3D laser scanning systems have revolutionized asset management in the oil and gas industry, where precision and accuracy cannot be compromised. These advanced technologies create accurate digital representations of complex infrastructure within minutes instead of days or weeks by capturing detailed spatial data.

Table of Contents

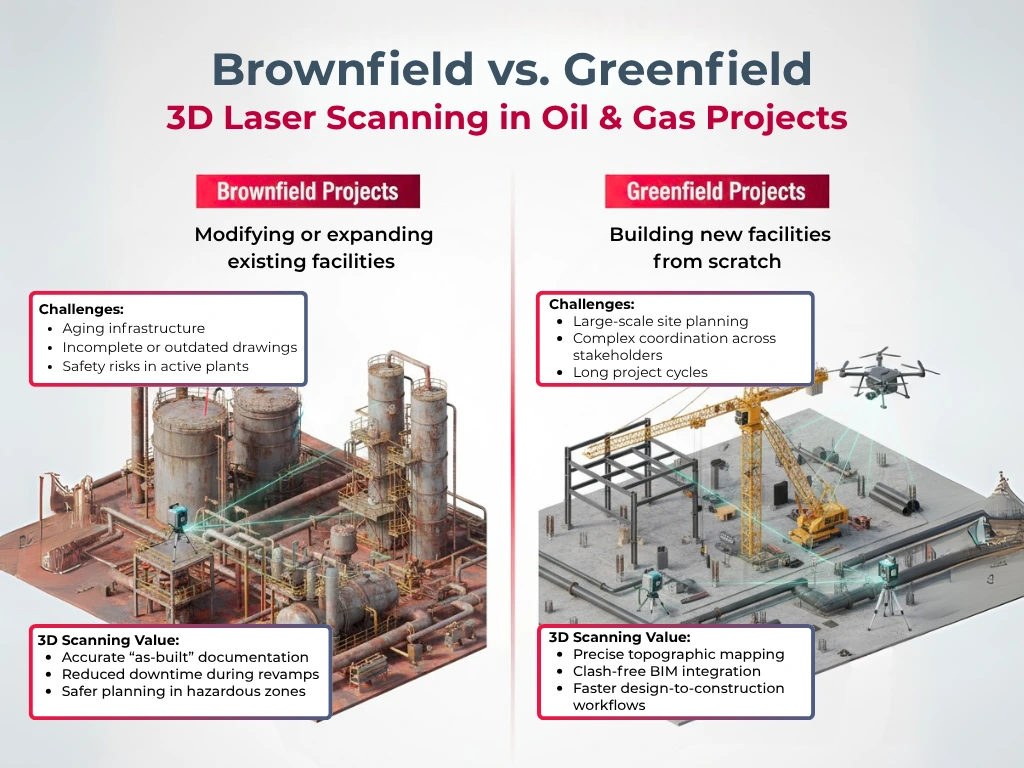

ToggleLaser scanning proves its worth in modernize and revamp projects. Error rates from traditional manual measurements typically range between 10-30% in field data collection and get pricey to fix.

3D laser scanning achieves millimeter-level accuracy that reduces documentation errors by up to 95% and cuts project costs by 5-7%.

From As-Built Gaps to Digital Twins: The New Standard in Asset Management

Many aging facilities lack accurate engineering drawings or have changed without documentation.

- Laser scanning technology offers a quick solution to bridge this “as-built” documentation gap. These systems can capture complete spatial data of entire processing units in just one day. The resulting digital records are the foundations for maintenance, modification, and expansion work.

- The investment in laser scanning makes sense from a safety perspective alone. These systems reduce safety risks by limiting personnel exposure in dangerous areas. Research shows remote scanning techniques cut onsite worker hours by 60% during data collection.

Laser scanning creates lasting operational advantages. The detailed digital assets help with:

- Better inspection and maintenance planning

- Less downtime during turnarounds

- Better teamwork between engineers

- Better contractor coordination

- Efficient regulatory compliance

The complete laser scanning data serves as the backbone for digital transformation projects. Point clouds generated by these scans work as the framework for digital twins, IoT systems, and predictive maintenance programs. This creates a digital foundation for modern asset management strategies.

