Get detailed shop drawings tailored to your needs from TopBIM Company, a leading provider of shop drawing services in the USA, India, Canada, UAE, and Europe.

Table of Contents

Toggle

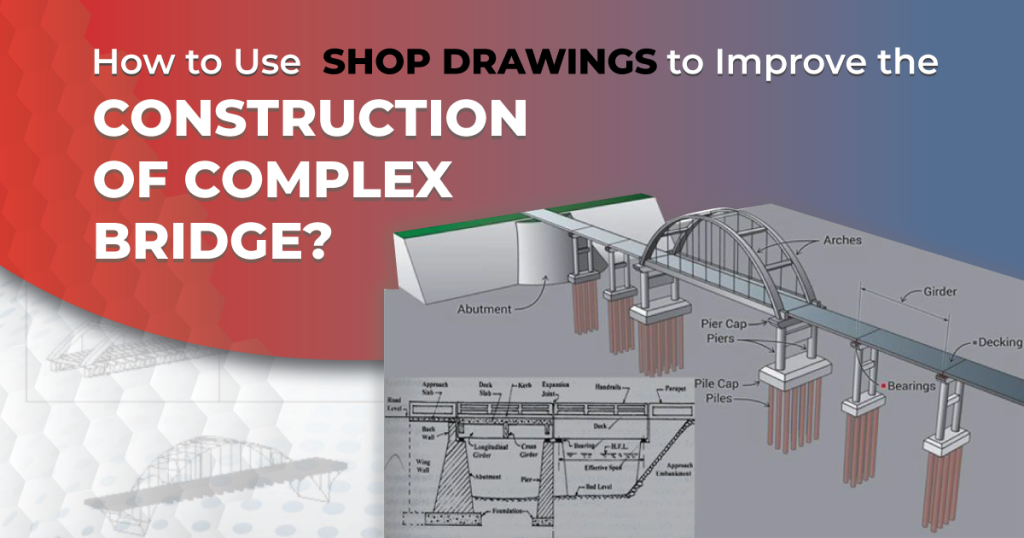

Understanding Complex Bridge Construction

Complex bridge construction projects are often characterized by their large scale, complex design, and challenging construction conditions. Some unique challenges that may be encountered in such projects include:

Topological challenges while constructing a bridge in difficult terrains:

Topological challenges are those that arise from the physical characteristics of the terrain, such as its steepness, ruggedness, and inaccessibility. These challenges can make it difficult to construct and inspect bridges in difficult terrains.

- Difficult access to the construction site: It can be difficult to transport materials and equipment to the construction site in difficult terrains.

- Steep and rugged terrain: Steep and rugged terrain can make it difficult to construct a stable foundation for the bridge.

- Geological instability: Geological instability, such as landslides and earthquakes, can pose a significant challenge to bridge construction in difficult terrains.

- Extreme weather conditions: Extreme weather conditions, such as high winds, heavy snow, and flooding, can also make bridge construction difficult in difficult terrains.

Inspection difficulties:

Bridge inspection is also difficult in difficult terrains due to the following challenges:

- Inaccessibility: It can be difficult to access the bridge for inspection, especially if it is located in a remote or inaccessible area.

- Hazardous conditions: The hazardous conditions of difficult terrains, such as steep slopes, loose rocks, and turbulent water, can make bridge inspection dangerous.

- Specialized equipment: Specialized equipment may be needed to inspect bridges in difficult terrains, such as rope access equipment or drones.

Importance of Precision and Efficiency:

Precision and efficiency are essential for the successful construction of complex bridges. Even small errors in construction can have serious consequences for the safety and performance of the bridge. Additionally, complex bridge projects often have tight deadlines and budgets, so it is important to minimize delays and cost overruns.

May be you would like to read

How To Create Shop Drawings For Custom Prefabricated Components?

BIM For Shop Drawings: Accurate, Efficient, And Clash-Free

Ultimate Guide To Create Shop Drawings For Construction

How Digitization Simplifies As-Built Documentation In Construction?

Shop Drawings: A Comprehensive Overview

Shop drawings are detailed plans that are used to guide the fabrication and construction of bridges. They are typically prepared by the contractor or subcontractor responsible for the fabrication or construction of a particular component of the bridge. Shop drawings are typically based on the design engineer’s drawings, but they may include additional information, such as fabrication tolerances, assembly instructions, and quality control procedures.

