millimeter precision.

- Scanning documents platform conditions on offshore facilities without sending personnel into hazardous areas. This reduces safety risks and operational downtime compared to traditional inspection methods.

The technology is a great way to get detailed records during decommissioning. These records support thorough planning for dismantling operations and environmental remediation efforts.

Accuracy, Compliance & Safety

Category | Key Points |

Accuracy | – ±2mm precision at 10–30m range |

Compliance | – Meets ASME B31.3 (process piping) |

Safety | – 80% less staff exposure to hazards |

Reliability | – Data validation with registration checks |

Foundation | – Supports compliance & safety protocols |

Start building a sustainable future today. Get free 3D Laser Scanning consultation for your project.

Common Mistakes in Oil & Gas 3D Scanning

The most important advances in 3D laser scanning technology haven’t prevented avoidable mistakes that still impact project success in oil and gas applications. Poor scan planning stands out as the main goal that derails projects.

- Teams often underestimate the coverage they need and leave data gaps that hurt the model’s integrity. The biggest problem comes from weak registration techniques.

- Point clouds don’t arrange correctly without enough overlap between scans – you need about 30-40%. This leads to measurement errors that spread through the whole model.

- Outdoor scanning faces tough challenges from nature. Data quality suffers from high temperatures, rain, and equipment vibrations nearby.

- Teams should schedule their scans during good weather and make sure their equipment stays stable, but many don’t take these steps.

- Resolution choices often go wrong because technicians use the same settings everywhere. Different facility areas need different detail levels – pipe racks need sharper scans than open spaces. Still, many teams stick to uniform settings throughout their projects.

- Messy data management creates problems later. Even perfectly captured scans become useless without proper file names and organization. This gets worse as projects grow bigger.

- Maybe even the most basic mistake is not having enough training. The fanciest scanning equipment won’t help if operators don’t understand its limits, best practices, and how to process the data properly.

Real Life Use Cases – Successful Oil & Gas Facility Scanning

Success stories from the ground show how valuable 3D laser scanning can be in oil and gas applications of all types.

- A prominent North American refinery discovered major differences between their documents and actual site conditions. Their engineers used over 500 million data points from 50 scan positions to spot spatial conflicts. This early detection helped them avoid work that would have gotten pricey during their planned expansion.

- The team at an offshore platform in the North Sea went through a full facility scan before upgrading their equipment. They completed the entire scan in just five days instead of the three weeks needed with old methods. This quick turnaround saved them about $175,000 in downtime costs.

- Pipeline operators have seen great results too. A scan of a 120-mile pipeline corridor revealed hidden encroachments and possible geohazards along the right-of-way. The team created a 3D model that helped operations staff plan maintenance based on actual risks rather than random inspection schedules.

These wins came from good execution and avoiding the mistakes we discussed earlier. The best projects share key features- solid planning, the right technology choices, good environmental conditions, and proper data checks.

These examples show the real benefits of well-implemented 3D scanning technology. Oil and gas facilities can now get accurate digital records to support safer operations, quicker modifications, and better regulatory compliance.

Conclusion:

The rise of 3D laser scanning signals a decisive shift in how oil and gas companies will operate in the future. Its precision and adaptability are not just incremental improvements over traditional methods, they redefine how safety, compliance, and efficiency are approached across the industry.

Firms that integrate scanning into their workflows will move beyond reactive maintenance and fragmented documentation toward predictive planning and fully digital asset management. As regulations tighten and risks grow more complex, reliance on accurate digital records will no longer be optional but expected.

The real advantage, however, lies in competitiveness. Organizations that embrace laser scanning today are not simply reducing hazards or cutting costs, they are positioning themselves as leaders in a safer, smarter, and more sustainable oil and gas sector.

Frequently Asked Questions (FAQs):

1. What is 3D laser scanning in the oil and gas industry?

3D laser scanning is a technology that captures millions of precise measurement points (±2–3 mm accuracy) using LiDAR to create detailed point clouds of physical environments. It helps with design, construction, maintenance, and safety in oil and gas projects.

2. How accurate is 3D laser scanning for oil and gas projects?

Modern scanners achieve sub-centimeter accuracy, typically ±2 mm, which surpasses traditional survey methods and ensures highly precise measurements for construction, inspection, and monitoring.

3. How does 3D laser scanning improve safety in oil and gas operations?

It reduces human exposure to hazardous environments by up to 80%, allows virtual planning for confined spaces, and enables remote inspections, especially on offshore platforms, minimizing injury risks.

4. What types of 3D laser scanners are used in oil and gas facilities?

Ground-based terrestrial scanners for high-accuracy facility mapping.

Phase-based scanners for refineries and processing plants.

Time-of-flight systems for long-range pipelines and large tanks.

Mobile scanners on vehicles or backpacks for rapid large-area scans.

Drone-mounted LiDAR for hard-to-reach or offshore locations.

5. How is 3D laser scanning applied across oil and gas operations?

Applications include:

Exploration and development: topographic modeling, well pad planning, and environmental constraint mapping.

Construction: quality control and as-built verification.

Asset integrity: monitoring deformation, corrosion, and settlement.

Pipelines: right-of-way scans and internal inspections.

Offshore platforms: condition documentation and remote inspection.

Decommissioning: planning dismantling and remediation.

6. What is the scan-to-BIM process, and why is it important?

Scan-to-BIM converts point cloud data into intelligent 3D models for design, construction, and maintenance. It reduces rework, improves spatial planning, and integrates digital models with engineering applications.

7. How does 3D laser scanning help with environmental compliance?

By mapping hazards and spill-prone areas, scanning allows teams to plan material staging, detect potential environmental risks, and avoid fines from contamination of soil or water.

8. What are common mistakes in oil and gas scanning projects?

Poor scan planning and coverage gaps.

Inadequate point cloud registration (less than 30–40% overlap).

Ignoring weather and environmental conditions.

Using uniform resolution for all areas.

Poor data management and lack of operator training.

9. Can 3D laser scanning save money for oil and gas projects?

Yes. While scans cost $5,000–$30,000+, they prevent expensive rework, reduce downtime, improve safety, and avoid billions in cleanup costs, fines, and unplanned shutdowns.

10. What are real-life examples of successful 3D laser scanning in oil and gas?

A North American refinery used 500 million data points to detect spatial conflicts during expansion.

A North Sea offshore platform completed scans in 5 days instead of 3 weeks, saving $175,000 in downtime.

Pipeline operators identified hidden encroachments and geohazards, improving maintenance planning.

Further Reading

How to Process Laser Scan Data and Select the Right Scanning Provider or Technology?

Ultimate Guide to 3D Laser Scanning & LiDAR Scanning

Comprehensive Guide on As-Built Surveys

How to Conduct 3D Laser Scanning in Data Centers and Choose the Right Tools?

Comprehensive Guide to 3D Laser Scanning for Power Plants

How to Use As-Built Surveys in Renovation Projects and Avoid Common Mistakes?

How to Conduct an As-Built Survey and Choose the Right Tools for Your Project?

Our Services

Latest Post

Get A Free Quote

BIM Construction is the Future

Building information modeling (BIM) is the future of building design and construction. Get in touch with our BIM Experts.