3D laser scanning has become essential for progressive oil and gas operators as regulations become stricter and operational margins shrink.

Pre-Scan Safety Measures and Site Preparation

Planning and safety measures must come first when you deploy 3D laser scanning in oil and gas environments. These technologies reduce project risks, but the pre-scanning phase needs careful attention to safety protocols and site preparation.

Safety should be your top priority during scanning operations. Laser scanning technology makes work safer by reducing the need for scaffolding, ladders, and entry into confined spaces. Eye protection needs special attention because laser beams can cause serious injury—especially from higher-class devices. You can minimize this risk by using proper protective eyewear and barriers.

A complete site assessment needs to happen before moving equipment:

- Access Points and Limitations :Identify entry points and restricted areas

- Environmental Conditions :Check temperature, lighting, dust, and potential interference factors

- Safety Considerations :Use appropriate protective gear and stay aware of hazards.

Site access timing needs clear communication, especially when you have restricted locations like processing plants. Check if you need safety training or security clearance before arrival. Active facilities require all necessary permits and compliance with health and safety regulations.

Equipment preparation is a vital pre-scan step. Make sure all scanning equipment works and is properly adjusted:

- Check battery levels for entire scan session requirements

- Confirm tripod stability and positioning

- Verify calibration settings are current

- Ensure sufficient data storage capacity

The staff should receive proper training on equipment operation, data interpretation, and emergency procedures. This knowledge prevents accidents and physical damage at work. Safety protocols stay fresh through regular workshops and on-the-job training.

These pre-scan measures offer benefits beyond safety. To name just one example, teams spend less time in hazardous facilities, which makes the project safer. Good preparation also reduces unwanted disruptions and keeps the scanning process aligned with safety standards.

Comparing Workflows- Onshore vs. Offshore Operations

Laser scanning workflows are different between onshore and offshore oil and gas facilities. Each type comes with its own challenges and things that just need to be done. Onshore facilities give you a more controlled environment. Offshore platforms make things trickier because they’re remote and always changing.

- Onshore operations give scanner mobility a big advantage. Teams can move their equipment between locations in regular vehicles and finish multiple scans in one day. Safety zones are the main thing limiting access, not transportation issues.

- The stable ground also gives teams a reliable platform to work from, so they don’t need special equipment to deal with movement.

Offshore scanning takes much more planning. Teams must move their equipment by helicopter or boat, and everything needs special packaging to handle the marine environment.

- The weight and size of scanners really matter because moving anything offshore can get pricey. Floating platforms never stop moving, so teams need advanced stabilization tech to keep their scans accurate.

- Weather barely affects onshore scanning but can stop offshore work completely. Strong winds, rain, or extreme temperatures often cause delays. Teams need flexible schedules and backup plans. These delays usually make projects take 20-30% longer than similar work onshore.

Here’s how the core operations match up:

Factor | Onshore Operations | Offshore Operations |

Equipment Transport | Standard vehicles | Helicopters/vessels |

Scan Time | Typically 1-2 days | Often 3-5 days for similar scope |

Environmental Challenges | Limited | Significant (weather, motion) |

Data Transfer | High-speed connections | Limited bandwidth satellite |

Personnel Requirements | Smaller teams | Larger teams with marine certifications |

Data handling shows another big difference. Onshore teams usually have fast networks to transfer data right away. Offshore teams deal with slow connections, so they must process data on board or physically transport it. Teams must check data quality before leaving to avoid expensive return trips.

Both environments benefit from new portable, tough 3D laser scanning systems. These systems handle rough conditions while staying accurate down to the millimeter.