Types of Shop Drawings

Shop drawings are technical drawings that are created by contractors, suppliers, and fabricators to provide detailed information about the construction of a project. Shop drawings are typically required for prefabricated components, such as structural steel, MEP (mechanical, electrical, and plumbing) systems, and architectural millwork.

There are many different types of shop drawings, but some of the most common include:

- Structural shop drawings: These drawings show the details of structural steel components, such as beams, columns, and trusses.

- MEP shop drawings: These drawings show the layout and installation of MEP systems, such as ductwork, piping, and wiring.

- Architectural shop drawings: These drawings show the details of architectural components, such as windows, doors, and cabinets.

- Fabrication shop drawings: These drawings show the details of fabricated components, such as metal stairs and railings.

- As-built drawings: These drawings are created after the construction of a project is complete and show the actual dimensions and installation details of all components.

The Role of Shop Drawings in Bridge Construction

Shop drawings can help to address the topological challenges of bridge construction in difficult terrains in a number of ways. For example, shop drawings can be used to:

- Plan and coordinate construction activities: Shop drawings can be used to develop a detailed plan for the construction of the bridge. This plan can help to identify and mitigate potential challenges, such as difficult access to the construction site and steep terrain.

- Design for constructability: Shop drawings can be used to design the bridge for constructability. This means designing the bridge in a way that is easy to build and assemble, even in difficult terrains.

- Fabricate bridge components off-site: Bridge components can be fabricated off-site and then transported to the construction site. This can help to reduce the amount of time and resources required to construct the bridge, especially in difficult terrains.

- Communicate with contractors: Shop drawings can be used to communicate with contractors and ensure that they understand the design intent. This can help to reduce errors and rework during construction.

Shop drawings for maintenance revisions

Shop drawings can also be used to aid in maintenance revisions. For example, shop drawings can be used to:

- Identify the location and type of maintenance required: Shop drawings can be used to identify the location and type of maintenance required on the bridge. This can help to plan and coordinate maintenance activities efficiently.

- Design and fabricate maintenance components: Shop drawings can be used to design and fabricate maintenance components, such as replacement bridge components or temporary support structures. This can help to ensure that maintenance work is completed quickly and efficiently.

- Communicate with maintenance crews: Shop drawings can be used to communicate with maintenance crews and ensure that they understand the work that needs to be done. This can help to reduce errors and ensure that the bridge is maintained properly.

Overall, shop drawings can play an important role in addressing the topological challenges of bridge construction in difficult terrains and in aiding in maintenance revisions.

Here are some specific examples of how shop drawings can be used to address topological challenges in bridge construction:

- Using shop drawings to plan for difficult access: Shop drawings can be used to develop a detailed plan for transporting materials and equipment to the construction site. This plan can take into account the terrain and identify any potential challenges. For example, if the construction site is only accessible by helicopter, shop drawings can be used to develop a plan for lifting materials to the site safely and efficiently.

- Using shop drawings to design for constructability: Shop drawings can be used to design the bridge in a way that is easy to build and assemble, even in steep terrain. For example, shop drawings can be used to design prefabricated bridge sections that can be assembled on site. This can reduce the amount of time and resources required to construct the bridge.

- Using shop drawings to communicate with contractors: Shop drawings can be used to communicate with contractors and ensure that they understand the design intent. This is especially important in difficult terrains, where there is a greater risk of errors and omissions. For example, shop drawings can be used to show contractors how to safely install bridge components in steep terrain.

By using shop drawings to address topological challenges in bridge construction, engineers can help to ensure that bridges are built safely, efficiently, and to a high standard of quality.

Creating Effective Shop Drawings

Creating effective shop drawings requires a thorough understanding of the bridge design and the construction process. Shop drawings should be prepared by experienced and qualified professionals who are familiar with the latest industry standards and best practices.

Here are some tips for creating effective shop drawings:

- Gather and review design data: The first step in creating shop drawings is to gather and review all relevant design data, such as the design engineer’s drawings, specifications, and calculations.

- Collaborate with design and construction teams: It is important to collaborate with the design and construction teams throughout the shop drawing process. This helps to ensure that the shop drawings are accurate and complete.

- Utilize specialized software and tools: There are a number of specialized software and tools available to assist with the creation of shop drawings. These tools can help to improve accuracy and efficiency.