Advanced Tools & Technologies in Oil & Gas 3D Scanning

Tool / Technology | Primary Use | Key Features | Oil & Gas Value |

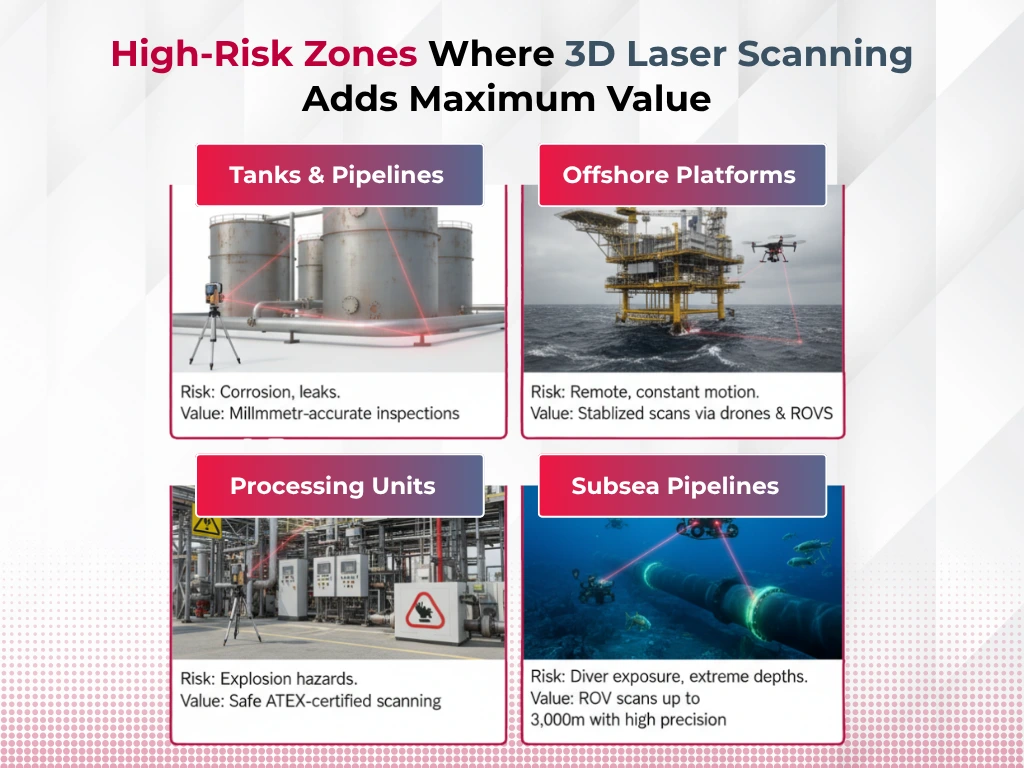

ATEX-Certified Scanners (e.g., Imager 5006EX) | Explosion-risk areas in processing units, pits, tanks, pipelines | – Explosion-proof (Group I & II certified) | Safe scanning in hazardous zones without worker exposure |

Fixed-Wing VTOL Drones with LiDAR | Surface surveys & pipeline corridors | – Cuts through vegetation | Boosted uptime in maintenance (e.g., vapor recovery unit uptime from 60% → 99%) and $500K+ annual savings |

ROVs (Remotely Operated Vehicles) with Laser Scanners | Subsea pipelines & underwater infrastructure | – Resolution 100x higher than acoustic methods | Eliminates diver risk, captures accurate data without stopping operations |

Deliverables & Value for Engineers, Contractors, and Asset Owners

3D laser scanning produces valuable outputs that benefit the oil and gas value chain. The key outputs from these systems include precise point cloud data, detailed 2D CAD drawings, detailed 3D BIM models, and interactive viewers like TruView. Users can access these outputs in various formats (.e57, .rcs, .dwg, .rvt) that work seamlessly with industry-standard software such as AutoCAD, Revit, and SolidWorks.

Engineers benefit from unprecedented accuracy—within millimeters. This eliminates guesswork and creates reliable digital twins that reflect real-life conditions instead of theoretical ideals. The system’s precision allows 100% pre-fabrication before project implementation and eliminates expensive rework.

Many producers now require laser scanning for bid eligibility, giving contractors a competitive edge. The technology cuts down field verification time by capturing detailed data in one visit and minimizes costly return trips.

Asset owners see the most significant benefits through better asset documentation, condition monitoring, and maintenance support. The system can scan stockpiles to estimate quantities accurately and make tank calibration more precise. Most projects recover their investment within 9 months and see 40-50% faster time-to-market.

The financial benefits go beyond direct savings. Reduced downtime, better safety measures, and longer asset lifecycles work together to maximize return on investment.

Start building a sustainable future today. Get free 3D Laser Scanning consultation for your project.

Integration with Digital Twins & Asset Management System

3D laser scanning systems paired with digital twin technology mark a breakthrough in the oil and gas sector. Digital twins create virtual copies of physical assets that monitor and simulate different scenarios. These digital versions work as accessible spatial indexes to find vital asset data.

Quick 3D scanning methods feed these twins with exact point cloud data. The result? Precise virtual models that match ground conditions. These scans prove more reliable than older BIM or CAD models.

The models’ merger with enterprise asset management (EAM) systems improves operations significantly. This process needs three vital types of data:

- A 3D point cloud

- Images of the area

- GeoTags connecting physical assets to digital versions

Companies that add live sensor data to these models see remarkable results.

Case studies show a 90% drop in data processing time and 25% better field operations. Asset owners can see vital measurements like temperature or valve conditions right on their digital twin.

This technology does more than just show data. It spots problems before they get pricey and helps predict maintenance needs. Smart maintenance scheduling cuts downtime and extends equipment life. This shows how technology creates excellence even in tough environments.

Conclusion

On refinery floors and offshore rigs, where workers once balanced on scaffolding with clipboards and tape measures, scanners now hum quietly, capturing millions of data points in seconds. The change is not just technological; it’s cultural. Engineers no longer argue over measurements but over models, contractors share data in real time, and maintenance teams plan around digital replicas instead of paper drawings that may or may not be accurate.

The technology’s appeal is also pragmatic. As one project manager in the Permian Basin noted, “It saves money, but more importantly, it saves hours in places we’d rather not send people.” That sentiment resonates in an industry where safety is as valuable as speed, and where reputational risk from accidents can be as costly as operational downtime.

Yet the shift is not without challenges. Scanners must still contend with hostile marine environments, bandwidth bottlenecks offshore, and the steep learning curve of data-heavy workflows. Smaller operators worry about costs, even as early adopters argue the investment pays back within a year. But the momentum is unmistakable. Analysts see 3D scanning as a foundational layer for digital twins, predictive maintenance, and even future AI-driven plant operations.

What emerges is a picture of an industry in transition: not abandoning the old, but overlaying it with new precision. As regulations tighten and margins narrow, oil and gas companies are embracing tools that allow them to see more, risk less, and act faster. If the last century of energy infrastructure was built on steel and labor, the next may well be built on point clouds and pixels, an invisible architecture shaping the physical world, one millimeter at a time.

Frequently Asked Questions (FAQs):

1. How does 3D laser scanning improve safety on-site?

It reduces personnel exposure to hazardous areas by limiting the need for scaffolding, ladders, or entry into confined spaces, cutting onsite worker hours by up to 60%.

2. What accuracy can I expect from 3D laser scanning?

TopBIM’s 3D laser scanning achieves millimeter-level precision, reducing documentation errors by up to 95% compared to traditional manual measurements.

3. Can 3D laser scanning be used for both onshore and offshore operations?

Yes. Onshore scanning benefits from controlled environments and mobility, while offshore scanning requires advanced stabilization and careful planning for marine conditions.

4. What types of oil & gas facilities benefit most from 3D laser scanning?

Tanks, pipelines, offshore platforms, processing units, and subsea pipelines all benefit from millimeter-accurate inspections and safer, faster data collection.

5. How does 3D laser scanning support digital twin creation?

The scans generate point cloud data that form the backbone of digital twins, enabling real-time monitoring, predictive maintenance, and integration with enterprise asset management systems.

Further Reading

Comprehensive Guide to 3D Laser Scanning for Oil & Gas

Ultimate Guide to 3D Laser Scanning & LiDAR Scanning

Comprehensive Guide on As-Built Surveys

How to Conduct 3D Laser Scanning in Data Centers and Choose the Right Tools?

Comprehensive Guide to 3D Laser Scanning for Power Plants

How to Use As-Built Surveys in Renovation Projects and Avoid Common Mistakes?

How to Conduct an As-Built Survey and Choose the Right Tools for Your Project?

Our Services

Latest Post

Get A Free Quote

BIM Construction is the Future

Building information modeling (BIM) is the future of building design and construction. Get in touch with our BIM Experts.