Software Used for Shop Drawing Creation of Bridges & Structural Analysis of Infrastructural Amenities

- AutoCAD: AutoCAD is a versatile CAD software application that can be used to create shop drawings for a variety of bridge and infrastructural projects. AutoCAD is used to create detailed drawings of bridge components, such as beams, columns, and trusses. AutoCAD drawings can also be used to generate construction schedules and bills of materials.

- Revit: Revit is BIM software application that can be used to create 3D models of bridges and other infrastructural projects. Revit models can be used to generate shop drawings, construction schedules, and other project documentation. Revit can also be used to perform clash detection and other quality control checks.

- Tekla Structures: Tekla Structures is a specialized structural modeling software application that is used to create shop drawings for steel and concrete bridges. Tekla Structures models can be used to generate detailed drawings of bridge components, as well as to produce CNC files for steel fabrication.

- Bentley ProStructures: Bentley ProStructures is a specialized structural engineering software application that is used to design and analyze bridges and other infrastructural projects. Bentley ProStructures can be used to create shop drawings for bridge components, as well as to perform structural analysis and design.

- MicroStation: MicroStation is a CAD software application that is used to create shop drawings for a variety of bridge and infrastructural projects. MicroStation is similar to AutoCAD, but it offers some additional features, such as support for 3D modeling and parametric design.

- ETABS: ETABS is a structural analysis software application that is used to analyze the behavior of buildings and other structures. ETABS can be used to analyze the structural behavior of bridges and other infrastructural amenities under a variety of loads, such as dead loads, live loads, wind loads, and seismic loads.

- SAP2000: SAP2000 is a structural analysis software application that is similar to ETABS. SAP2000 is used to analyze the structural behavior of a variety of structures, including bridges, buildings, and industrial facilities.

- STAAD.Pro: STAAD.Pro is a structural analysis software application that is used to analyze the behavior of a variety of structures, including bridges, buildings, and offshore structures. STAAD.Pro is known for its ability to handle complex structural problems.

- Midas Gen: Midas Gen is a structural analysis and design software application that is used to design and analyze a variety of structures, including bridges, buildings, and offshore structures. Midas Gen is known for its user-friendly interface and its ability to handle complex structural problems.

- CSI Bridge: CSI Bridge is a specialized bridge analysis and design software application. CSI Bridge is used to design and analyze a variety of bridge types, including beam bridges, truss bridges, and cable-stayed bridges. CSI Bridge is known for its accuracy and its ability to handle complex bridge problems.

Future Trends in Bridge Construction and Shop Drawings

The growth of logistics and transportation infrastructure is driving a demand for new and innovative bridge construction methods. Shop drawings can play a vital role in meeting this demand by helping to ensure the efficient and effective construction of bridges.

You would like to read about Role of GIS For Transportation Planning Management

Technology:

Technological advances, such as 3D printing and artificial intelligence (AI), are revolutionizing the shop drawing creation process. 3D printing can be used to create physical prototypes of bridge components, which can help to identify and address potential problems before construction begins. AI can be used to automate the generation of shop drawings from 3D models, which can save time and reduce the risk of errors.

Thorough Maintenance:

Thorough maintenance is essential for extending the lifespan of bridges and ensuring the safety of users. Shop drawings can be used to develop detailed maintenance plans and schedules. They can also be used to track maintenance activities and identify areas where additional maintenance is required.

By leveraging technology, shop drawings can help to ensure the efficient and effective construction and maintenance of bridges, which is essential for supporting the growth of logistics and transportation infrastructure.

Here are some specific examples of how technology can be used to improve the thoroughness of bridge maintenance:

- Drones: Drones can be used to inspect bridges for damage and signs of wear and tear. Drones can also be used to take detailed photos and videos of bridges, which can be used to develop maintenance plans and schedules.

- Sensors: Sensors can be placed on bridges to monitor bridge conditions and identify potential problems early on. For example, sensors can be used to monitor bridge vibrations, deflections, and temperature.

- Data analytics: Data analytics can be used to identify trends in bridge performance and develop proactive maintenance strategies. For example, data analytics can be used to identify bridges that are at risk of failure and to develop maintenance schedules that will help to prevent bridge failures.

Overall, technology can play a vital role in improving the thoroughness of bridge maintenance. By leveraging technology, shop drawings can help to ensure the safe and reliable operation of bridges for many years to come.

Our Services

Latest Post

Get A Free Quote

BIM Construction is the Future

Building information modeling (BIM) is the future of building design and construction. Get in touch with our BIM Experts.